Internal-tangent external-resistance type barrel-shaped structural plane shearing instrument combined with 3D printing technology

A 3D printing and structural surface technology, applied in the direction of applying stable shear force to test the strength of materials, instruments, scientific instruments, etc., can solve the problems of test data correction, difficult residual strength, and shear area reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

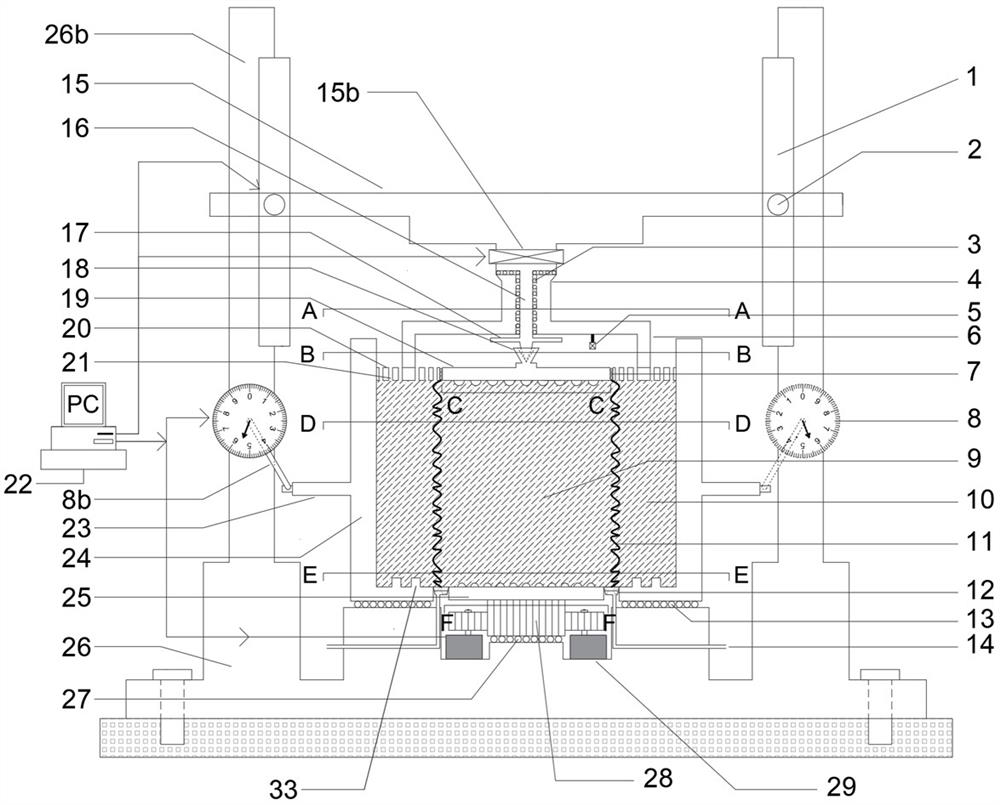

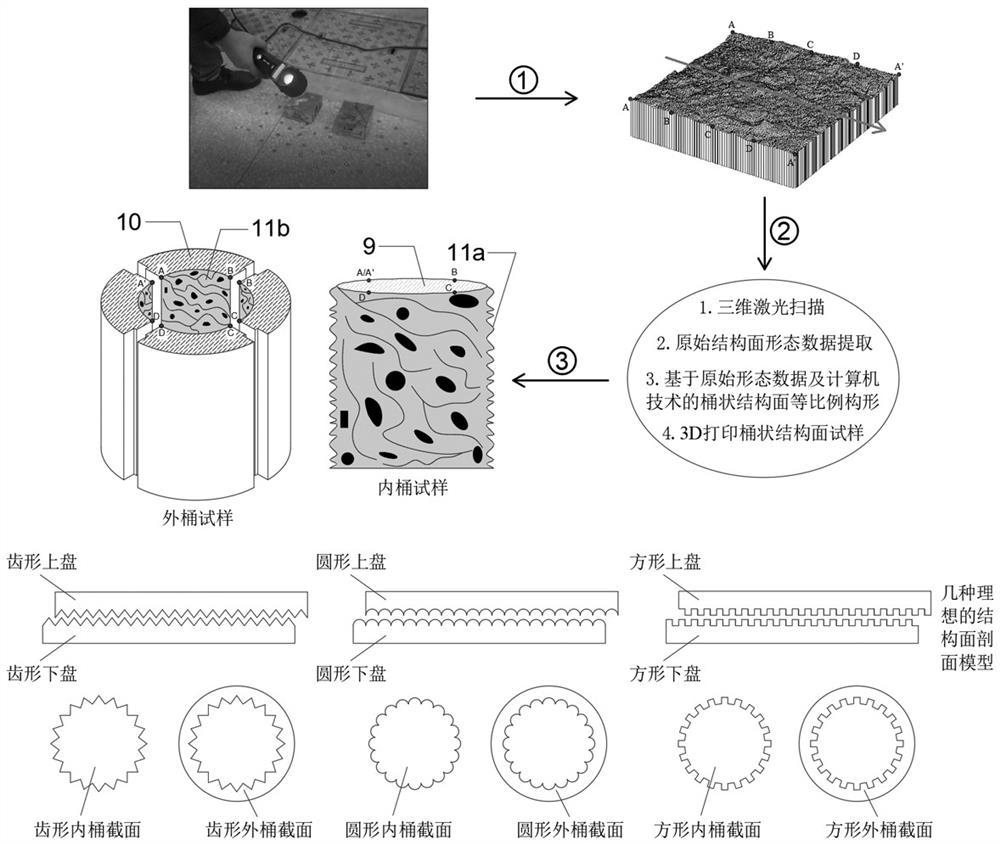

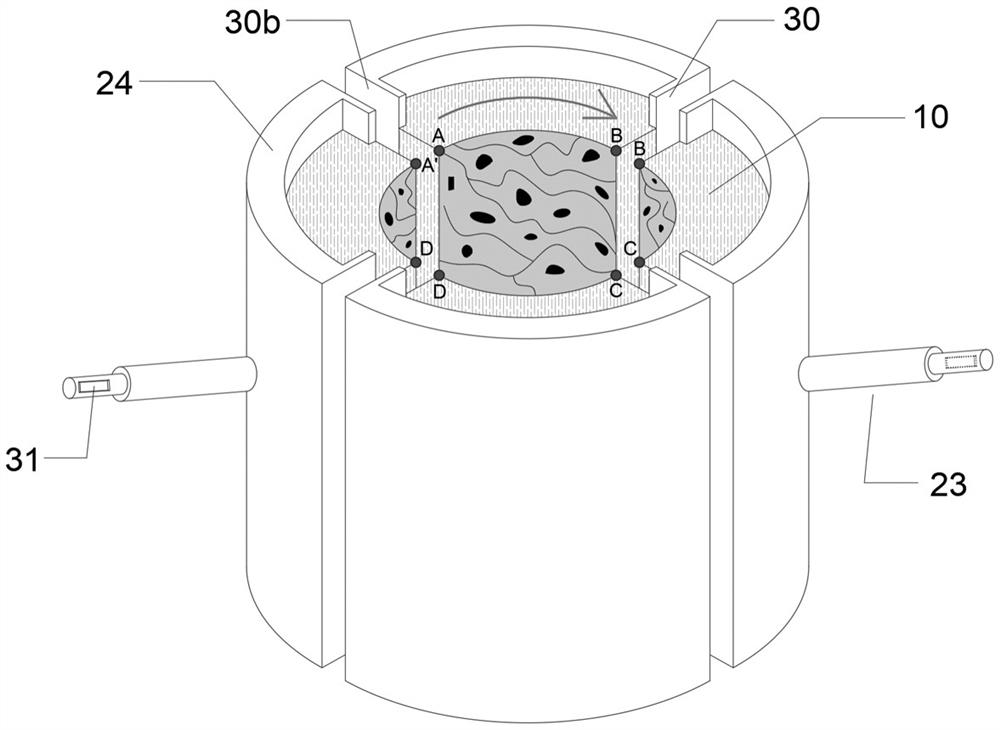

[0043]This embodiment is a barrel-shaped structural surface shearing instrument with internal cutting and external resistance, which mainly includes a frame 26, a shear box, an axial pressure mechanism I, an axial pressure mechanism II, a rotary drive mechanism, and a shear monitoring mechanism And the computer 22 etc., are used for carrying out the shearing mechanics test by using the outside structure surface 11a of the barrel-shaped inner sample and the inside structure surface 11b of the ring-shaped outer sample.

[0044] In order to facilitate the precise alignment and assembly of the rock mass structural surface 11 between the barrel-shaped inner sample 9 and the ring-shaped outer sample 10 during the test, it is avoided that the ring-shaped outer sample 10 is directly placed on the barrel-shaped inner sample 9 and other rough surfaces. The operation mode can reduce the damage to the original shape of the structural surface caused by the bonding process of the inner and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com