Deep foundation pit quality supervision method

A deep foundation pit, high-quality technology, applied in image data processing, special data processing applications, 3D modeling, etc., can solve problems affecting the final quality of engineering projects, relatively high professional and experience requirements for supervisors, and many participants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

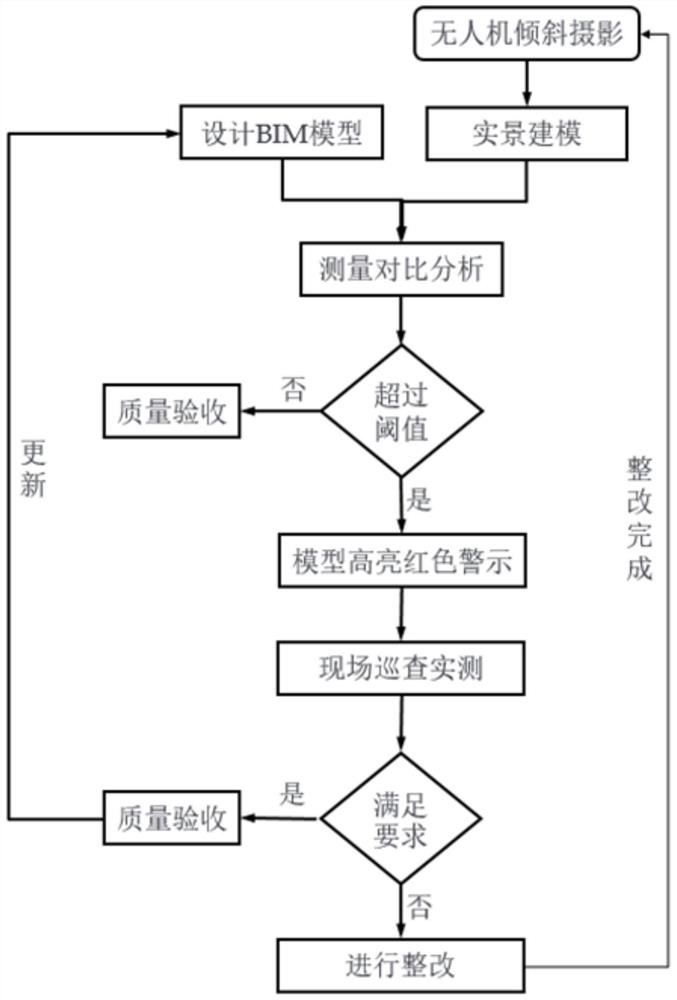

[0030] see figure 1 , shown in the figure is a deep foundation pit quality supervision method, including the following steps:

[0031] In step S10, the unmanned aerial vehicle is used to take oblique shots of the construction site, and collect the side texture and position information of the ground objects on the construction site. In this embodiment, the unmanned aerial vehicle preferably adopts the unmanned aerial vehicle produced and designed by Dajiang Company.

[0032] Step S20, processing the obliquely captured images to generate a fused overall mesh model, and establishing a 3D real-scene model of the deep foundation pit according to the overall mesh model. In step S20, use ContextCapture software to process the obliquely captured image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com