Automatic assembling mechanism for bullet and pull rope

An assembly mechanism and bullet technology, applied in the field of fitness pull rope, can solve the problems of fast replacement frequency, short service life of parts, and long rest time, so as to reduce physical burden and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

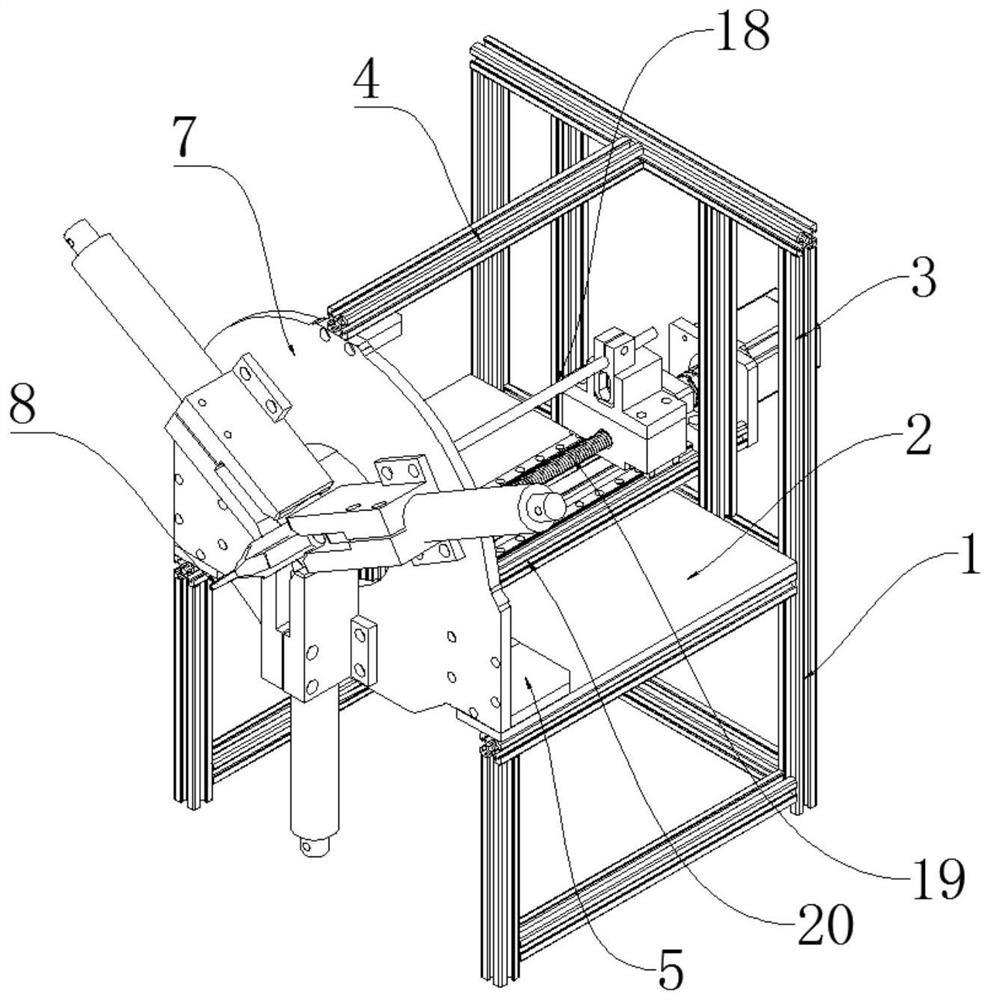

[0037] In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other accompanying drawings based on these drawings and obtain other implementations.

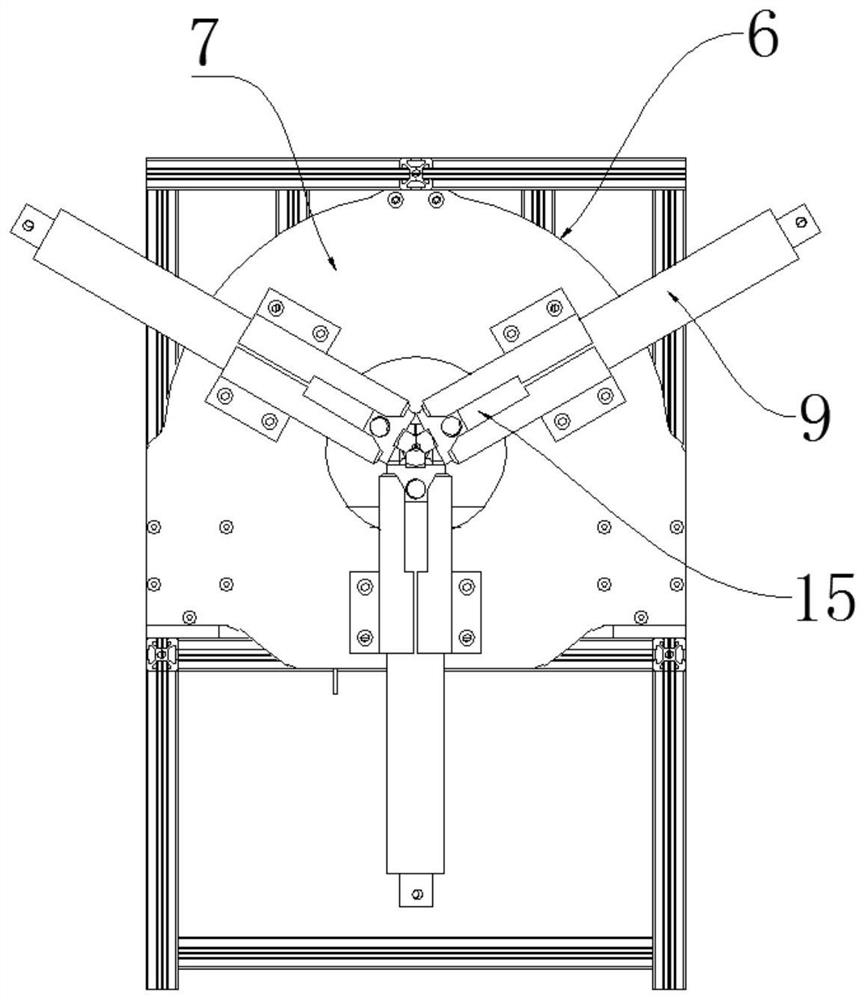

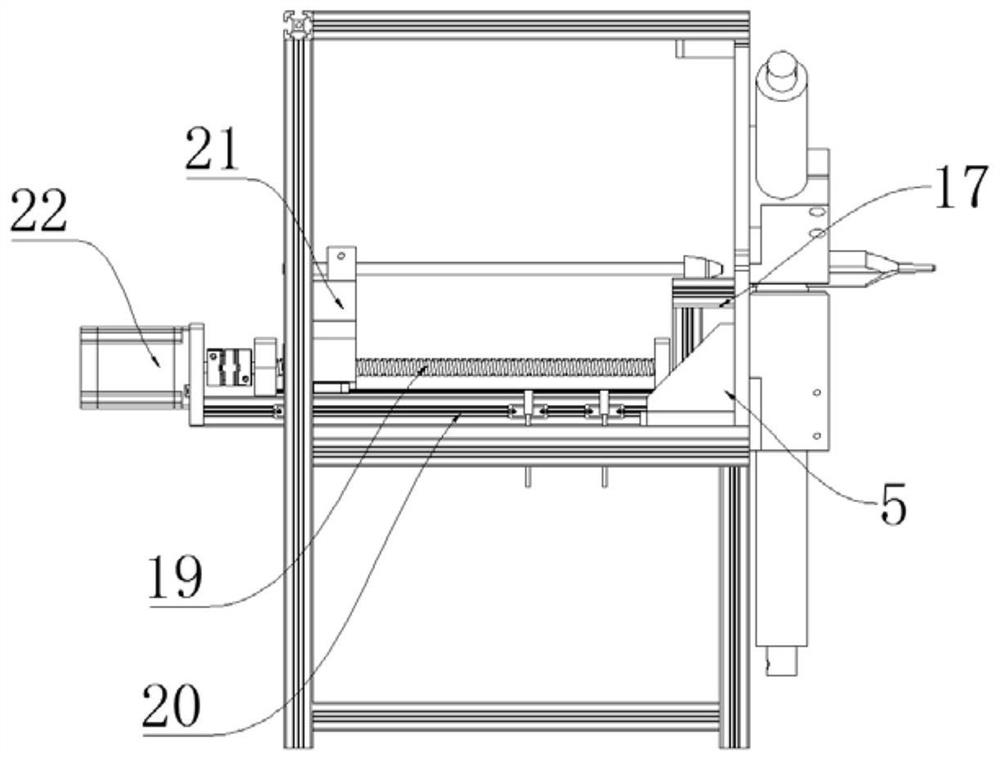

[0038] Such as Figure 1-16 Shown, a kind of automatic assembly mechanism of bullet head and tension rope, comprises:

[0039] The bracket, the bracket includes a support rod 1 and a work surface 2 fixed on the support rod, wherein the upper end of the support rod on the right side of the work surface protrudes above the work surface to form an extension section 3, and the extension section is fixed with a cross bar 4, Both sides of the left end of the worktop are fixedly equippe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap