Mechanical arm decentralized optimal fault-tolerant control method considering actuator faults

A fault-tolerant control and actuator technology, used in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as damage, exceeding the maximum output limit of the actuator, and huge fluctuations in the output of the actuator, achieving rapid judgment, providing stability and reliability. Accuracy, the effect of reducing output consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be described in further detail below in conjunction with the accompanying drawings.

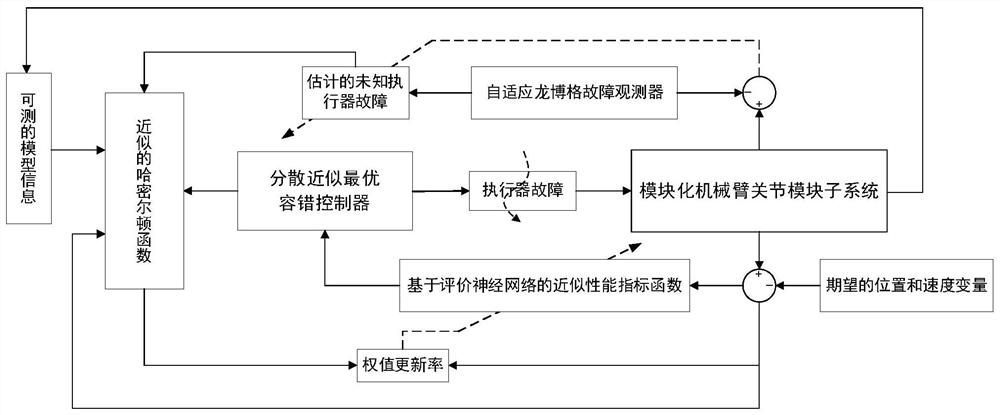

[0073] Such as figure 1 As shown, the present invention relates to a decentralized optimal fault-tolerant control method of a manipulator considering actuator faults. The specific implementation method and process are as follows:

[0074] 1. Establishment of dynamic model of joint module subsystem based on joint torque sensor

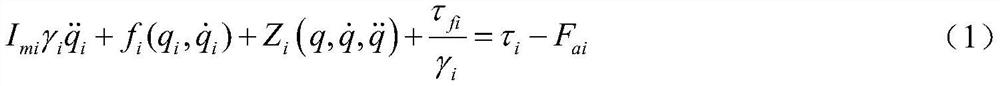

[0075] Considering the unknown actuator fault, the dynamic model of the n-degree-of-freedom modular manipulator system based on joint torque feedback technology is expressed as:

[0076]

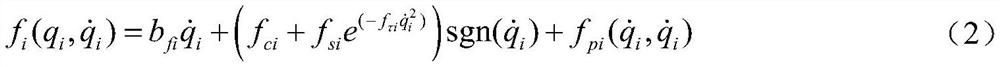

[0077] Among them, q i is the i-th joint position; is the joint angular velocity; is the joint angular acceleration; I mi is the moment of inertia of the motor; γ i is the reduction ratio of the reducer; Dynamically coupled cross-link terms between joints, is the information including the position, velocity and acceleration of all join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com