A method and device for ultra-low temperature spinning forming of aluminum alloy curved busbar components

A technology of spinning forming and curved bus bar, which is applied in the direction of forming tools, metal processing, metal processing equipment, etc., can solve the problems of rapid and efficient production of large aluminum alloy curved bus bar components, component size constraints, and long processing cycles. Achieve the effect of weakening PLC effect, improving strength and plasticity, and increasing work hardening rate

Active Publication Date: 2022-06-03

CENT SOUTH UNIV

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the need for deep drawing and preforming before spinning, the size of the component is restricted by the size of the press table and the tonnage

At the same time, annealing treatment is required between different passes of spinning forming, and the assembly workpiece needs to be transferred multiple times, the process is complex and the processing cycle is long

It is difficult to realize the rapid and efficient production and manufacture of large aluminum alloy curved busbar components, and for aluminum alloys with high alloying degree and poor plasticity, the problem of cracking during forming cannot be solved only by trajectory planning and adjustment of machine tool processing parameters.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

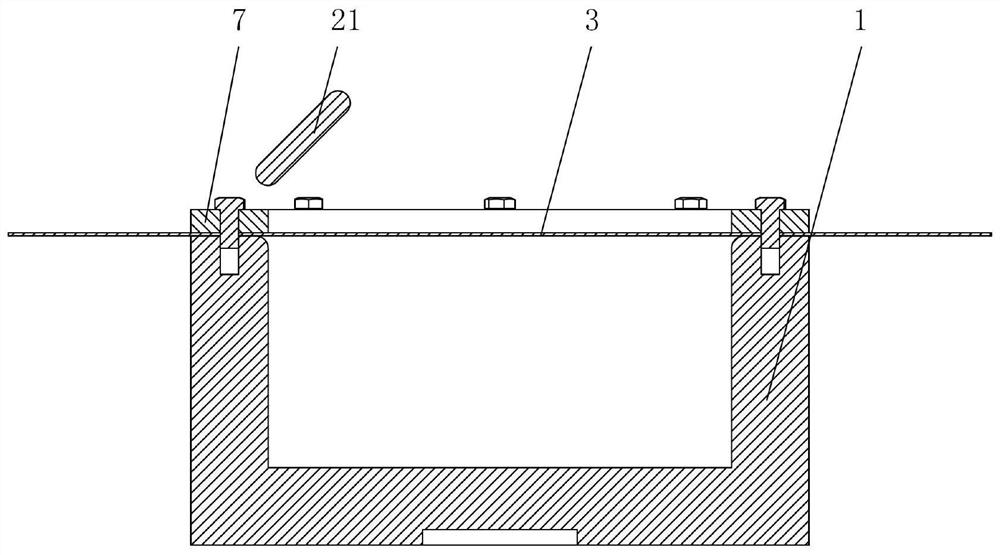

[0044] S4: forming is completed: the forming is completed, and the forming workpiece is taken out.

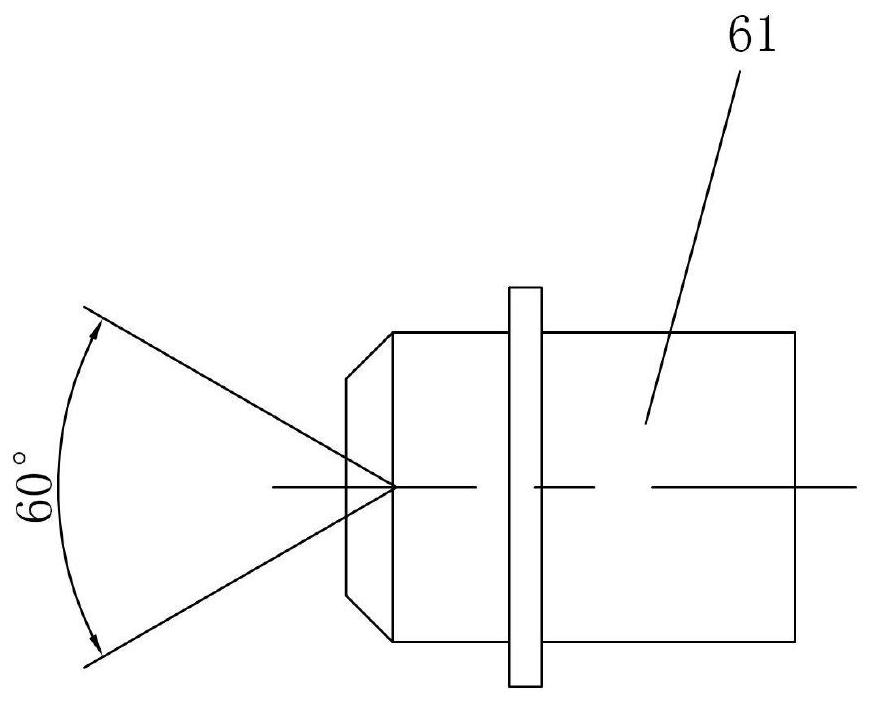

[0048] In this embodiment, the fillet radius of the cutter wheel 21 is 6mm to 8mm, and in this embodiment, it is set to 8mm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Login to View More

Abstract

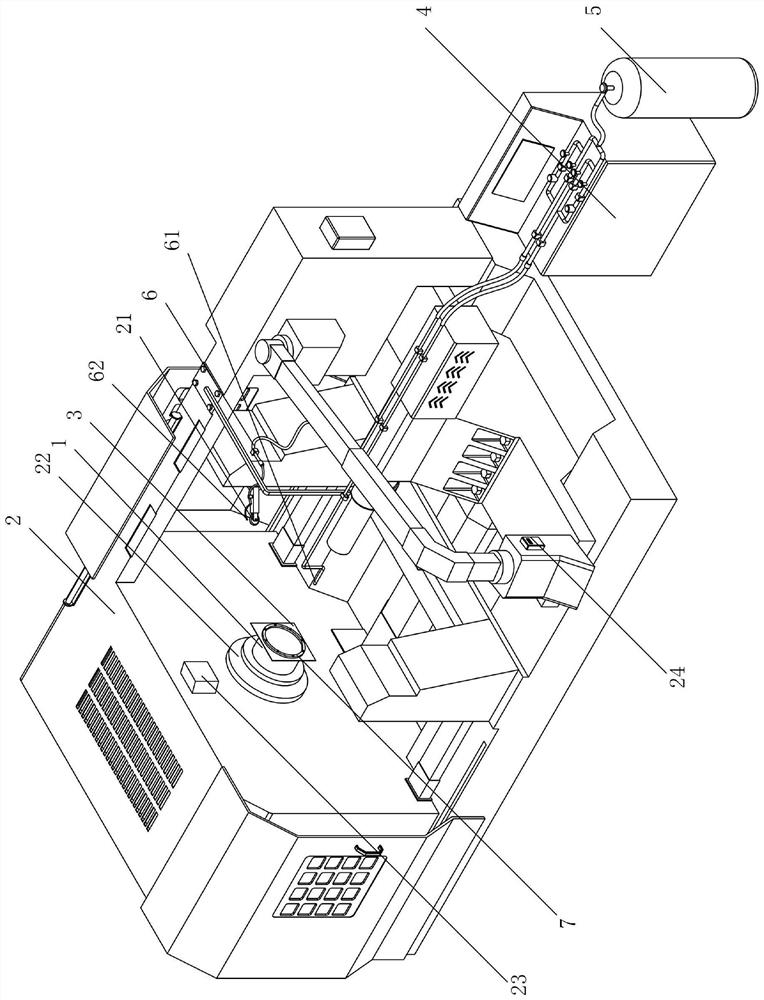

The invention discloses an ultra-low temperature spinning forming method and device for an aluminum alloy curved busbar component. The forming method sequentially performs forming steps such as die clamping, blank precooling, and spinning processing, so as to realize spinning forming of the blank under ultra-low temperature conditions Processing, and there is always a clear gap between the blank and the die during the processing process, which prevents the local performance weakening, cracking and stress concentration of the workpiece under the ultra-low temperature environment, and greatly improves the yield and processing quality. The forming method of the present invention has the advantages of convenient implementation, high forming efficiency, good product integrity and good quality performance; the device used to realize the ultra-low temperature spinning forming method of the aluminum alloy curved busbar component also has the above advantages.

Description

A kind of ultra-low temperature spinning forming method and device for aluminum alloy curved generatrix member technical field The present invention relates to sheet metal forming technical field, relate in particular to a kind of ultra-low temperature spinning forming of aluminum alloy curved generatrix member method and apparatus. Background technique Along with the continuous improvement of scientific and technological strength, my country's aerospace technology and strength are developing rapidly, and the launch vehicle is growing rapidly. Type, integration, lightweight development. The bottom of the rocket fuel tank is a typical representative of an aluminum alloy curved busbar component. The ambient temperature is low, the load is large and the working environment is extremely complex. Because of its high diameter-to-thickness ratio, large curvature, and deep depth It is extremely difficult to realize the overall forming. At present, the bottom forming proces...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B21D22/16B21D37/16B21D37/18B21C51/00

CPCB21D22/16B21D37/16B21D37/18B21C51/00Y02P10/25

Inventor 易幼平黄始全张劲黄珂

Owner CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com