Blue-light-proof and ultraviolet-proof polyester film as well as preparation method and application thereof

A polyester film and anti-ultraviolet technology, which is applied in applications, chemical instruments and methods, household appliances, etc., can solve the problems of large loss, serious secondary pollution, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

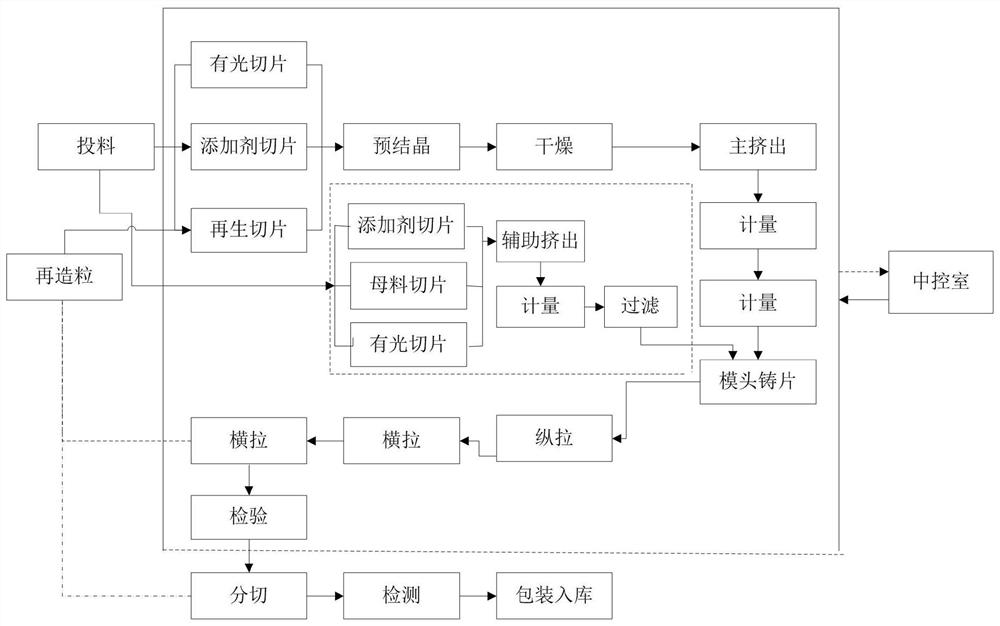

Method used

Image

Examples

Embodiment 1

[0046]An anti-blue light and anti-ultraviolet polyester film, comprising sequentially laminated layer A polyester film, layer B polyester film and layer C polyester film; layer A polyester film and layer C polyester film include the following raw materials in parts by weight : 30 parts of polyester chips, 70 parts of anti-blocking agent; wherein, the anti-blocking agent comprises the following raw materials in parts by weight: 99.72 parts of polyester, 2800 ppm of a mixture of silicon dioxide, kaolin, and barium sulfate in any proportion.

[0047] Layer B polyester film comprises the following raw materials in parts by weight: 65 parts of polyester chips, 12 parts of ultraviolet absorber, 15 parts of distyryl bisbenzoxazole, 8 parts of blue light absorber;

[0048] Wherein, the ultraviolet absorber includes the following raw materials in parts by weight: 90 parts of polyester, 2343 parts of BASF TINUVIN, 2343 parts of UVP-3273 parts and 15774 parts of BASF TINUVIN.

[0049] Th...

Embodiment 2

[0063] An anti-blue light and anti-ultraviolet polyester film, comprising sequentially laminated layer A polyester film, layer B polyester film and layer C polyester film; layer A polyester film and layer C polyester film include the following raw materials in parts by weight : 50 parts of polyester chips, 50 parts of anti-blocking agent; wherein, anti-blocking agent comprises the following raw materials in parts by weight: 99.68 parts of polyester, 3200 ppm of silicon dioxide, kaolin, and barium sulfate mixture in any proportion.

[0064] Layer B polyester film comprises the following raw materials in parts by weight: 72 parts of polyester chips, 10 parts of ultraviolet absorber, 10 parts of distyryl bisbenzoxazole, 8 parts of blue light absorber,

[0065] Wherein, the ultraviolet absorbent includes the following raw materials in parts by weight: 82 parts of polyester, 2346 parts of BASF TINUVIN, 2346 parts of UVP-3276 parts and 15776 parts of BASF TINUVIN.

[0066] The blue ...

Embodiment 3

[0080] An anti-blue light and anti-ultraviolet polyester film, comprising sequentially laminated layer A polyester film, layer B polyester film and layer C polyester film; layer A polyester film and layer C polyester film include the following raw materials in parts by weight 40 parts of polyester chips, 60 parts of anti-blocking agent; wherein, anti-blocking agent comprises the following raw materials in parts by weight: 99.70 parts of polyester, 3000 ppm of mixture of silicon dioxide, kaolin and barium sulfate in any proportion.

[0081] Layer B polyester film comprises the following raw materials in parts by weight: 80 parts of polyester chips, 7 parts of ultraviolet absorbers, 7 parts of distyryl bisbenzoxazoles, 6 parts of blue light absorbers,

[0082] Wherein, the ultraviolet absorber includes the following raw materials in parts by weight: polyester 85 parts, BASF TINUVIN 2346 parts, UVP-3275 parts and BASF TINUVIN 15774 parts.

[0083] The blue light absorbing agent i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| stretch ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com