Packaging paper pressing assembly

A technology of assembly and paper pressing, applied in the field of packaging machinery, can solve problems such as difficult to ensure uniformity of folds, tearing of packaging paper, etc., and achieve the effect of ingenious design, simple action and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

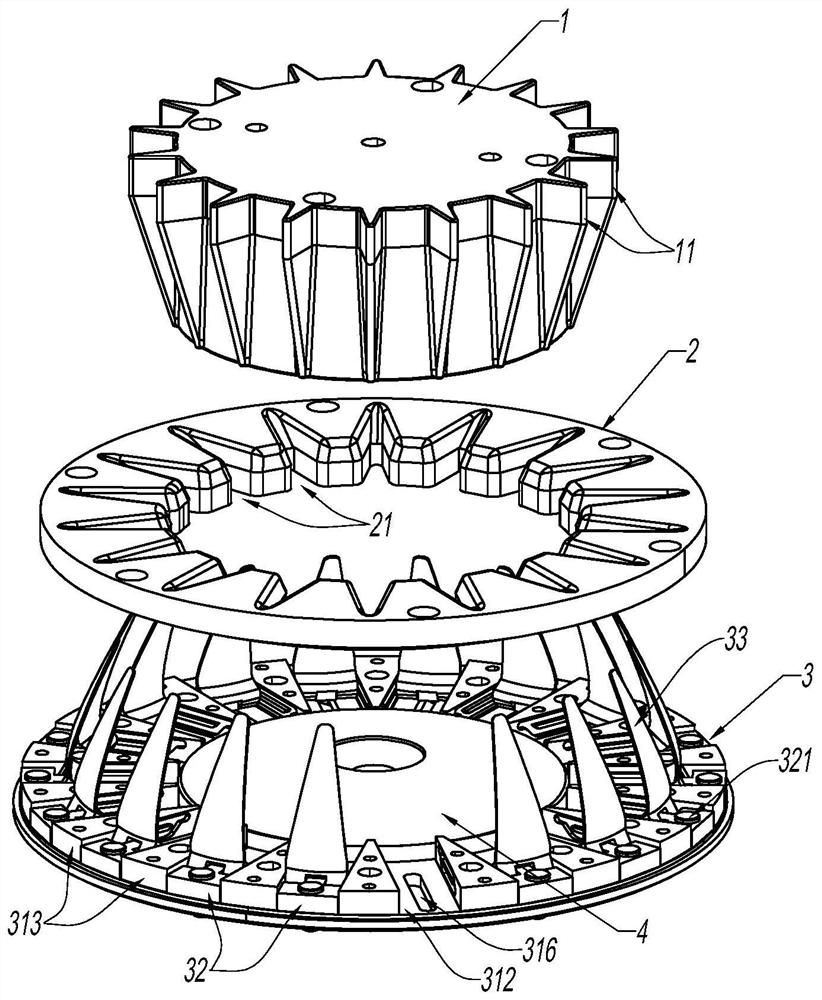

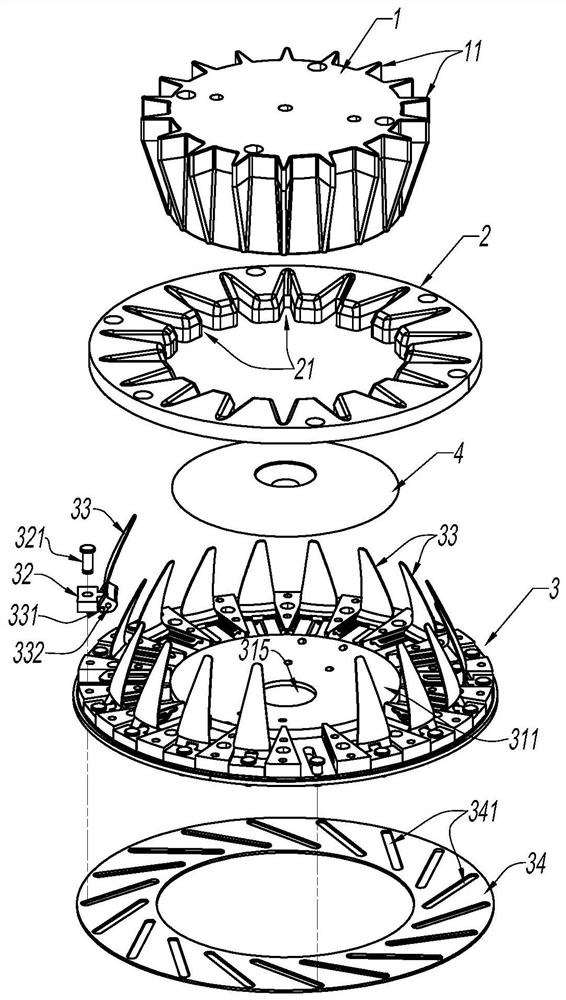

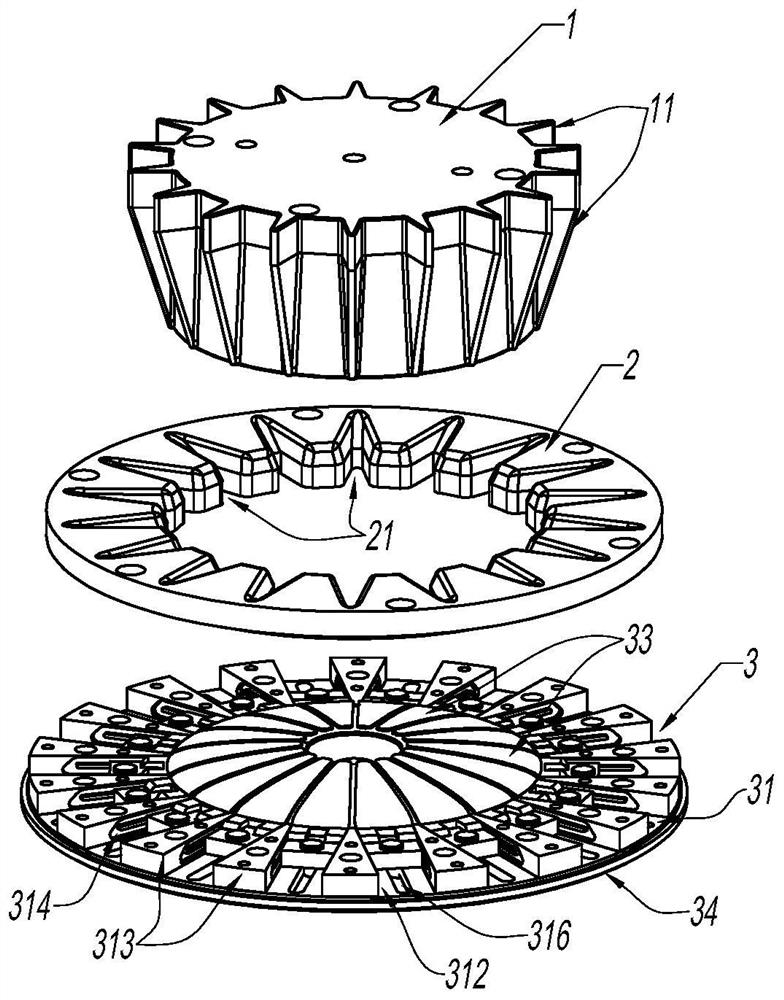

[0031] refer to Figure 1 to Figure 4 , packaging paper pressing assembly, including molding head 1, paper guide die 2 and paper pressing mechanism 3; molding head 1 is located directly above paper guide die 2, and is driven by a power cylinder such as an oil cylinder or an air cylinder to move up and down to complete the paper pressing action. ; The paper guide mold 2 is generally fixed on the working surface, and can receive articles with wrapping paper, such as tea cakes 4, delivered from an automatic feeding belt or a manipulator.

[0032] The paper guide mold 2 has a sheet-like structure, and a plurality of concave-convex grooves 21 are arrayed on the inner circumference; convex teeth 11 corresponding to the number of concave-convex grooves 21 are arrayed on the outer circumference of the molding head 1, and there is a gap between the convex teeth 11 and the concave-convex grooves 21 , that is, the thickness of the paper can be accommodated; the molding head 1 moves up an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com