High-flux high-voltage polarization device

A high-flux, high-voltage technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, electrical components, circuits, etc., to avoid threats to personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

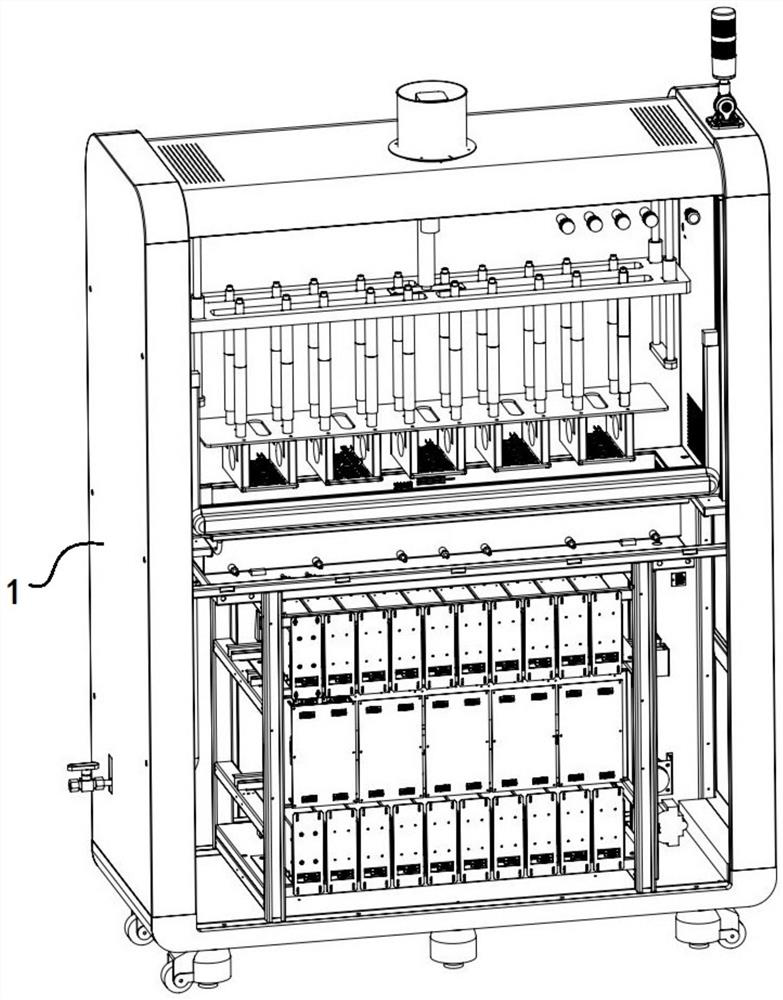

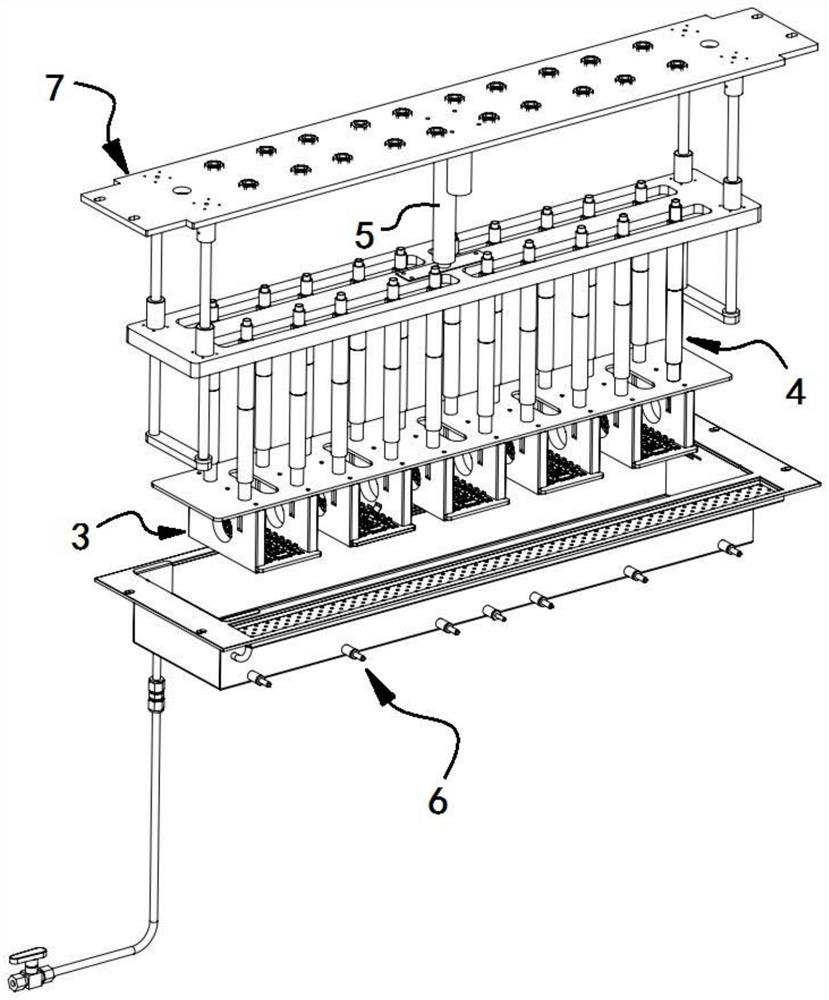

[0038] The invention provides a high-throughput high-voltage polarization device, such as figure 1 and figure 2 As shown, it includes a frame 1, at least one first polarized probe 2, a clamping assembly 3, at least one second polarized probe 4 and a driving assembly 5. The frame 1 is formed by splicing profile plates, and the frame 1 can be In any shape, in this embodiment, the frame 1 is a cabinet composed of profiles and boards.

[0039] The first polarized probe 2 is fixed on the frame 1 .

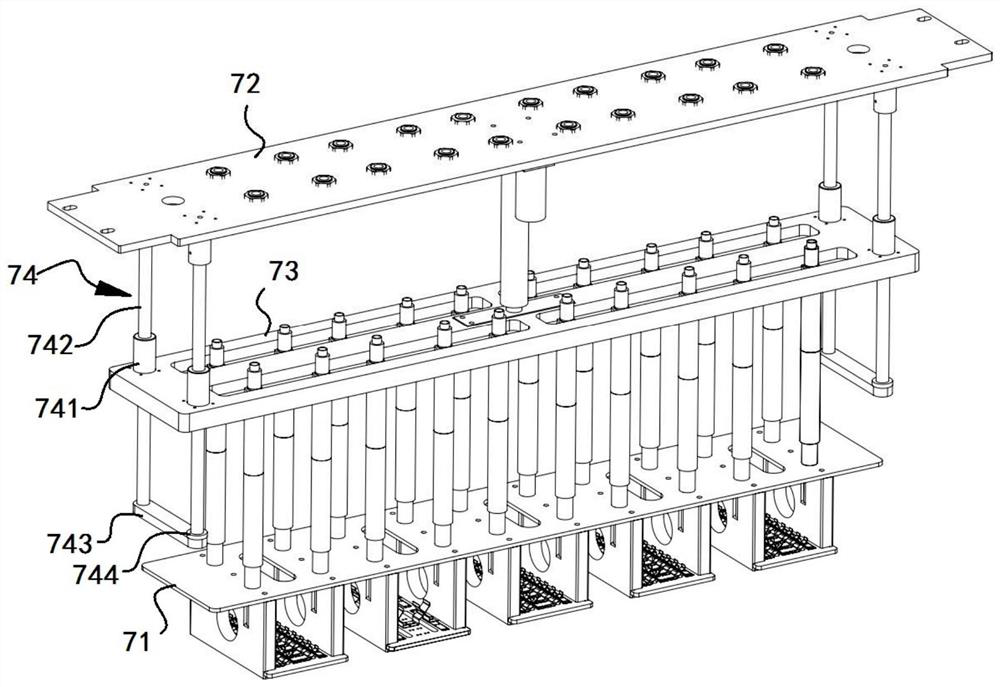

[0040] Such as Figures 10 to 12 As shown, in this embodiment, the high-throughput high-pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com