Special wrench assembly for porous flange plate and using method of special wrench assembly

A technology of wrenches and components, applied in the directions of wrenches, manufacturing tools, wrenches, etc., can solve the problems of limited number of nuts, unrealistic tightening, and uneven tightening of flange joints, and achieves low cost, simple structure, convenient The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

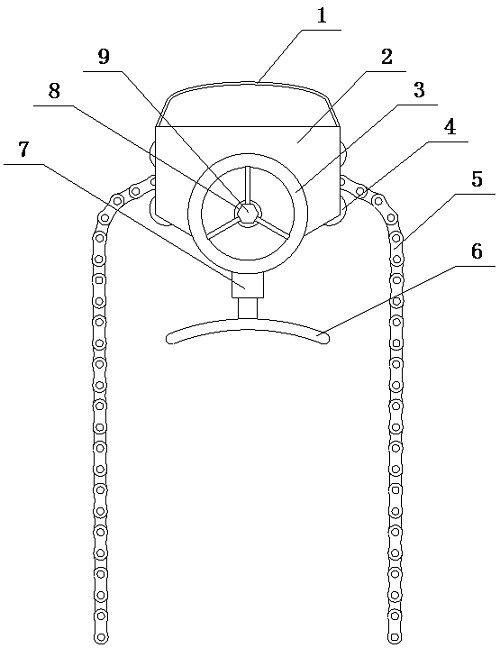

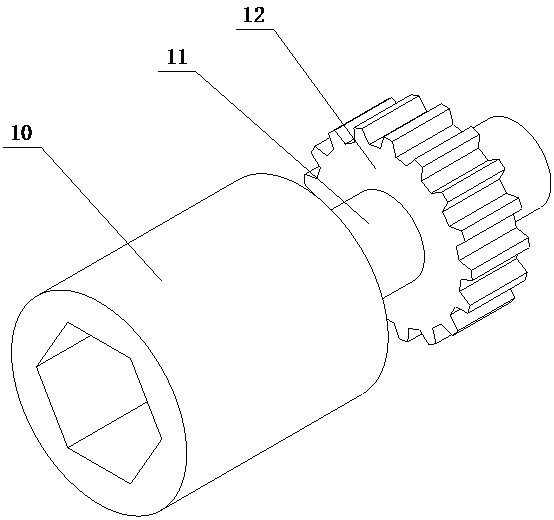

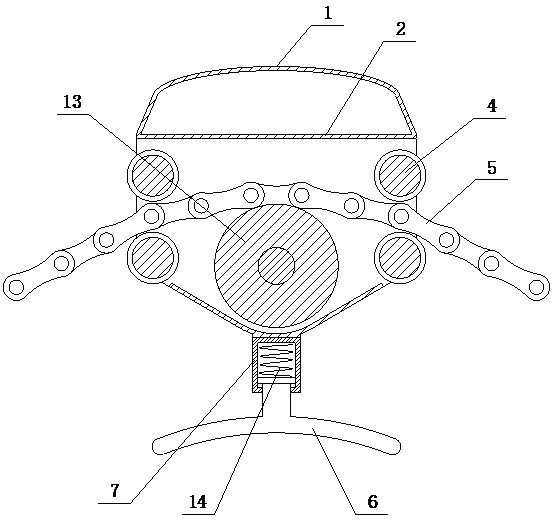

[0025] A special wrench assembly for a porous flange of the present invention is realized in this way, consisting of a handle (1), a main housing (2), a handle (3), a pulley (4), a chain (5), a support plate (6 ), telescopic cylinder (7), rotating shaft (8), hexagonal prism (9), nut sleeve (10), transmission shaft (11), transmission gear (12), drive gear (13) and spring (14), Two sets of pulleys (4) are placed inside the main housing (2), one set of pulleys (4) is composed of two pulleys (4), and the chain (5) is placed between the two pulleys (4) of the same set. The rotating shaft (8) is placed on the outer wall of the main housing (2), one end of the rotating shaft (8) is extended and placed inside the main housing (2), the driving gear (13) is placed on one end of the rotating shaft (8), and Located between the two sets of pulleys (4), the driving gear (13) and the chain (5) are meshed to form a transmission relationship. The hexagonal prism (9) is placed on the other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com