Multi-liquid composite micro-disturbance cement-soil mixing pile equipment

A cement-soil mixing pile and micro-disturbance technology, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, can solve the problems of spraying early strength liquid, damage, and large deformation, and achieve convenient installation, disassembly and maintenance, and fast setting time. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

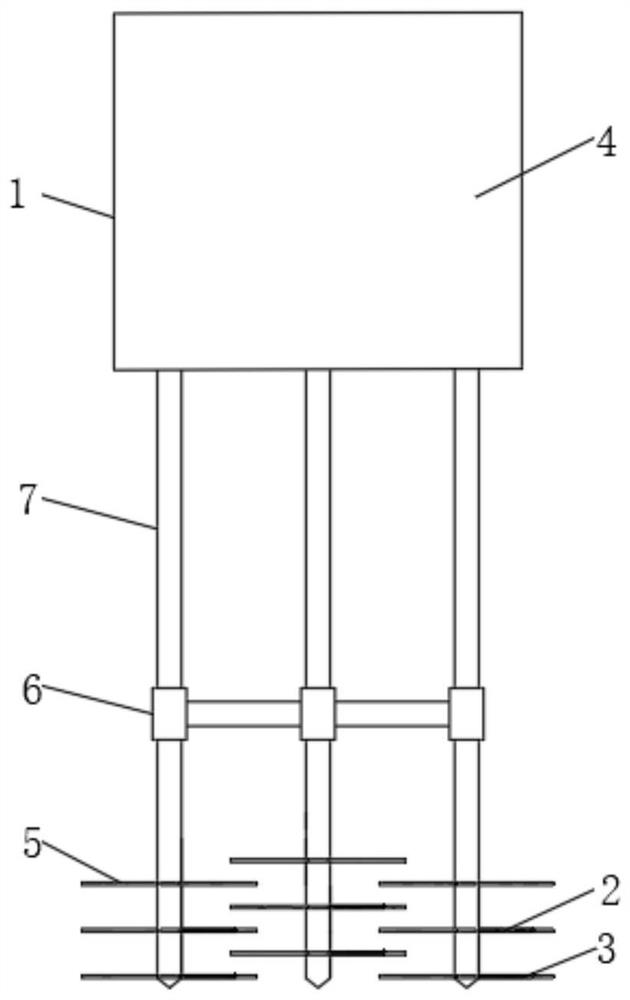

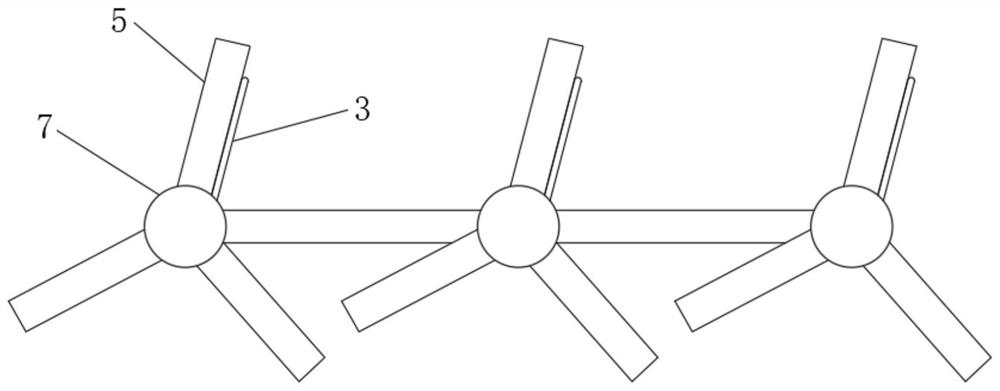

[0022] refer to Figure 1-2 , a multi-liquid composite micro-disturbance cement-soil mixing pile equipment, comprising a device body 1, the device body 1, the device body 1 includes a power head 4, a water glass nozzle 2, a multi-liquid gas nozzle 3, the The power head 4 is connected with a drive motor, the output end of the drive motor is connected with a drive rod 7, and the outside of the bottom of the drive rod 7 is connected with blades 5 equidistantly distributed, and the blade 5 at the bottom of the drive rod 7 is provided with three One side of the blade 5 of the second layer is equipped with a water glass nozzle 2, and one side of the blade 5 of the third layer is equipped with a multi-liquid gas nozzle 3, and the water glass nozzle 2 and the multi-liquid gas The bottoms of the nozzle pipes 3 are provided with nozzle holes distributed equidistantly, and the lower part of the drive rod 7 is fitted with a fixed frame 6;

[0023] More specifically, the top of the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com