Silicone oil-in-water cosmetic and preparation method thereof

A cosmetic and oil-in-water technology, which is applied in the field of silicone oil-in-water cosmetics and its preparation, can solve the problems of poor covering effect, low powder content, dryness and the like, and achieves excellent covering effect, long-lasting makeup, and improved affinity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

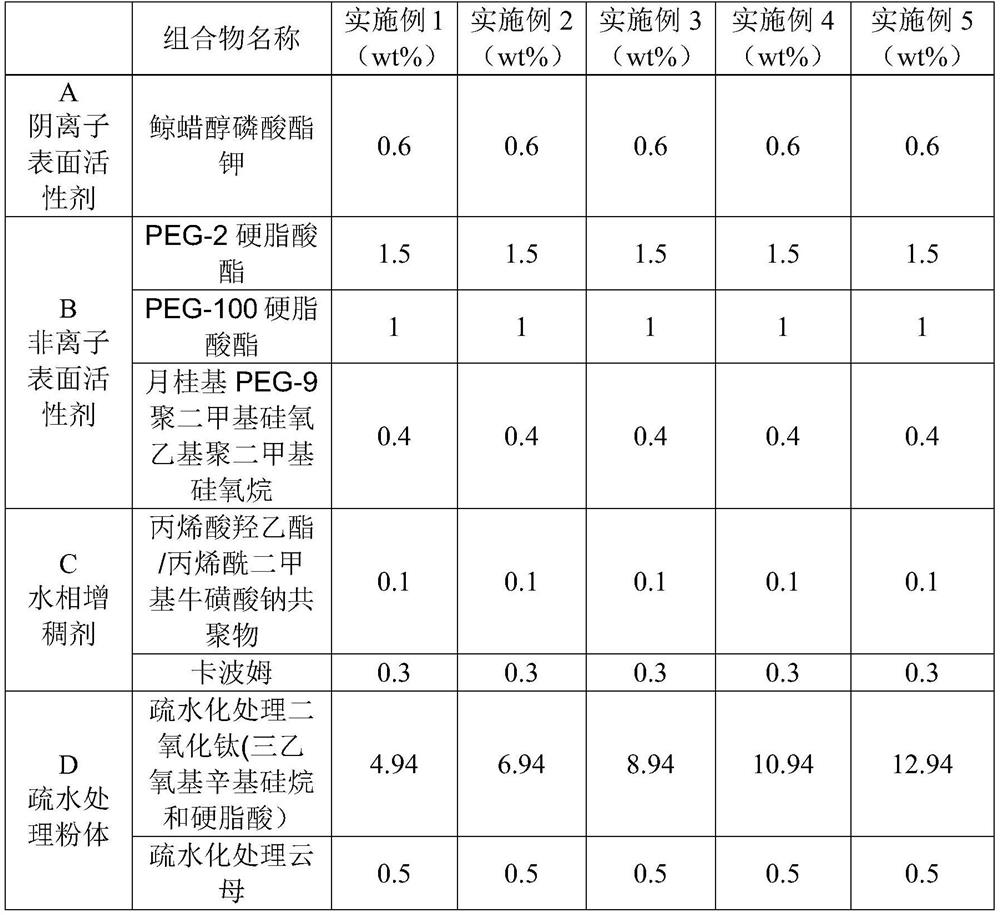

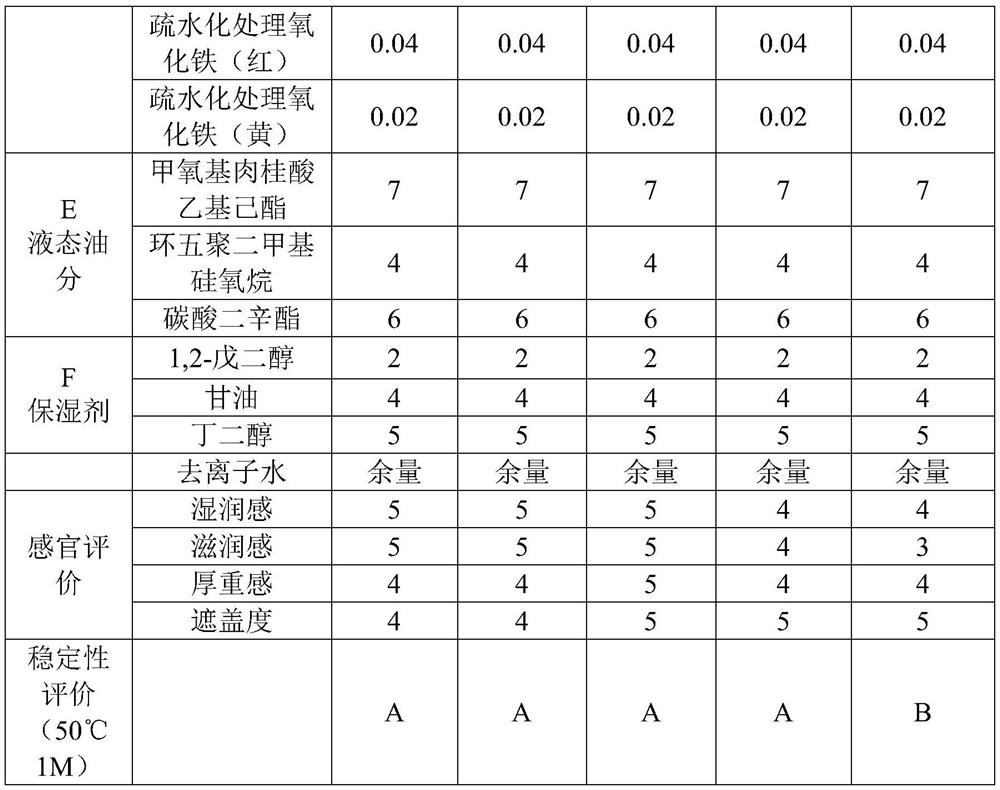

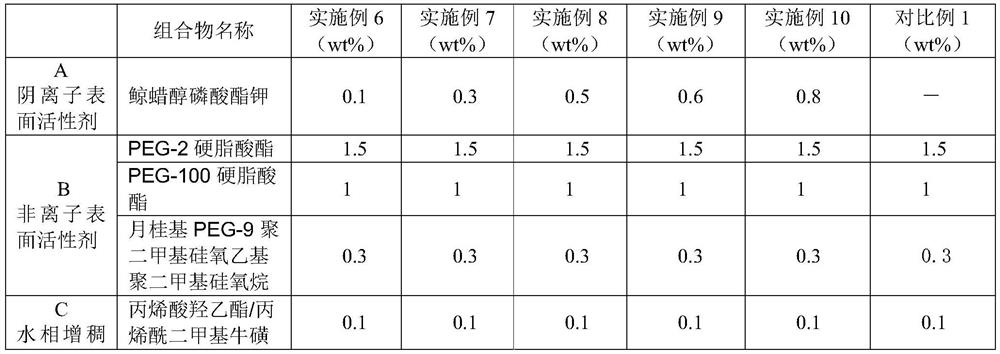

Examples

experiment example 1

[0056] Experimental example 1. Emulsion stability test:

[0057] To evaluate the stability of silicone oil-in-water emulsified cosmetics over time, each cosmetic product was placed in a transparent container and sealed with a cap, and then stored at 50°C for one month to observe any separation of the water and oil phases after storage . The shear viscosity of each cosmetic product was measured at 25°C using a rotational viscometer the day after formulation and after storage at 50°C for one month. From the second day after preparation to storage at 50°C for one month, the degree of oil-water phase separation and viscosity changes were observed and evaluated using four scales A to D. A: Consistent with the standard sample B: Slight changes, still applicable C: Moderate changes, unacceptable D: Significant changes, the results are listed in the tables in Table 1-4.

experiment example 2

[0058] Experimental example 2. Sensory evaluation:

[0059] In the single-use test on the skin conducted by the cosmetics evaluation expert group, the roughness, moisturizing feeling, moist feeling, thick feeling, and covering degree of the examples and comparative examples were evaluated, and the evaluation was scored (0-5 points) , the higher the score, the better the effect. The evaluation is carried out on the following scale: 1 point is very dissatisfied, 2 points are relatively dissatisfied, 3 points are average, 4 points are quite satisfactory, and 5 points are very satisfied. The results are listed in the tables in Table 1-4.

experiment example 3

[0060] Experimental example 3. Safety patch test:

[0061] Add 20 μL of the liquid to be tested dropwise to the spot tester, and the control hole is the blank control (pure water); stick the spot tester with the test substance on the flexion side of the forearm of the subject, and press lightly with the palm to make it evenly Stick it on the skin and last for 24 hours; observe the skin irritation and sensitization according to Table 5 after 30 minutes, 24 hours, and 48 hours after the spot tester is removed, and record the observation results.

[0062] table 5

[0063]

[0064] Experimental results: Human skin patch tests were carried out on Examples 3, 8, and 13. The results are shown in Table 6, and there were no adverse skin reactions among the 20 people.

[0065] Table 6

[0066]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com