Frozen instant halogenated squid and processing method thereof

A processing method and technology of squid, which is applied in the field of frozen ready-to-eat brine squid and its processing, can solve problems such as health hazards, squid product texture, crispness and flavor substance damage, and achieve extended shelf life, protein stability protection, and good appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

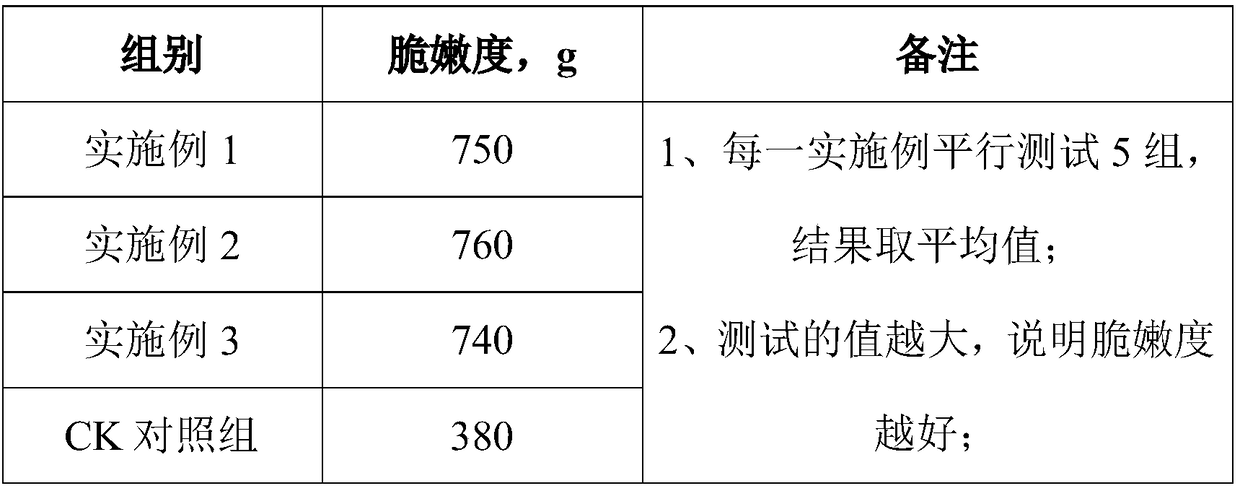

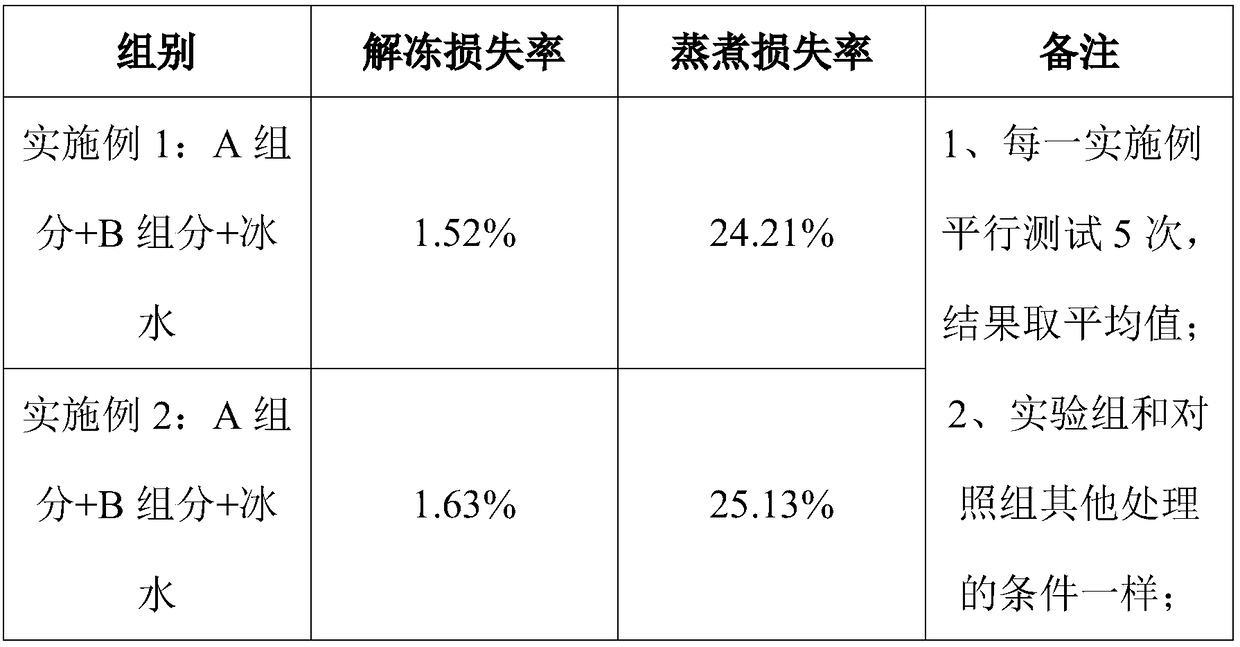

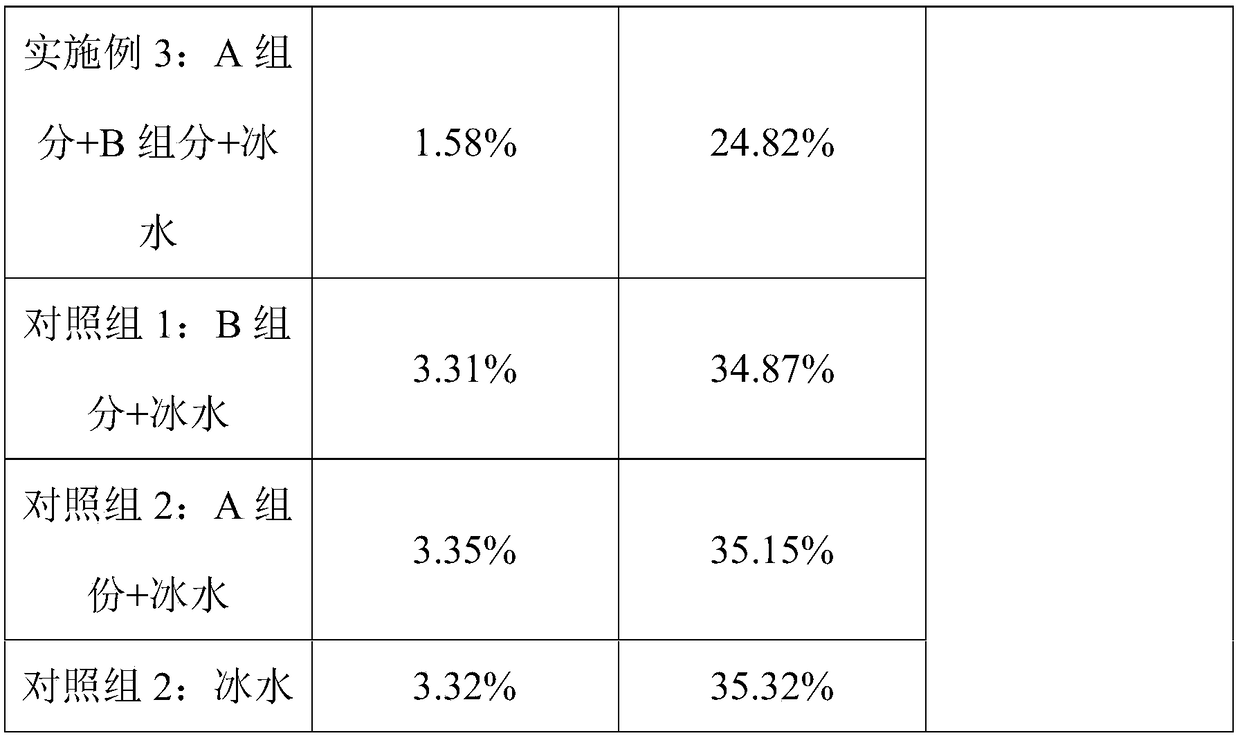

Embodiment 1

[0037] A method for processing frozen instant braised squid, specifically including the following steps:

[0038] S1. After pretreatment, the squid is rinsed clean and soaked; when soaking, mix the A component and the B component uniformly, and the A component includes the following components by weight percentage: sodium carbonate 0.8%, sodium citrate 1.5%, sorbitol 2%, 0.5% trehalose and 1% edible salt. Component A contains sodium carbonate, sodium citrate, sorbitol, trehalose and edible salt. Through the coordinated interaction of batches, the pH of the soaking solution is adjusted to 6.6~ Between 7.0, it can improve the water retention performance of squid and avoid the denaturation of squid protein. The better the water retention capacity of squid, the better the texture and tenderness of the squid. The B component includes the following ingredients by weight percentage: 3% green onion, 3% ginger, 2% cooking wine and 8% beer; B component contains green onions, Ginger and co...

Embodiment 2

[0044] S1. After pretreatment, the squid is rinsed and soaked; when soaking, mix the A component and the B component uniformly. The A component includes the following components by weight percentage: sodium carbonate 2.2%, sodium citrate 5%, sorbitol 4%, trehalose 1.5% and edible salt 1.5%. The A component contains sodium carbonate, sodium citrate, sorbitol, trehalose and edible salt. Through the coordinated interaction of batches, the pH of the soaking solution is adjusted to 6.6~ Between 7.0, it can improve the water retention performance of squid and avoid the denaturation of squid protein. The better the water retention performance of the squid, the better the texture of the squid; the B component includes the following ingredients by weight percentage: 8% green onion, 8% ginger, 4% cooking wine and 12% beer; B component contains green onions, Ginger and cooking wine are mainly used to remove fishy; the mixture of component A and component B is added to 53.8% of ice water, ...

Embodiment 3

[0050] S1. After pretreatment, the squid is rinsed clean and soaked; when soaking, mix the A component and the B component uniformly, and the A component includes the following components by weight percentage: sodium carbonate 1.6%, sodium citrate 3.5%, sorbitol 3%, 1% trehalose and 1.2% edible salt. Component A contains sodium carbonate, sodium citrate, sorbitol, trehalose and edible salt. Through the coordinated interaction of batches, the pH of the soaking solution is adjusted to 6.6~ Between 7.0, it can improve the water retention performance of squid and avoid the denaturation of squid protein. The better the water-retaining performance of squid, the better the texture of squid. The B component includes the following ingredients by weight percentage: containing 5% of spring onion, 5% of ginger, 3% of cooking wine and 10% of beer; component B contains onion, Ginger and cooking wine are mainly used to remove fishy; Add the mixture of component A and component B to 66.7% of i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com