Gap-adjustable exhaust block structure and die-casting die comprising same

A technology of die-casting molds and exhaust blocks, applied in the field of die-casting molds, can solve the problems of restricting the use of exhaust blocks with valves, low reliability of mechanical devices, and low matching accuracy, so as to increase the discharge/exhaust efficiency and improve compatibility. and reliability, the effect of ensuring safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

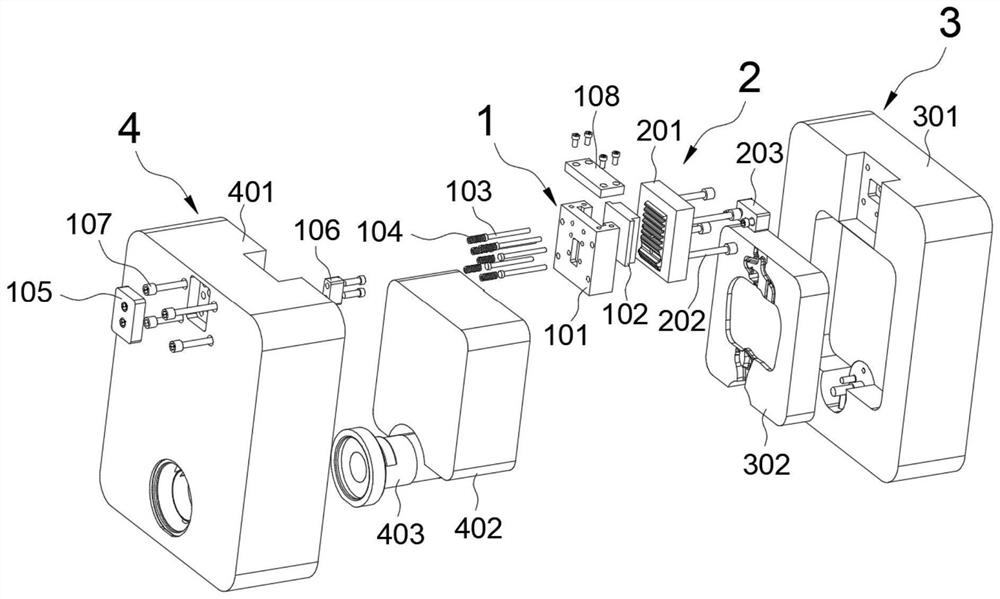

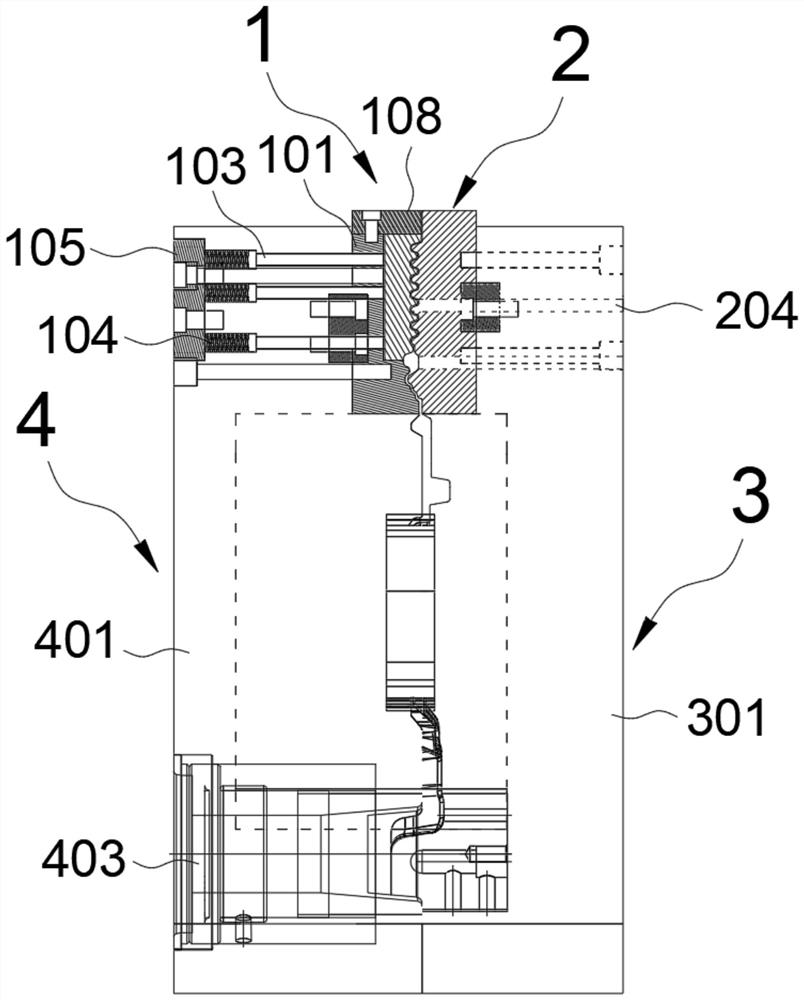

[0039] see figure 1 and figure 2 , the air-exhaust block structure with adjustable clearance in the preferred embodiment of the present invention includes a first air-exhaust block assembly 1 and a second air-exhaust block assembly 2, and the two air-exhaust block assemblies are respectively arranged on the movable die 3 and the fixed die 4 The corresponding matching of the two exhaust block assemblies can be completed after the movable mold 3 and the fixed mold 4 are matched and matched, and an exhaust gap is formed between the two.

[0040] Specifically, in the preferred embodiment, the first exhaust block assembly 1 is provided on the stationary mold 4 , and the second exhaust block assembly 2 is provided on the movable mold 3 . Wherein, the first exhaust block assembly 1 includes a first exhaust block 101, a movable exhaust block 102 and a pre-top elastic member, and the first exhaust block 101 is provided with a accommodating groove corresponding to the movable exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com