Formaldehyde-free multi-layer solid wood composite floor and production process thereof

A technology of solid wood composite floor and production process, which is applied to insulation layers, floors, heating appliances for treatment, etc. Heat compress effect, easy to use, reduce the effect of allergens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

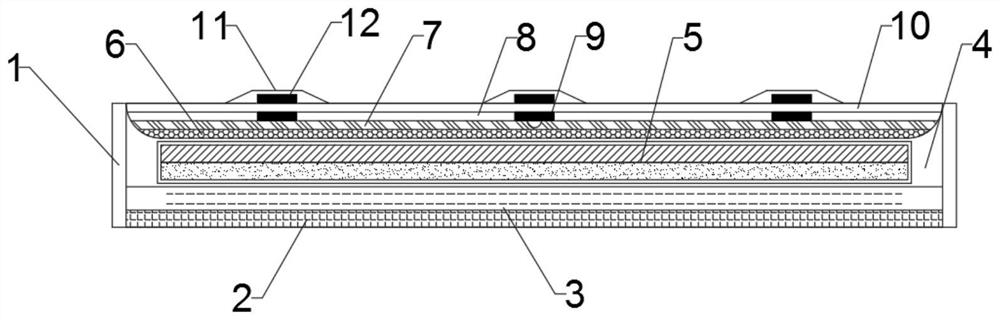

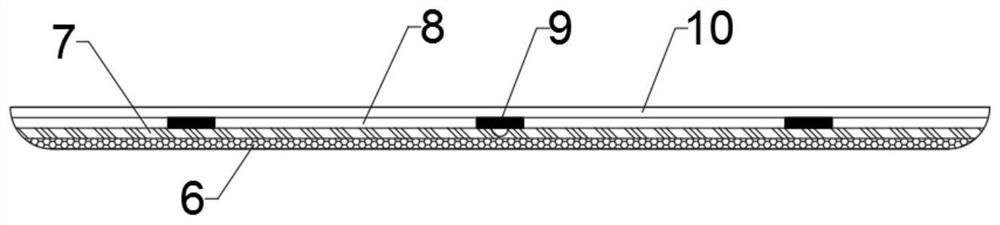

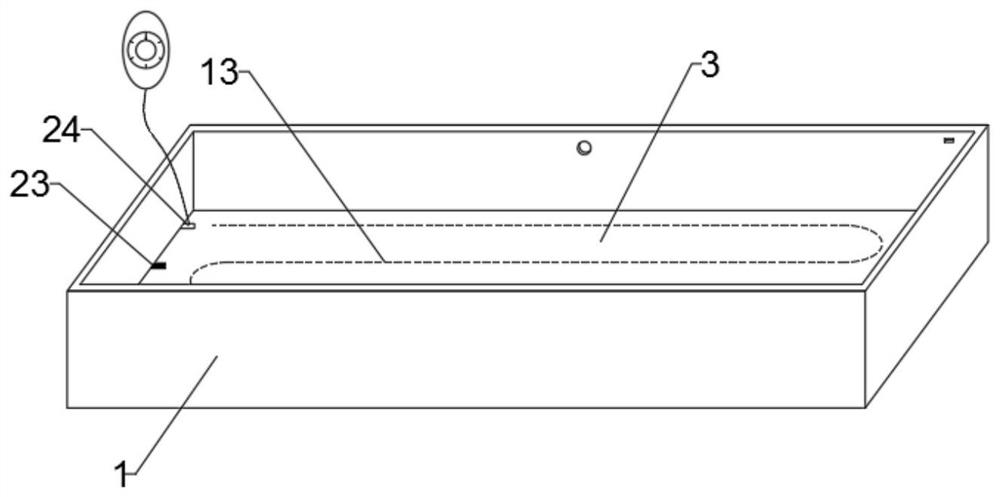

[0029] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0030] Such as Figure 1-Figure 7 As shown, the formaldehyde-free multi-layer solid wood composite floor provided by this embodiment includes a frame body 1 and a fixed group and a mobile group installed inside the frame body 1 sequentially from bottom to top. The heating layer 3 on the top of the layer 2, the inside of the heating layer 3 is laid with a heating wire 13, the medicinal material layer 4 is arranged between the fixed group and the moving group, the inner part of the medicinal material layer 4 is provided with a temperature sensor 23, and one side of the temperature sensor 23 is provided with There is a signal transmitter 24, and the inside of the medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com