A semiconductor graphene nanoribbon and its preparation method and application

A graphene nanobelt and semiconductor technology, applied in graphene, semiconductor devices, nano-carbon, etc., can solve the problems of opening and inability to apply semiconductor devices, etc., and achieve the effect of simple production process route, good uniformity and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

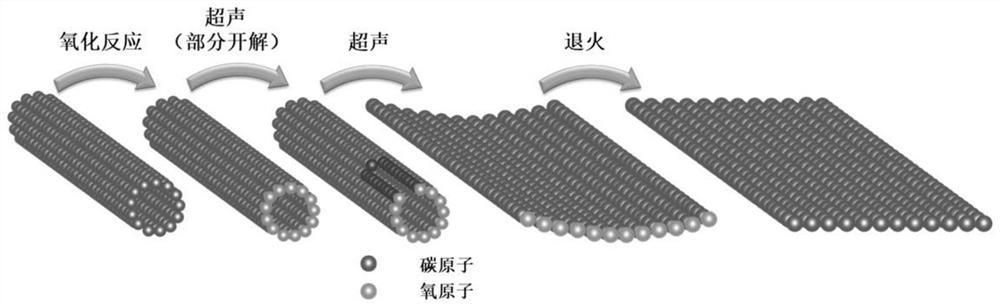

Method used

Image

Examples

Embodiment 1

[0052] A preparation method of semiconductor graphene nanoribbon, comprising steps as follows:

[0053] (1) Preparation of single-walled carbon nanotube suspension:

[0054] 50 mg of single-walled carbon nanotubes with a diameter of 1.3 nm were annealed in air at 300 ° C for 30 minutes to effectively remove the amorphous carbon mixed therein; then the annealed single-walled carbon nanotubes were added to 50 mL concentrated sulfuric acid with a mass fraction of 98 wt%, and stirred for 2 hours to obtain a suspension of single-walled carbon nanotubes.

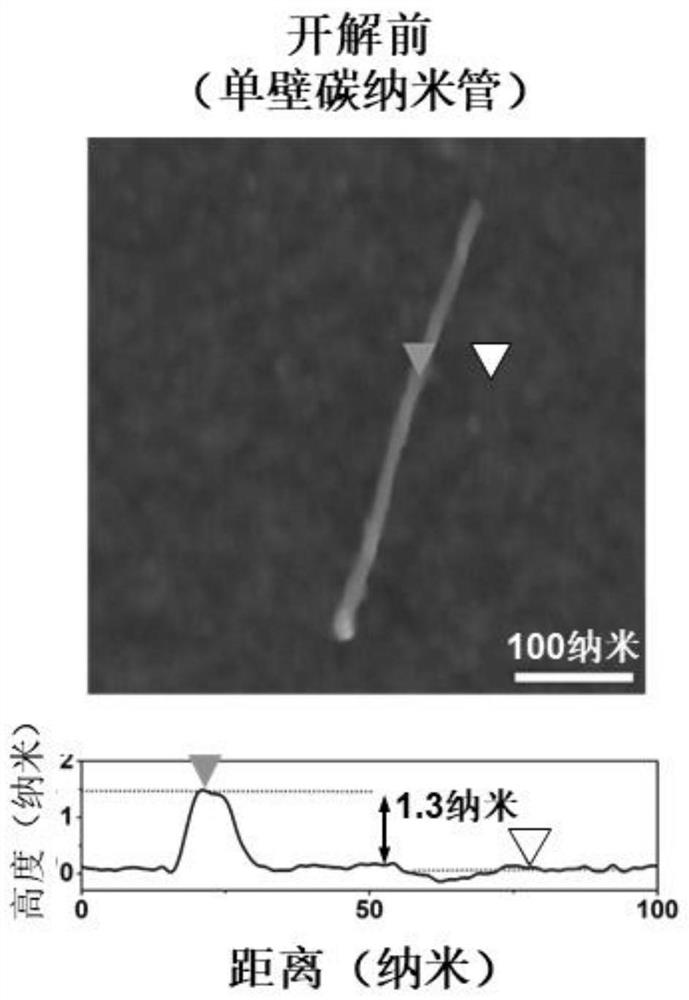

[0055] The atomic force microscope photo of the single-walled carbon nanotubes used in this step is as follows: figure 2 shown, from figure 2 As can be seen in , the single-walled carbon nanotubes used have a diameter of 1.3 nm.

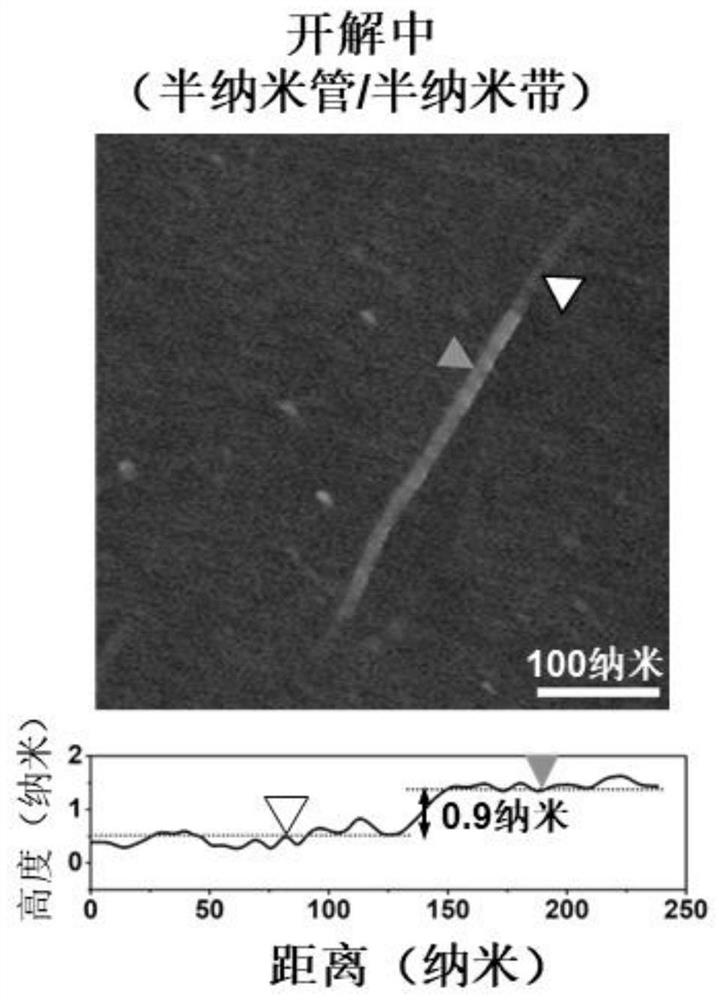

[0056] (2) Preparation of single-walled carbon nanotubes with defects:

[0057] 25 mg of potassium permanganate was gradually added to the single-walled carbon nanotube suspension obtained in step ...

Embodiment 2

[0068] A preparation method of semiconductor graphene nanoribbon, comprising steps as follows:

[0069] (1) Preparation of single-walled carbon nanotube suspension:

[0070] 50 mg of single-walled carbon nanotubes with a diameter of 1.3 nm were annealed in air at 300 ° C for 60 minutes to effectively remove the amorphous carbon mixed therein; then the annealed single-walled carbon nanotubes were added to 100 mL concentrated sulfuric acid with a mass fraction of 98 wt%, and stirred for 2 hours to obtain a suspension of single-walled carbon nanotubes.

[0071] (2) Preparation of single-walled carbon nanotubes with defects:

[0072] Gradually add 25 mg of potassium permanganate to the single-walled carbon nanotube suspension obtained in step (1), and react at 45° C. for 60 minutes; after the reaction is completed, pour the resulting reaction solution into 400 mL of ice water, and then The single-walled carbon nanotubes with defects were obtained by filtering with an ethylene fi...

Embodiment 3

[0078] A preparation method of semiconductor graphene nanoribbon, comprising steps as follows:

[0079] (1) Preparation of single-walled carbon nanotube suspension:

[0080] 50 mg of single-walled carbon nanotubes with a diameter of 1.3 nm were annealed in air at 350 ° C for 60 minutes to effectively remove the amorphous carbon mixed therein; then the annealed single-walled carbon nanotubes were added to 100 mL concentrated sulfuric acid with a mass fraction of 98 wt%, and stirred for 2 hours to obtain a suspension of single-walled carbon nanotubes.

[0081] (2) Preparation of single-walled carbon nanotubes with defects:

[0082] Gradually add 25 mg of potassium permanganate to the single-walled carbon nanotube suspension obtained in step (1), and react at 60° C. for 30 minutes; after the reaction is completed, pour the resulting reaction solution into 800 mL of ice water, and then The single-walled carbon nanotubes with defects were obtained by filtering with an ethylene fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com