Precast pile lifting appliance

A technology of prefabricated piles and spreaders, applied in the direction of sheet pile walls, load hanging components, safety devices, etc., can solve problems such as safety hazards of high-altitude operations, and achieve the effect of reducing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is attached Figure 1-8 The application is described in further detail.

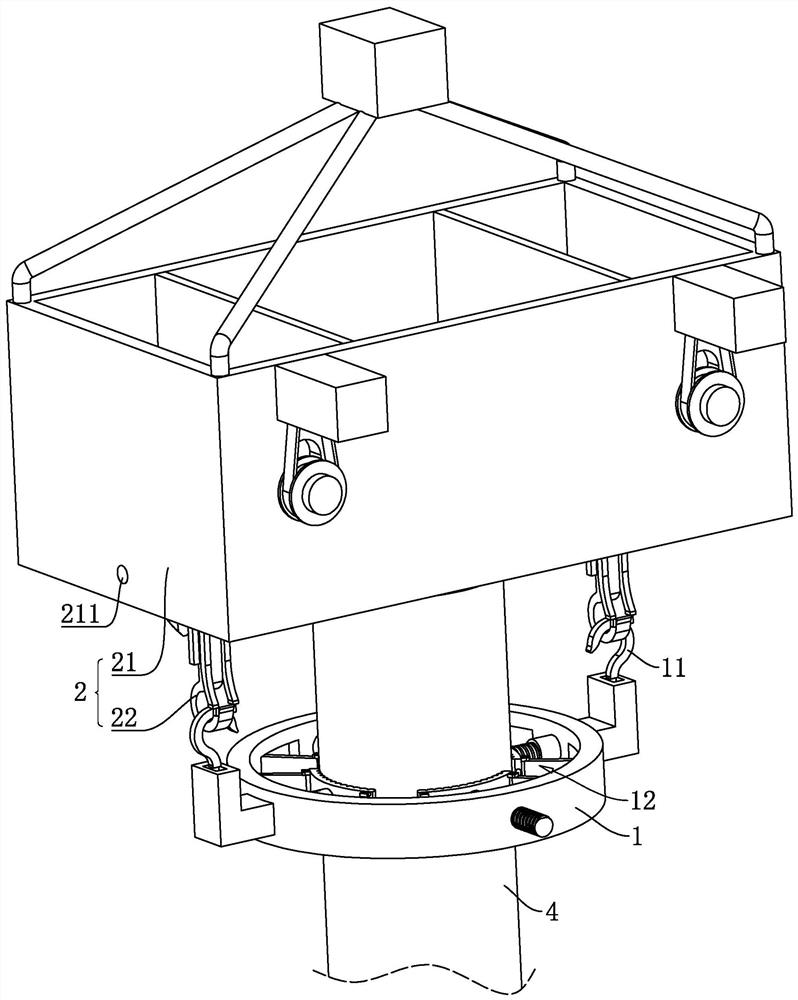

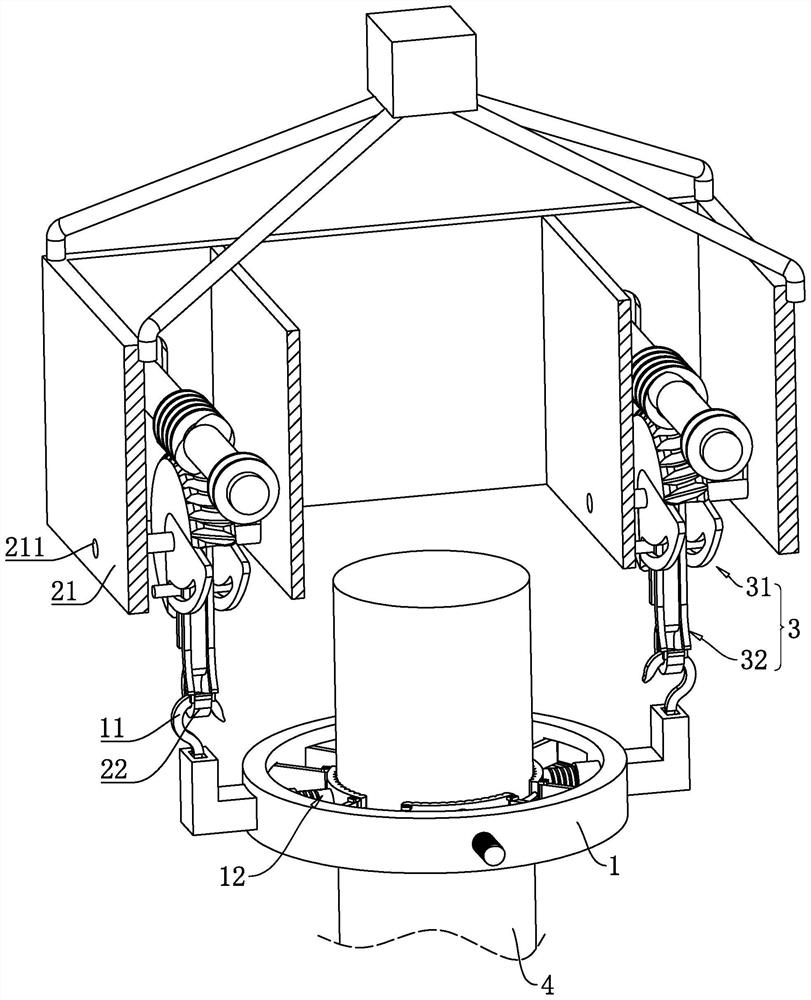

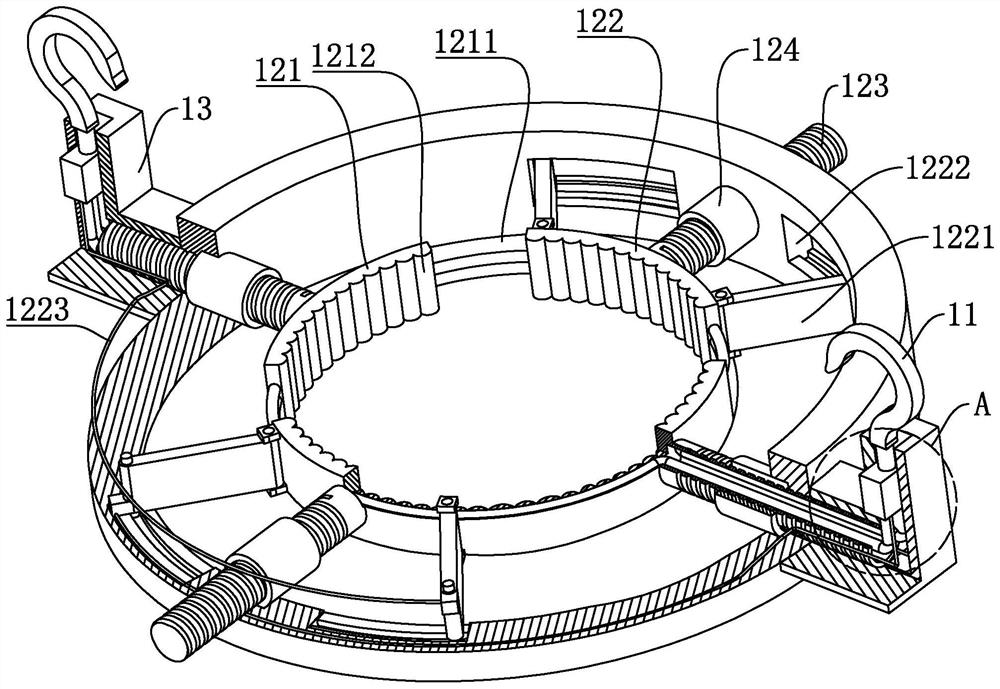

[0044] The embodiment of the application discloses a prefabricated pile spreader. refer to figure 1 and figure 2, a prefabricated pile spreader, including a fixed sleeve 1 sleeved on the precast pile 4, and a spreader body 2 connected with the fixed sleeve 1, the spreader body 2 is used to lift the precast pile 4. The circumferential direction of the fixed sleeve 1 is evenly provided with several hooks 11. In this embodiment, the number of hooks 11 is set to two, and the number of hooks 11 can also be three or four. Several hooks 11 are arranged along the circumference of the fixed sleeve 1. Arrange evenly. The inside of the fixing sleeve 1 is provided with a clamping mechanism 12 for locking the prefabricated pile 4 , so that the phenomenon of loosening between the fixing sleeve 1 and the prefabricated pile 4 is not easy to occur. The spreader body 2 includes a lifting box 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com