Full-automatic traffic cone collecting engineering vehicle

A technology for traffic cones and engineering vehicles, which is applied in the field of fully automatic traffic cone collection engineering vehicles, can solve the problems of difficult promotion, hidden dangers of operation safety, and high maintenance and repair costs, so as to improve work efficiency and construction safety, and reduce driving. Technical requirements, effects of improving efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below according to the accompanying drawings and embodiments.

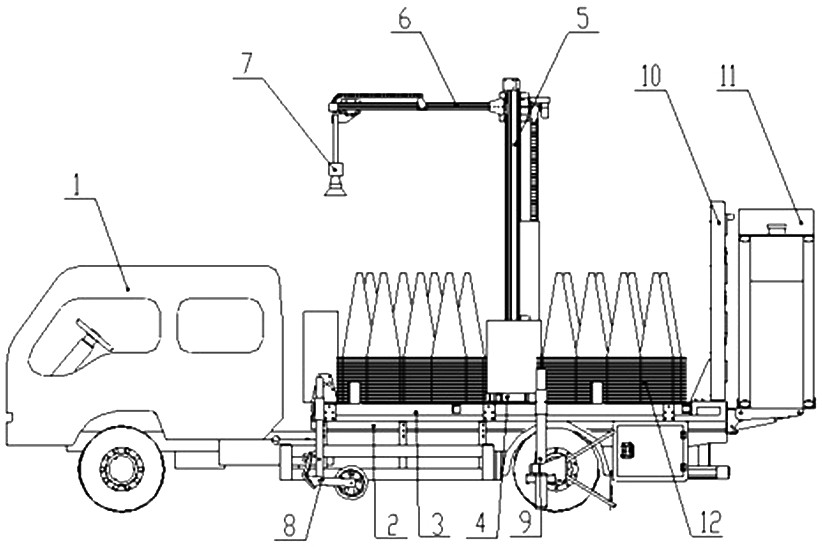

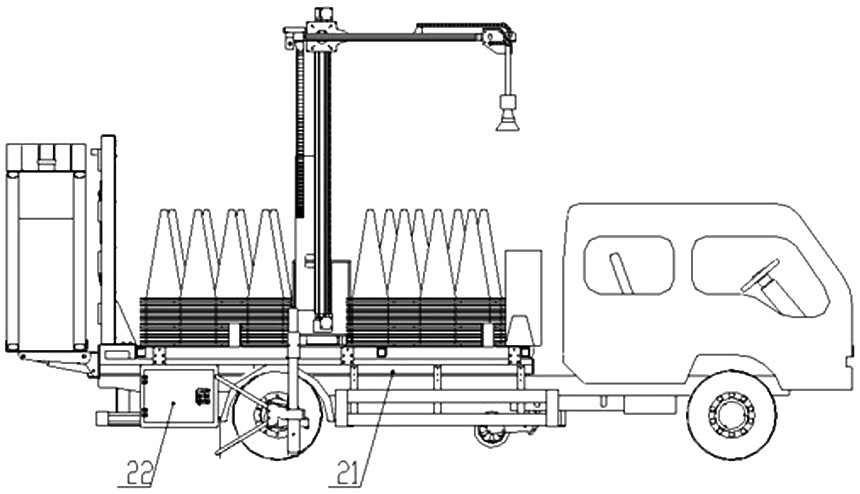

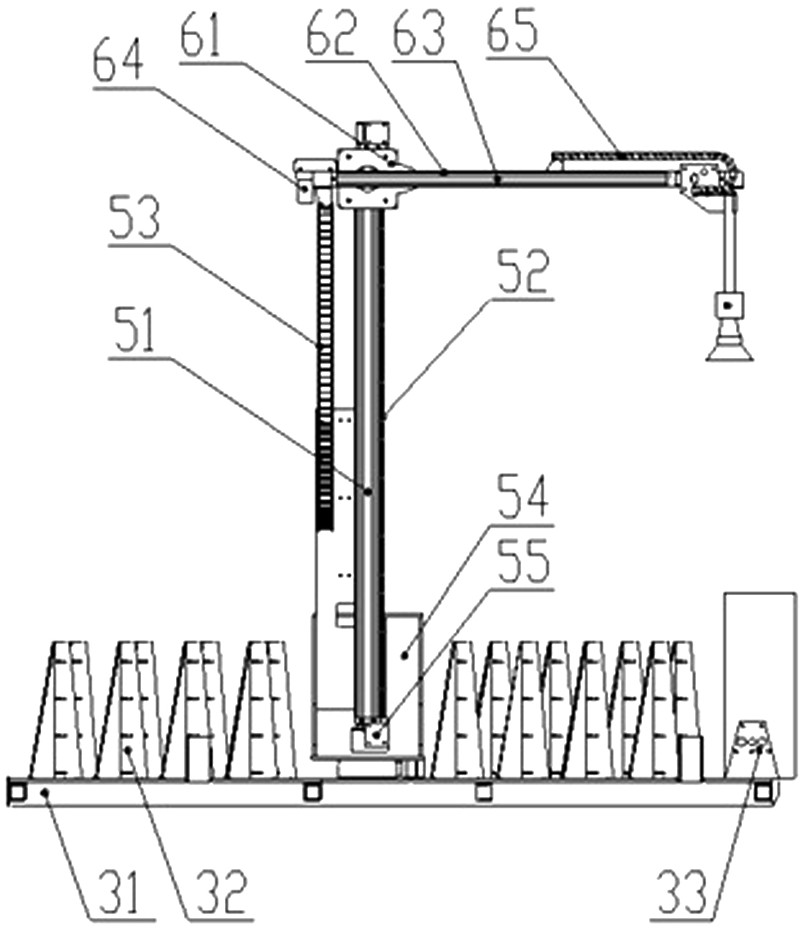

[0031] Such as Figure 1 to Figure 3As shown, a fully automatic traffic cone collection engineering vehicle includes a chassis 1, a frame platform assembly 2, an upper loading platform assembly 3, a slewing mechanism 4, a column assembly 5, a cantilever assembly 6, Grab assembly 7 and guide positioning device 9. Wherein the chassis 1 is a second-class truck chassis, single row and double row seats can be selected, and the double row seat 4 * 2 car chassis is preferred in this application. The frame platform assembly 2 includes a frame platform 21 and a toolbox 22. The frame platform 21 is a structural component welded by plates and pipes, and serves as a carrier for upper parts. The frame platform 21 is fixed to the chassis 1 girder by bolts Above: the toolbox 22 is fixed on both sides of the rear part of the vehicle frame platform 21 by bolts, and the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com