Leakage-proof testing device for heating and ventilation pipeline

A test device and pipeline technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum, can solve problems such as underpressure, pipeline overpressure, unsatisfactory test results, etc., achieve uniform mixing, avoid manual closing, The effect of improving the service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

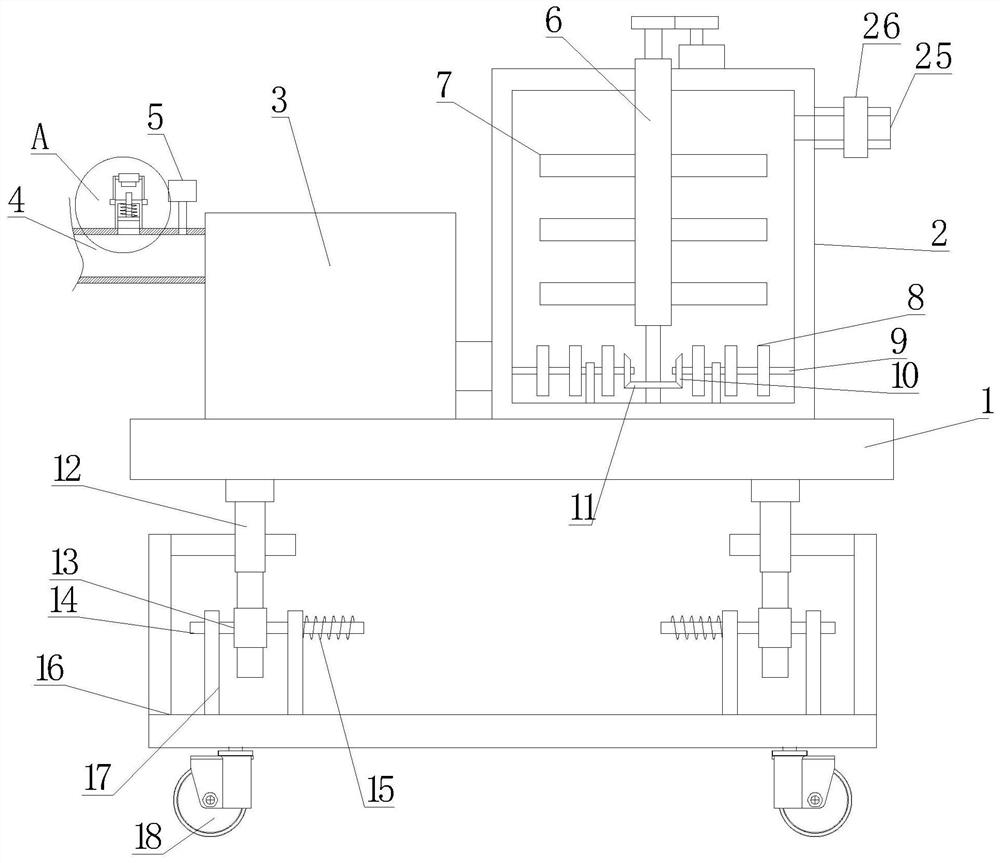

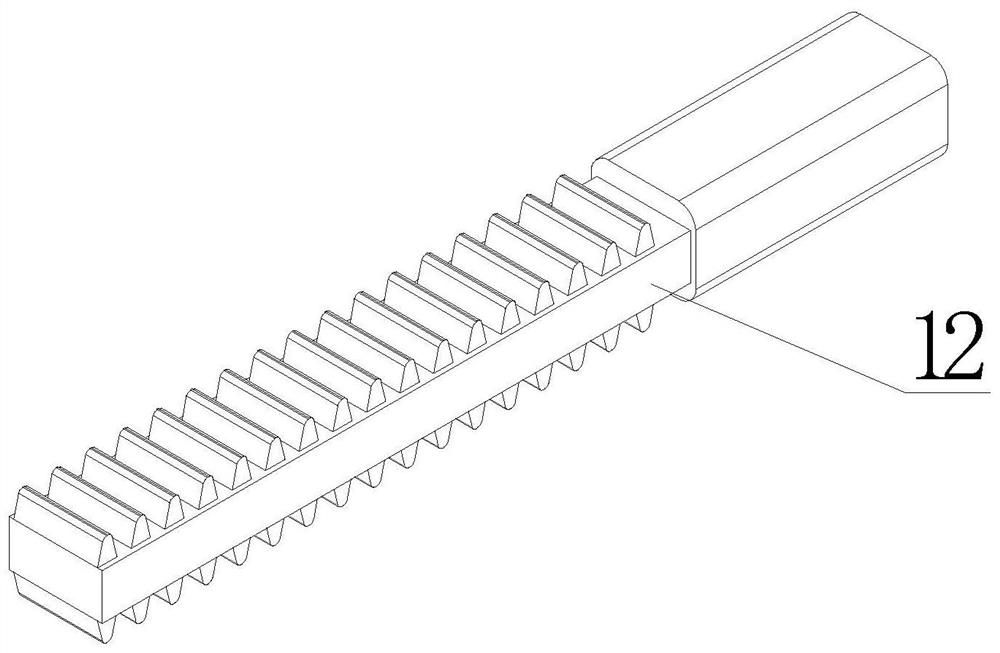

[0024] see Figure 1~3 , in Embodiment 1 of the present invention, it is a structural diagram of a leak-proof testing device for heating and ventilation pipes provided by the embodiment of the present invention, including: a mounting base 1, and a pressure pump 3 and a liquid storage device are arranged on the mounting base 1 In the tank 2, the pressure pump 3 is provided with a first stirring part and a second stirring part inside, and the stirring directions of the first stirring part and the second stirring part are different;

[0025] The input end of the pressure pump 3 communicates with the interior of the liquid storage tank 2 through a pipeline, and the liquid storage tank 2 is used to store water containing cleaning fluid, so that the pipeline can be cleaned during the test process.

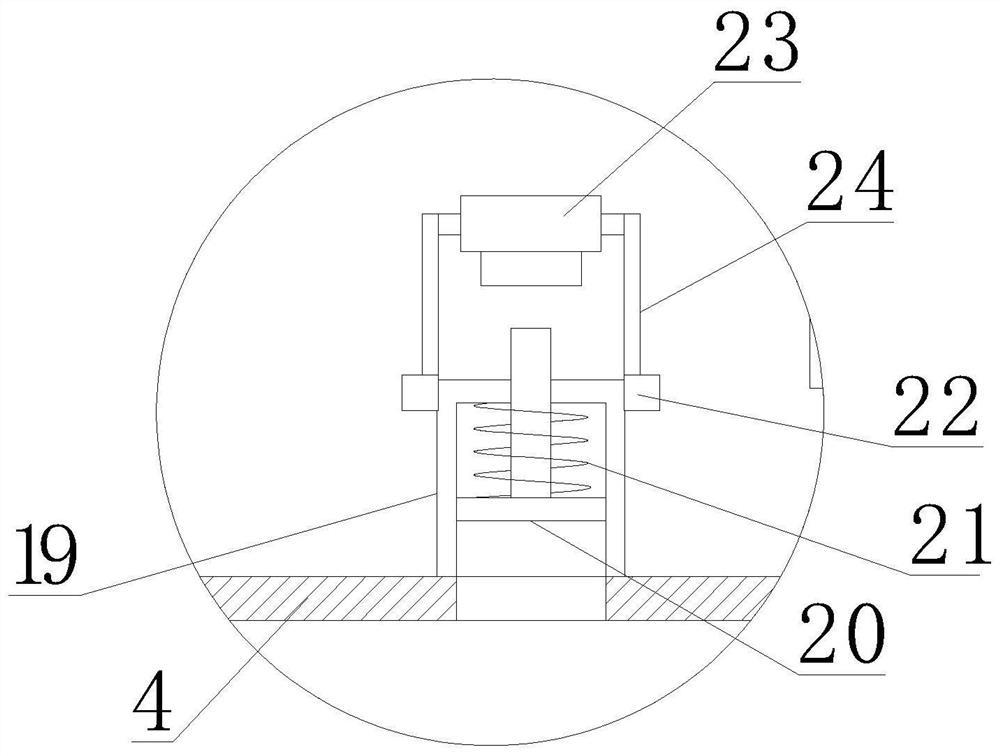

[0026] The pressure supply pump 3 is provided with an output pipe 4, and the output pipe 4 is provided with a voltage stabilizing member 19. The inside of the voltage stabilizing member ...

Embodiment 2

[0031] see Figure 1~3 , The main difference between Embodiment 2 and Embodiment 1 is that the height of the position switch 23 is adjustable, so that it is convenient to meet the requirements of different test pressures.

[0032] Specifically, the outer side of the position switch 23 is connected with a connecting piece 24, and the connecting piece 24 is connected to the adjusting sleeve 22, and the height of the adjusting sleeve 22 is installed on the voltage stabilizing piece 19, so that when the height needs to be adjusted , adjust the position of the adjusting sleeve 22 on the pressure stabilizing member 19 to adjust the height of the position switch 23 , and then realize the closing of the pressure pump 3 at different pressures.

[0033] The adjusting sleeve 22 is mounted on the outside of the voltage stabilizing member 19 through threads, and the connecting member 24 is rotatably mounted on the adjusting sleeve 22 , so that the position switch 23 is prevented from rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com