Automatic cutting and grinding device for Chinese herbal medicines

A technology of automatic cutting and grinding device, applied in cocoa, grain processing, chemical instruments and methods, etc., can solve problems such as waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

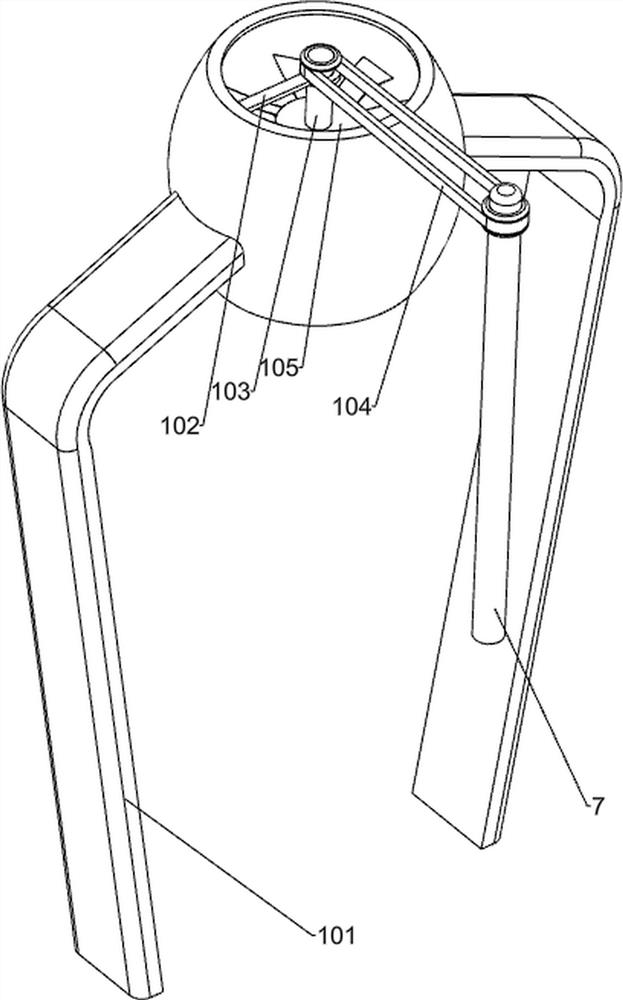

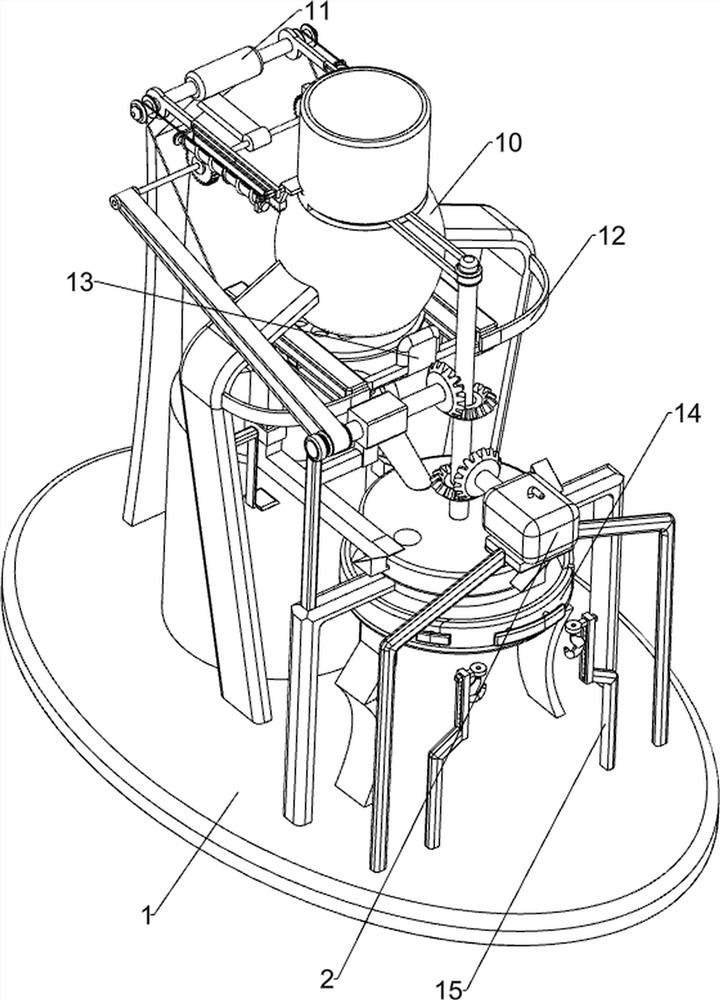

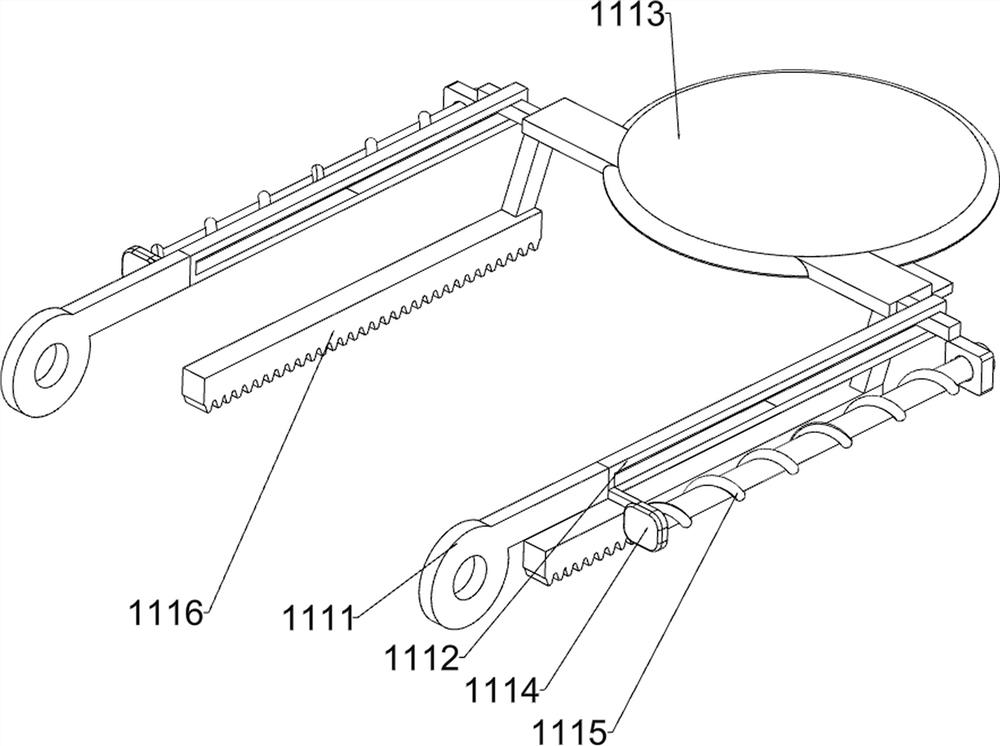

[0029] A Chinese herbal medicine automatic cutting and grinding device, such as Figure 1-7 As shown, it includes a bottom plate 1, a motor 2, a first support column 3, a support plate 4, a first rotating shaft 5, a grinding wheel 6, a second rotating shaft 7, a first object gear 8, a funnel 9, a slicing mechanism 10 and an indirect upper Material mechanism 11, motor 2 is provided on the right side of base plate 1, two first support columns 3 are provided on the right side of base plate 1, support plate 4 is connected between the first support columns 3, and the middle part of support plate 4 is rotatably connected with a first Rotating shaft 5, the top of the first rotating shaft 5 is provided with a grinding wheel 6, the middle of the grinding wheel 6 is connected with a second rotating shaft 7, the lower side of the second rotating shaft 7 and the output shaft of the motor 2 are connected with a first object gear 8, the first object gear 8 Mesh with each other, the bottom p...

Embodiment 2

[0034] On the basis of Example 1, such as Figure 8-11 As shown, a sieve mechanism 12 is also included, and the sieve mechanism 12 includes an eighth support frame 121, a third slide rail 122, a sieve plate 123, a second spring 124, a limit frame 125, a ninth support column 126, The first wedge-shaped block 127 and the second wedge-shaped block 128, the right side of the second support column 101 top are all provided with the eighth support frame 121, the left side of the eighth support frame 121 is all provided with the third slide rail 122, the third slide rail 122 A sieve plate 123 is slidably connected between them, a limit frame 125 is provided on the right side of the third slide rail 122, a second spring 124 is provided between the left side of the limit frame 125 and the sieve plate 123, and the first spring 124 on the front side The ninth support column 126 is arranged on the inner side of the upper part of the second support column 101, the first wedge-shaped block 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com