An ultrasonic inspection device for nuclear reactor pressure vessel joint intersection surface

A pressure vessel, ultrasonic inspection technology, used in nuclear reactor monitoring, reactors, nuclear engineering, etc., can solve the problem of inability to use a fixed motion trajectory scanning method, and achieve the effect of reduced external size, constant size, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

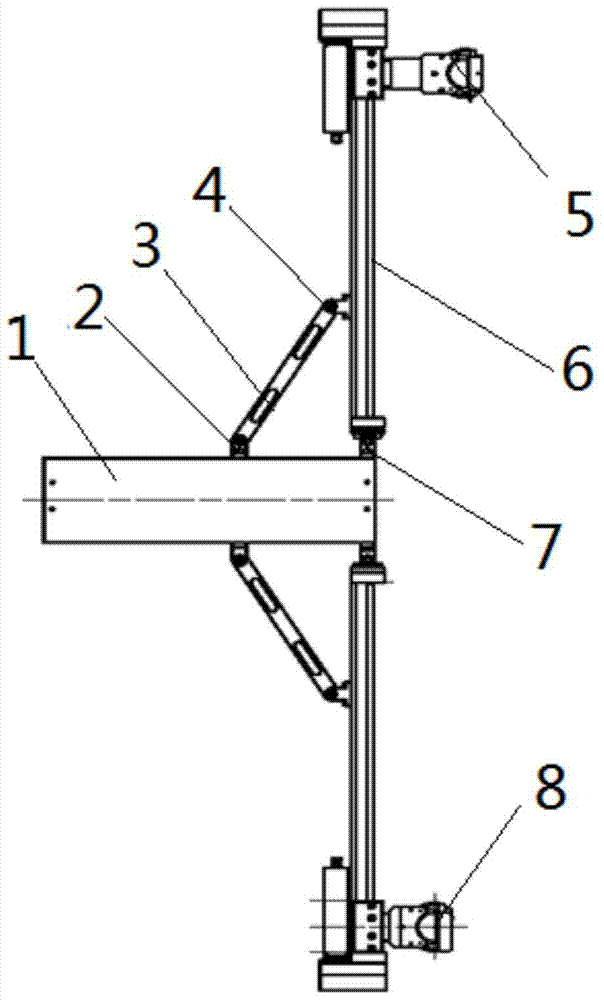

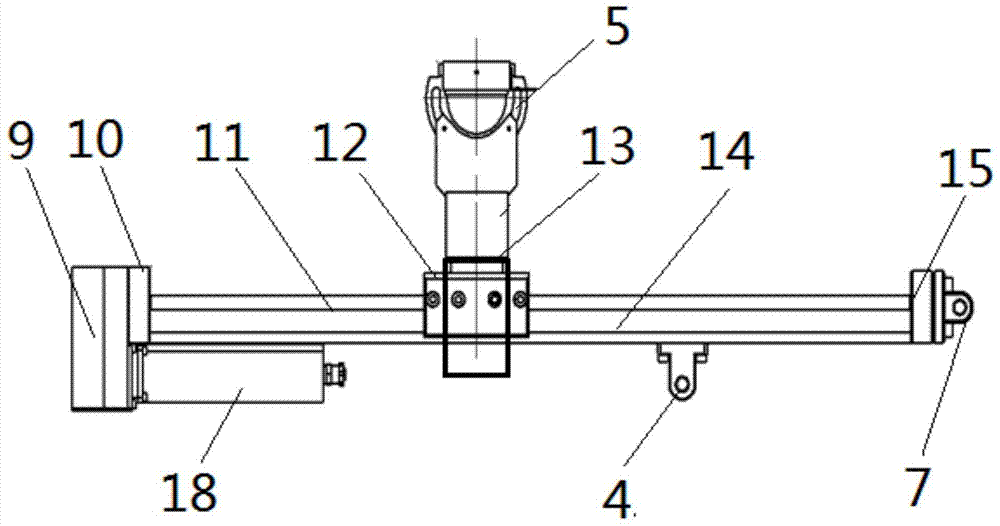

[0019] Such as figure 1 , figure 2 As shown, an ultrasonic inspection device for the junction surface of nuclear reactor pressure vessel includes a driving cylinder 1, a connecting rod 3, a retractable probe holder 5, a scanning arm 6 and a fixed probe holder 8, wherein, The lower end of the driving cylinder part 1 is movably connected with the ends of the two symmetrically distributed scanning arms 6 through the hinge C7, the driving part in the middle part of the driving cylinder part 1 is movably connected with one end of the connecting rod 3 through the hinge A2, and the other end of the connecting rod 3 is through the hinge B4 It is movably connected with the scanning arm 6; the drive cylinder 1 drives the two symmetrically distributed scanning arms 6 to shrink or expand through the connecting rod 3; Box 9, wherein a motor 18 and a reduction box 9 are fixedly installed on the end of the guide rail 14 away from the hinge C7, the lead screw 11 is installed on the guide ra...

Embodiment 2

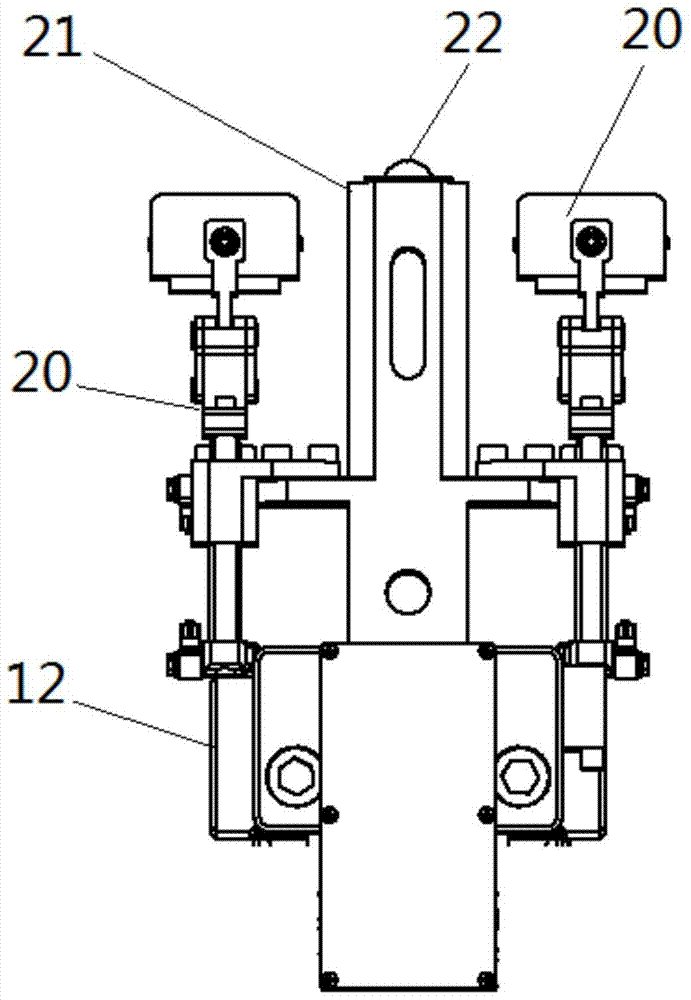

[0022] Such as image 3 As shown, an ultrasonic inspection device for a nuclear reactor pressure vessel joint intersection surface includes a driving cylinder 1, a connecting rod 3, a scanning arm 6, and a probe holder with a support rod structure, wherein the lower end of the driving cylinder 1 passes through the hinge C7 is movably connected with the ends of two symmetrically distributed scanning arms 6, the driving part in the middle of the driving cylinder part 1 is movably connected with one end of the connecting rod 3 through the hinge A2, and the other end of the connecting rod 3 is movably connected with the scanning arm 6 through the hinge B4 ; The drive cylinder 1 drives two symmetrically distributed scanning arms 6 to contract or expand through the connecting rod 3; 14 One end away from the hinge C7 is fixedly installed with a motor 18 and a reduction box 9. The screw 11 is installed on the guide rail 14 in parallel with the bearing seat B15 through the bearing seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com