Visual hot compress glasses lens structure

A spectacle lens and hot compress technology, which is applied in the field of visible hot compress spectacle lens structure, can solve problems such as poor effect, affecting life and work, and being unable to do other things, and achieves the effects of strong toughness, high moisture content, and increased safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0036] The embodiments of the present invention will be described below according to the overall structure of the present invention.

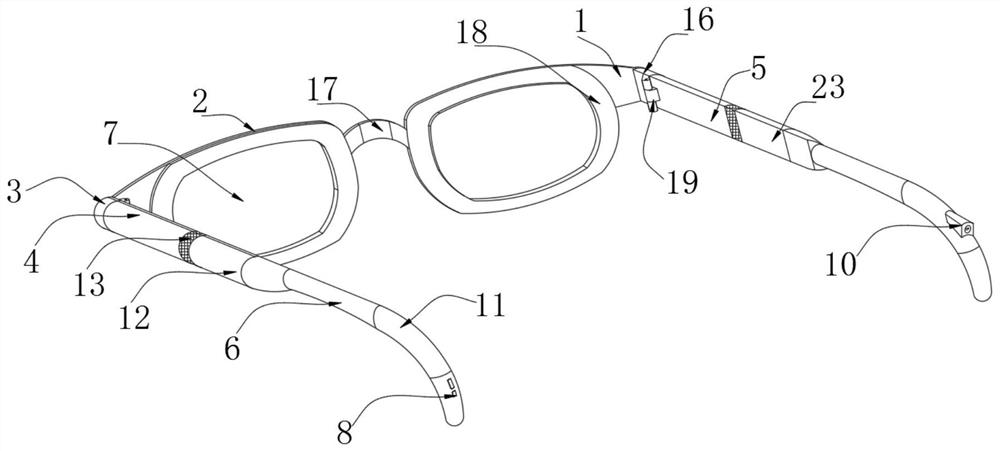

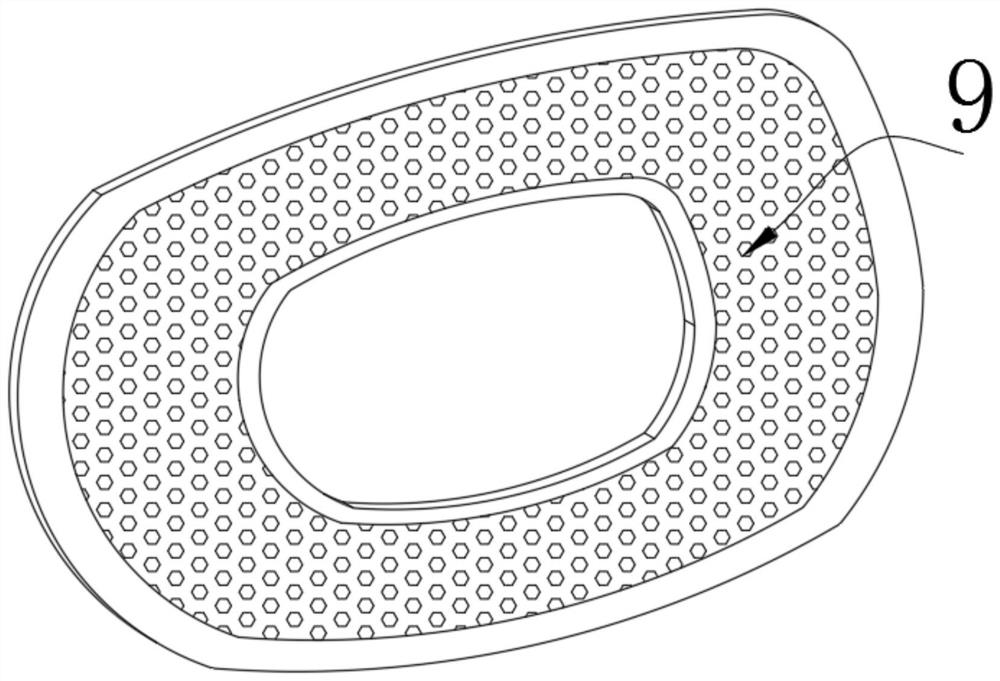

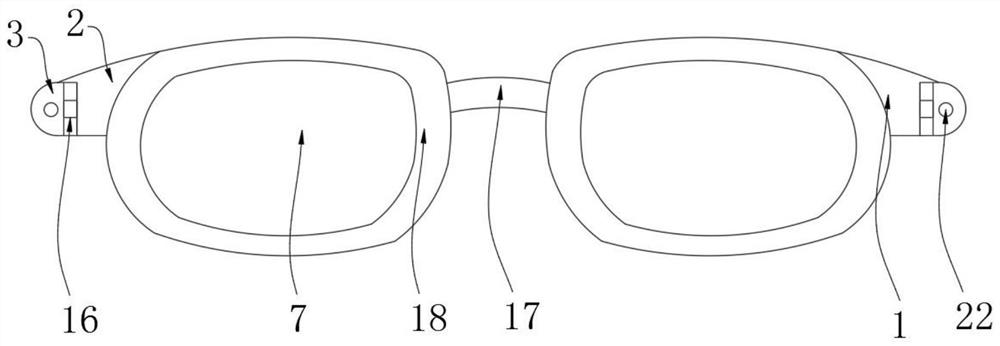

[0037] A kind of visual heat compress spectacle lens structure, such as Figure 1-3 As shown, it includes a right frame 1 and a moisturizing film 9 with holes. One side of the right frame 1 is connected with a left frame 2 through a nose bridge 17. A lens 7 is installed on the inside of the left frame 2, and a film frame 18 is arranged on one side of the left frame 2. , one side of the left mirror frame 2 is provided with a connecting block 3, the connecting block 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com