Magnesium oxychloride cement-based double-liquid grouting material and preparation method thereof

A magnesium oxychloride cement and two-liquid grouting technology, which is applied in the field of construction engineering reinforcement, can solve problems such as poor construction performance, difficult setting time adjustment, etc., and achieves low requirements for production equipment and personnel, simple and easy preparation method, and low slurry good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of magnesium oxychloride cement-based two-liquid grouting material of the present invention comprises the steps:

[0039] The first step is to weigh the corresponding raw materials according to the weight parts of A powder and B powder, and mix them evenly to prepare A powder and B powder respectively;

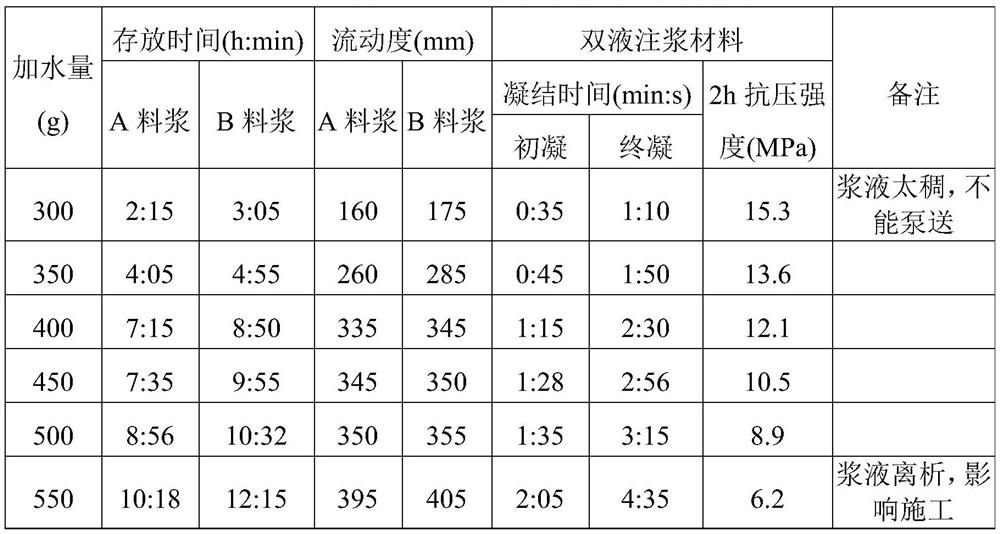

[0040] In the second step, the A powder component and water are mixed uniformly according to the weight ratio of A powder: water = 100: (35-50) to prepare A slurry; the B powder component and water are mixed according to the B powder : water=100: (35~50) weight ratio mixes evenly, makes B slurry;

[0041] In the third step, the A slurry and the B slurry are uniformly mixed in the same volume to obtain the magnesium oxychloride cement-based two-component grouting material.

Embodiment 1

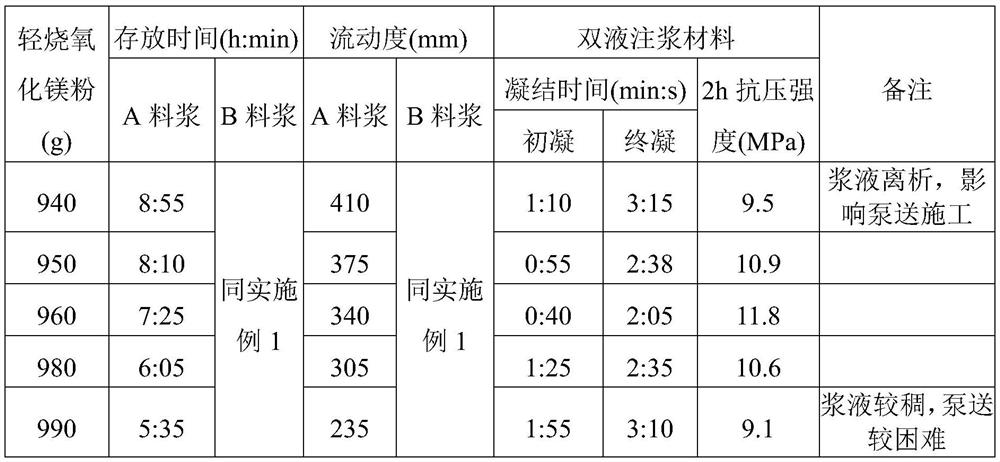

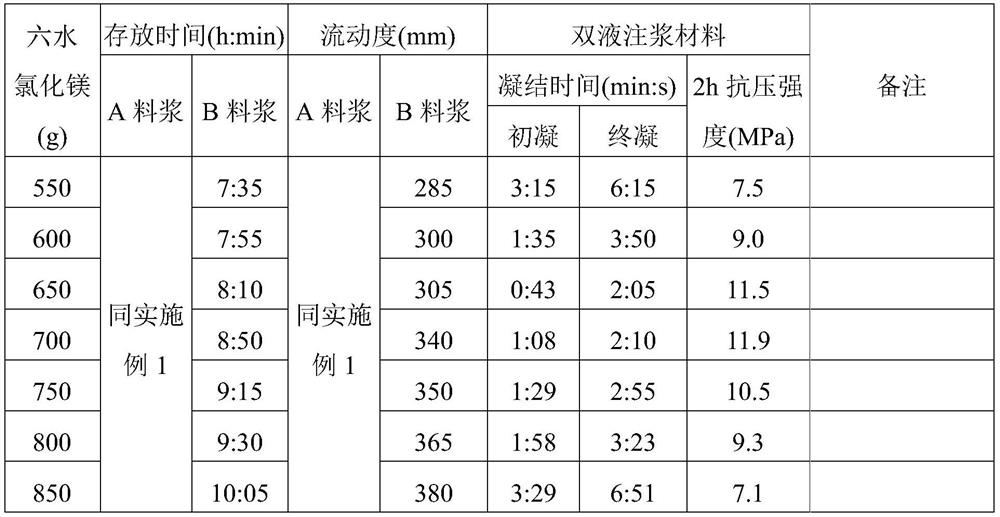

[0043]The magnesium oxychloride cement-based double-liquid grouting material of this embodiment is formed by mixing A slurry and B slurry at a volume ratio of 1:1, wherein: A slurry consists of 970g lightly burned magnesium oxide powder and 20g water reducer , 10g hydroxypropyl methylcellulose and 380g water are mixed, B slurry is composed of 660g magnesium chloride hexahydrate, 150g potassium dihydrogen phosphate, 150g sodium dihydrogen phosphate, 30g water reducer, 10g hydroxypropyl methylcellulose Mix with 380g of water.

[0044] The preparation method of the magnesium oxychloride cement-based two-liquid grouting material of the present embodiment may further comprise the steps:

[0045] Step 1: Take light-burned magnesia, water reducer, and hydroxypropyl methylcellulose according to the above weight, and mix them uniformly to obtain A powder;

[0046] Step 2, take magnesium chloride hexahydrate, potassium dihydrogen phosphate, sodium dihydrogen phosphate, water reducer, h...

Embodiment 2

[0053] The magnesium oxychloride cement-based double-liquid grouting material of this embodiment is formed by mixing A slurry and B slurry in a volume ratio of 1:1, wherein: A slurry consists of 980g lightly burned magnesia powder and 15g water reducer , 5g hydroxypropyl methylcellulose and 450g water are mixed, B slurry is composed of 700g magnesium chloride hexahydrate, 150g potassium dihydrogen phosphate, 120g sodium dihydrogen phosphate, 20g water reducer, 10g hydroxypropyl methylcellulose Mix with 450g of water.

[0054] The preparation method of the magnesium oxychloride cement-based two-liquid grouting material of the present embodiment may further comprise the steps:

[0055] Step 1: Take light-burned magnesia, water reducer, and hydroxypropyl methylcellulose according to the above weight, and mix them uniformly to obtain A powder;

[0056] Step 2, take magnesium chloride hexahydrate, potassium dihydrogen phosphate, sodium dihydrogen phosphate, water reducer, hydroxyp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com