Elastic supporting mechanism, optical component driving mechanism, image pick-up device and electronic equipment

A technology of elastic support and shrapnel, which is applied in the direction of optical components, optics, installation, etc., can solve the problems of increased cost, large posture difference, inconsistent shaking of double shrapnel, etc., to ensure camera accuracy and stability, improve driving accuracy, and shrink The effect of poor posture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] like Figure 9 and Figure 10 As shown, the base 2 is used to fix the circuit board 3 and carry a single carrier 4 .

[0056] like Figure 5 As shown, the circuit board 3 includes a middle circuit portion 30 , and reinforcing members are embedded in the middle region of the middle circuit portion 30 so as to improve the structural strength of the middle circuit portion 30 .

[0057] One end of the circuit board 3 is connected with a power terminal 33 for easy connection with a power source.

[0058] like Figure 5 and Figure 12-13 As shown, there are two circuit side portions 31 and they are distributed oppositely. The circuit side portion 31 is connected to the circuit middle portion 30 and is used for electrical connection with the Y-axis coil 6b.

[0059] The circuit slope portion 32 is located between the two circuit side portions 31 and slopes above the circuit middle portion 30 . The circuit inclined portion 32 is used to electrically connect the inclined ...

Embodiment 2

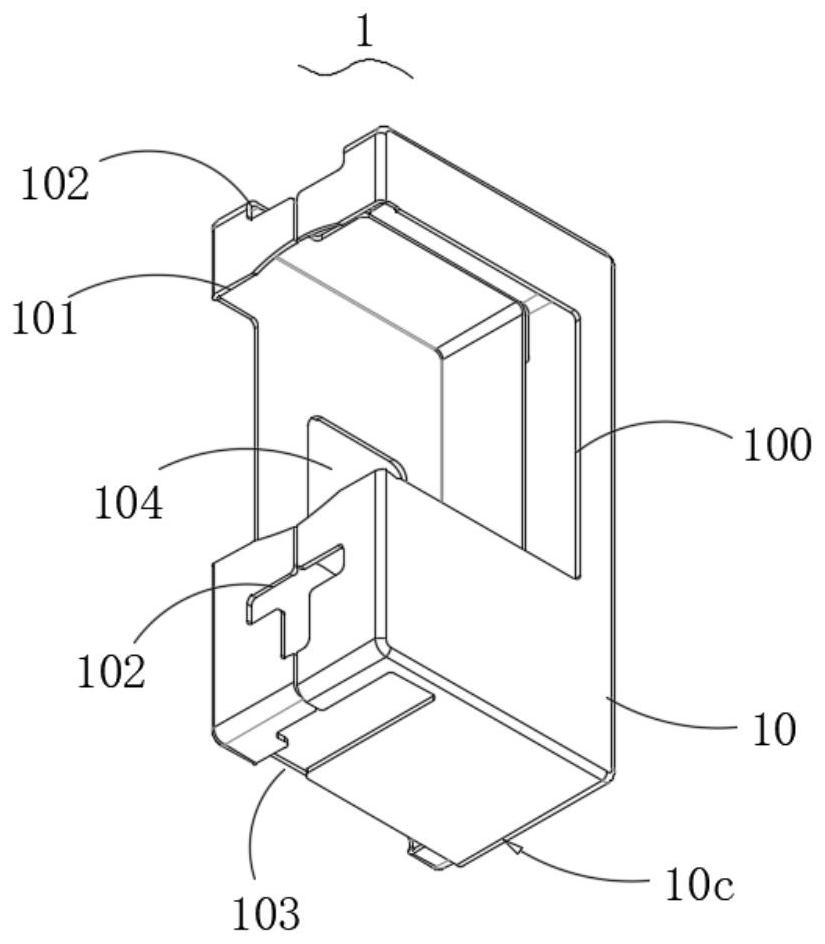

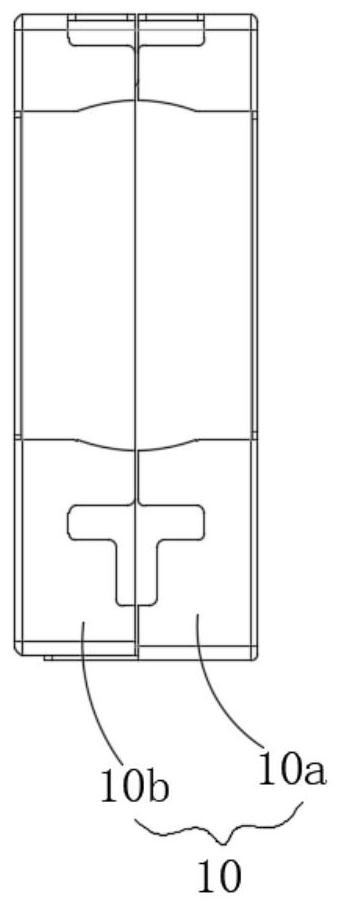

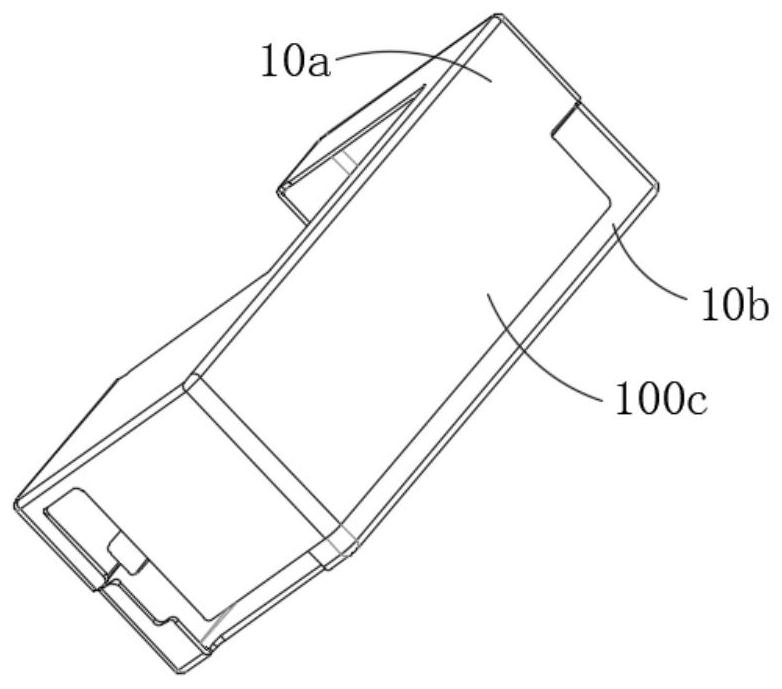

[0198] On the basis of the first embodiment above, as Figure 4 and Figure 9 As shown, the present invention also provides an optical component driving mechanism L. The arrows in the figure represent the light-incoming and light-emitting directions. The optical component driving mechanism is used to adjust the X / Y-axis position of the prism L0 to meet the use requirements. This embodiment has the housing 1 and the base 2 as described in the first embodiment above, and the circuit board 3 is fixed on the base 2. There is a single-carrier accommodation space in the base 2, and the single-carrier 4 is installed in the single-carrier accommodation space through an elastic support mechanism. In this embodiment, a Y-axis electromagnetic drive mechanism and an inclined X-axis electromagnetic drive mechanism are provided to drive the single carrier 4 .

Embodiment 3

[0200] On the basis of the above-mentioned embodiment two, as Figure 17 As shown, the present invention also provides an imaging device, which has the optical component driving mechanism L as described in the second embodiment above, and the lens driving mechanism T. The lens driving mechanism T is located at the light exit port 101. Using the optical component driving mechanism L Changing the optical path and synergizing with the lens driving mechanism T can realize high-precision and ultra-clear camera work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com