Rotary stack riveted motor rotor core

A rotor core and motor rotor technology, which is applied in the manufacture of squirrel cage rotors, stator/rotor bodies, magnetic circuit rotating parts, etc., can solve the problem that the jump cannot be eliminated, the magnetic circuit of the rotor core is uneven, and the quality of the core is reduced and other problems, to achieve the effect of saving mechanical finishing process, good flatness and consistency, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

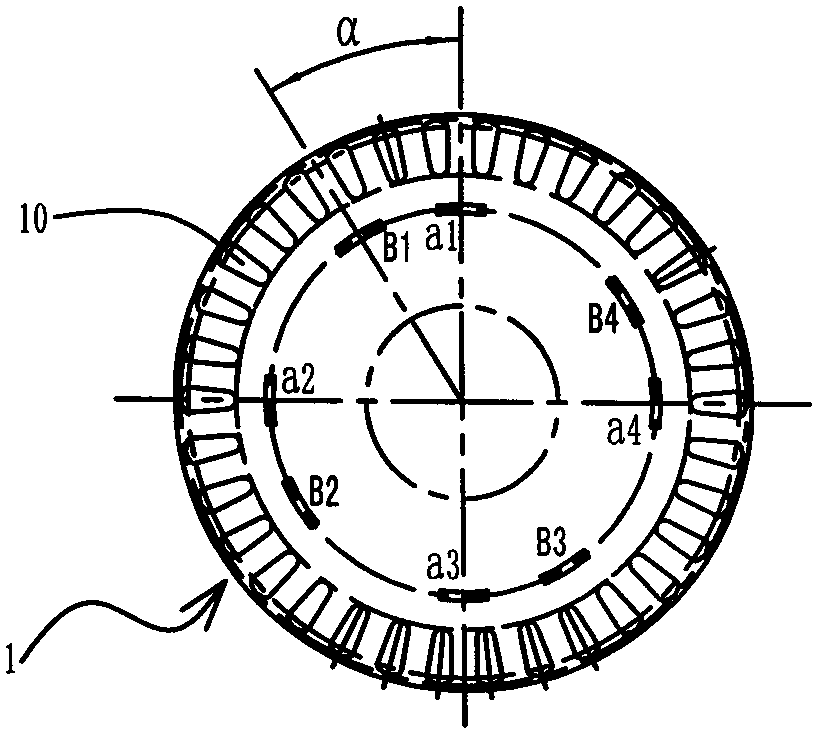

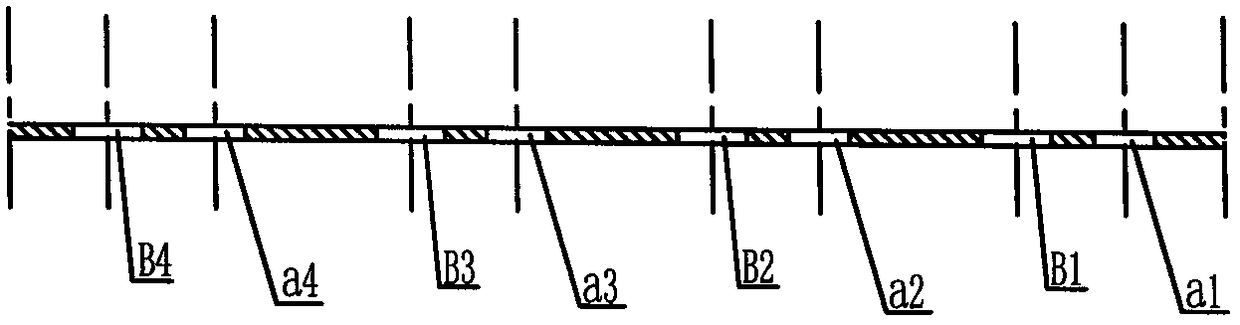

[0054] The illustration of the present embodiment, the adopted material thickness is roughly the bar of d=0.5mm, and the number n=100 of the annular rotor stamping sheets (the number n of the rotor stamping sheets 1 whose sheet thickness is definite is determined by the rotor iron core Depending on the stacking height requirements, the stacking height of the rotor core is H=50mm), the slots of the rotor core to be manufactured and the slots of the stator core are matched as follows: The number of slots Z=24.

[0055] Please refer to Picture 1-1, 1-2 , 1-3, 2-1, 2-2, 2-3, 2-4, 3-1, 3-2, 3-3, 3-4, 4-1, 4-2, 4-3, 4 -4,

[0056] A rotary stack riveting motor rotor core, which is formed by stacking and riveting n circular rotor punches 1 with guide bar grooves evenly distributed at intervals. The number of embedding grooves Z matches.

[0057] Each rotor punch 1 has an inner circle, the above-mentioned number of guide grooves 10, an outer circle, four rivets (a1, a2, a3, a4) a...

Embodiment 2

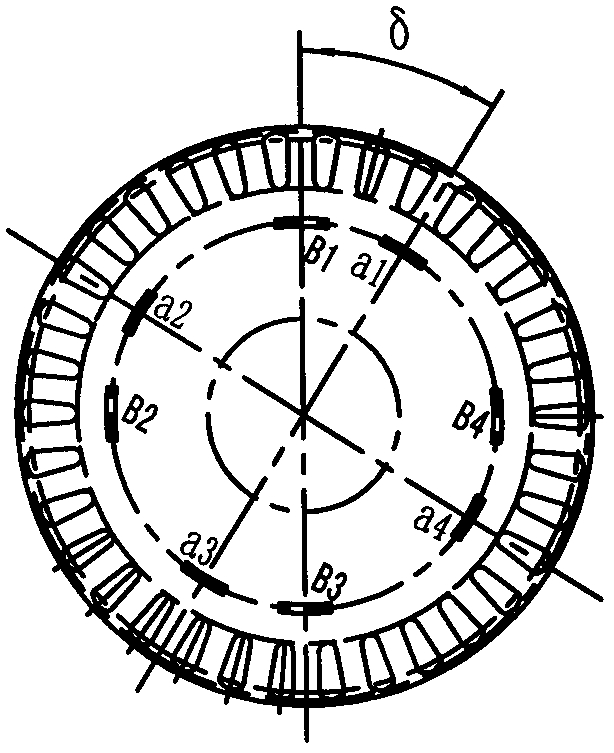

[0080] The illustration of the present embodiment, the adopted material thickness is roughly the bar of d=0.5mm, and the number n=100 of the annular rotor stamping sheets (the number n of the rotor stamping sheets 1 whose sheet thickness is definite is determined by the rotor iron core The stacking height is determined by the stacking height of the rotor core (H = 50mm). The slots of the rotor core and stator core to be manufactured are matched as follows: the number of guide bar slots for the rotor core is Q = 34, and the embedded wires of the stator core The number of slots Z=24.

[0081] Please refer to Figure 5-1 , 5-2 , 5-3, 6-1, 6-2, 6-3, 6-4, 7-1, 7-2, 7-3, 7-4, 8-1, 8-2, 8-3, 8 -4,

[0082] A rotary stack riveting motor rotor core, which is formed by stacking and riveting n circular rotor punches 1 with guide bar grooves evenly distributed at intervals. The number of embedding grooves Z matches.

[0083] Each rotor punch 1 has an inner circle, the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com