Vegetable salad and processing technology

A processing technology and vegetable technology, applied in the field of vegetable salad and processing technology, can solve the problems of reducing vegetable nutrition, affecting the appearance, side effects, etc., to achieve the effects of improving the richness of the aroma, improving the crisp taste, and avoiding side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A vegetable salad, the formula comprising: cabbage, lettuce, purple cabbage, bitter chrysanthemum, cherry tomatoes, corn kernels, cucumber, mint leaves, yogurt, carrots, okra and sesame seeds, the parts by weight of each component are respectively: 9-10 parts of cabbage, 9-10 parts of lettuce, 3-5 parts of purple cabbage, 2-3 parts of bitter chrysanthemum, 1-2 parts of cherry tomatoes, 1-2 parts of corn kernels, 1-2 parts cucumber, 0.1-0.2 mint leaves, 2-3 yogurt, 1-2 carrots, 3-5 okra and 0.3-0.5 sesame seeds, wherein the corn kernels are frozen fresh corn grain, the length of okra is 5-6cm.

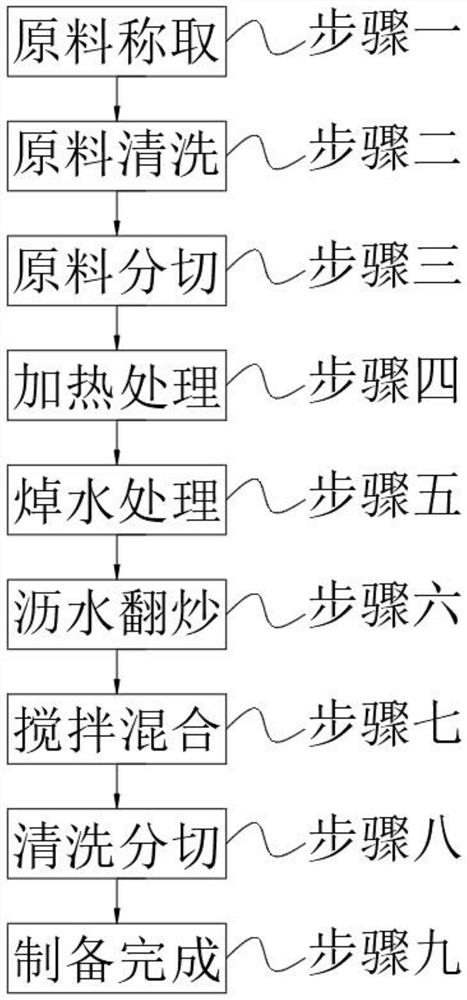

[0027] A processing technology for vegetable salad, comprising the following steps: step 1, weighing raw materials; step 2, cleaning raw materials; step 3, cutting raw materials; step 4, heating treatment; step 5, blanching treatment; Stir fry; Step 7, stir and mix; Step 8, wash and cut; Step 9, preparation is complete;

[0028] Wherein above-mentioned step 1, at first accordin...

Embodiment 2

[0038]A vegetable salad, the formula comprising: cabbage, lettuce, purple cabbage, bitter chrysanthemum, cherry tomatoes, corn kernels, cucumber, mint leaves, yogurt, carrots, okra and sesame seeds, the parts by weight of each component are respectively: 9-10 parts of cabbage, 9-10 parts of lettuce, 3-5 parts of purple cabbage, 2-3 parts of bitter chrysanthemum, 1-2 parts of cherry tomatoes, 1-2 parts of corn kernels, 1-2 parts cucumber, 0.1-0.2 mint leaves, 2-3 yogurt, 1-2 carrots, 3-5 okra and 0.3-0.5 sesame seeds, wherein the corn kernels are frozen fresh corn grain, the length of okra is 5-6cm.

[0039] A processing technology for vegetable salad, comprising the following steps: step 1, weighing raw materials; step 2, cleaning raw materials; step 3, cutting raw materials; step 4, heating treatment; step 5, blanching treatment; Stir fry; Step 7, stir and mix; Step 8, wash and cut; Step 9, preparation is complete;

[0040] Wherein above-mentioned step 1, at first according...

Embodiment 3

[0050] A vegetable salad, the formula comprising: cabbage, lettuce, purple cabbage, bitter chrysanthemum, cherry tomatoes, corn kernels, cucumber, mint leaves, yogurt, carrots, okra and sesame seeds, the parts by weight of each component are respectively: 9-10 parts of cabbage, 9-10 parts of lettuce, 3-5 parts of purple cabbage, 2-3 parts of bitter chrysanthemum, 1-2 parts of cherry tomatoes, 1-2 parts of corn kernels, 1-2 parts cucumber, 0.1-0.2 mint leaves, 2-3 yogurt, 1-2 carrots, 3-5 okra and 0.3-0.5 sesame seeds, wherein the corn kernels are frozen fresh corn grain, the length of okra is 5-6cm.

[0051] A processing technology for vegetable salad, comprising the following steps: step 1, weighing raw materials; step 2, cleaning raw materials; step 3, cutting raw materials; step 4, heating treatment; step 5, blanching treatment; Stir fry; Step 7, stir and mix; Step 8, wash and cut; Step 9, preparation is complete;

[0052] Wherein above-mentioned step 1, at first accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com