Cage type water-cooling and mist-cooling double-circulation cooling device for garbage can and garbage can

A technology of cooling device and trash can, applied in trash can, garbage collection, application, etc., can solve problems such as poor convenience, and achieve the effect of convenient garbage disposal, good market prospect, and high adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

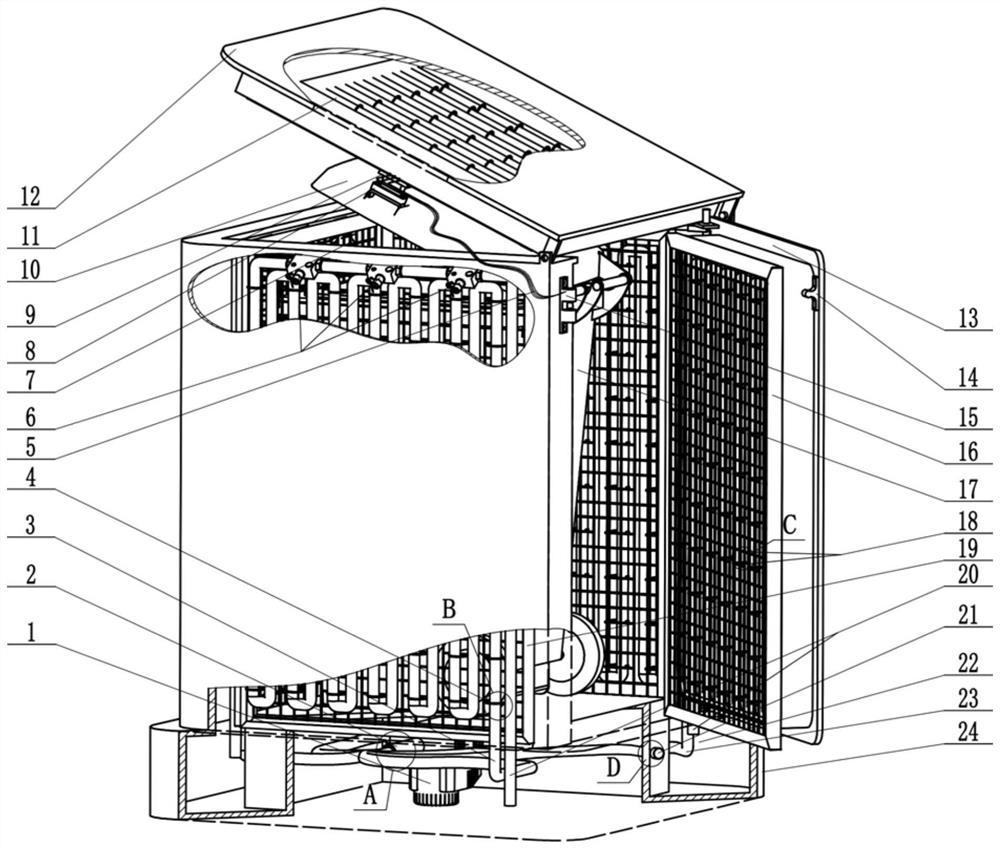

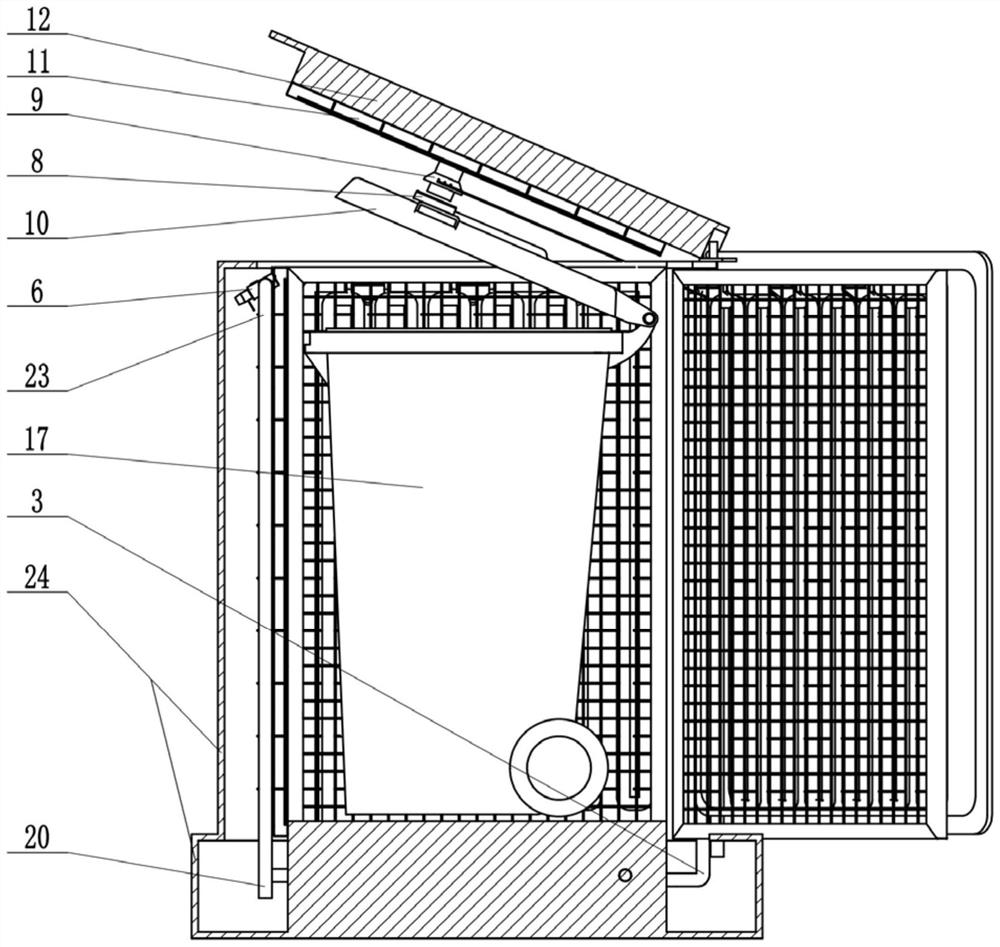

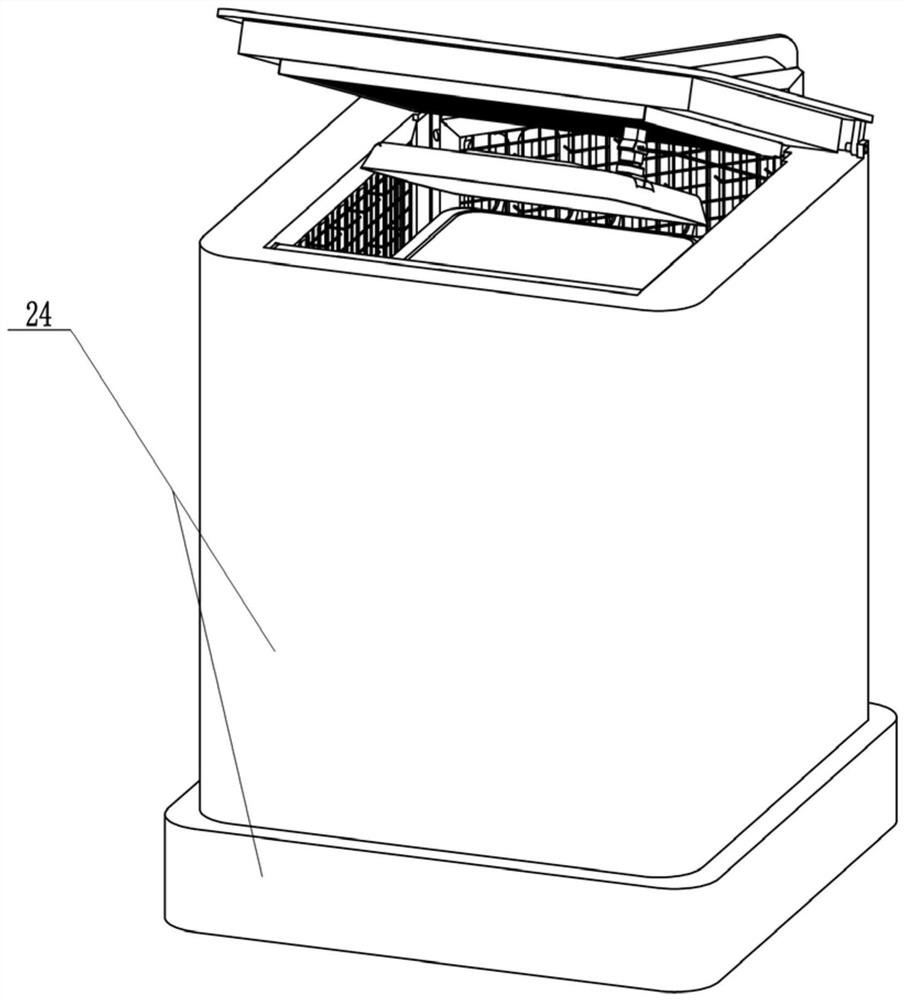

[0029] A cage-type water-cooled mist-cooled double-cycle cooling device for garbage cans, such as figure 1 , 2 Shown, comprise top cover 12, tail cover 13, box cover 24, cooling water circulation device and linkage type opening and closing device.

[0030] The top cover 12 is arranged at the top opening of the case cover 24, and one side of the top cover 12 is connected with the case cover 24 through a horizontal fixed axis rotation, so that the top cover 12 can be rotated and opened around the fixed axis. Tail cover 13 is arranged on the back opening of box cover 24, and one side of tail cover 13 and box cover 24 are connected by vertical fixed axis rotation, so that tail cover 13 rotates and opens and closes around fixed axis. A cavity is formed between the case cover 24 and the top cover 12, the tail cover 13, the cooling water circulation device and the garbage can are all arranged in the cavity, and the bottom 1 / 5 height of the case cover 24 is buried underground, as i...

Embodiment 2

[0041] A trash can matched with a cage-type water-cooled mist-cooled double-cycle cooling device, which is placed inside the cage-type water-cooled mist-cooled double-cycle cooling device for a trash can, including a trash can body 17 and a trash can cover 10, and a trash can cover 10 One side of the trash can body 17 is connected by horizontal fixed axis rotation, and the outer surface of the trash can cover 10 is equipped with a magnetic switch seat 8, and the magnetic switch seat 8 is connected with the magnetic switch mounted on the cooling wall 11 on the top surface. The positions of the caps 9 are corresponding and can be attracted to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com