Mold spraying concrete construction method and wet spraying trolley

A sprayed concrete and construction method technology, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve problems such as long construction time, affecting construction quality, and prone to honeycomb pitting, so as to improve construction efficiency and shorten construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

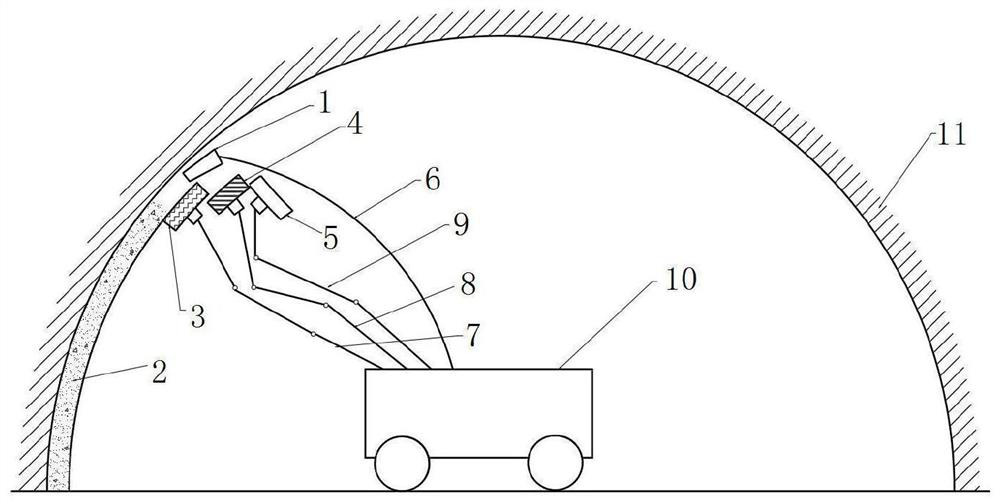

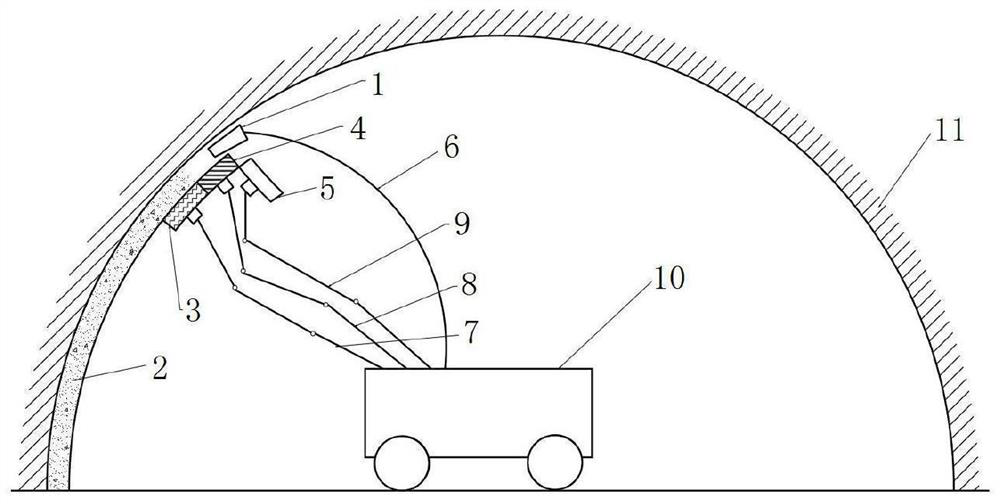

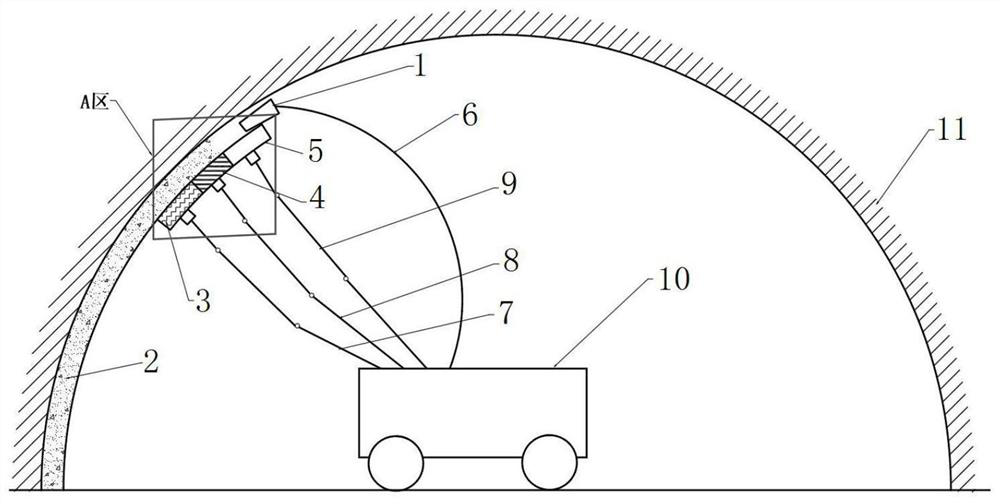

Embodiment 1

[0039] A sprayed concrete construction method, using M block templates for support construction, that is, constructing a concrete support layer 2, wherein the initial setting time of concrete is equal to the spraying construction time of M-1 block templates, the construction method of this embodiment is selected by selecting A formwork with a suitable span (that is, a suitable formwork width, where the widths of the M formworks are equal), so that when the injection of the Mth formwork cavity is completed, the concrete in the first formwork cavity has solidified to a certain strength, so The formwork can be moved continuously to construct the next mold cavity, and the whole spraying process does not need to waste time waiting for the concrete in the mold cavity to solidify, which specifically includes the following steps:

[0040] Step S1: The wet spraying trolley travels to the tunnel section to be sprayed, and the nozzle 1 of the wet spraying trolley sprays the mold cavities ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com