Temperature-resistant and salt-resistant water-based drilling fluid filtrate reducer and preparation method thereof

A technology of fluid loss reducer and drilling fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high cost, poor temperature and salt resistance, etc., and achieve enhanced salt resistance and improved temperature resistance Ability, the effect of improving the ability of temperature resistance and salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

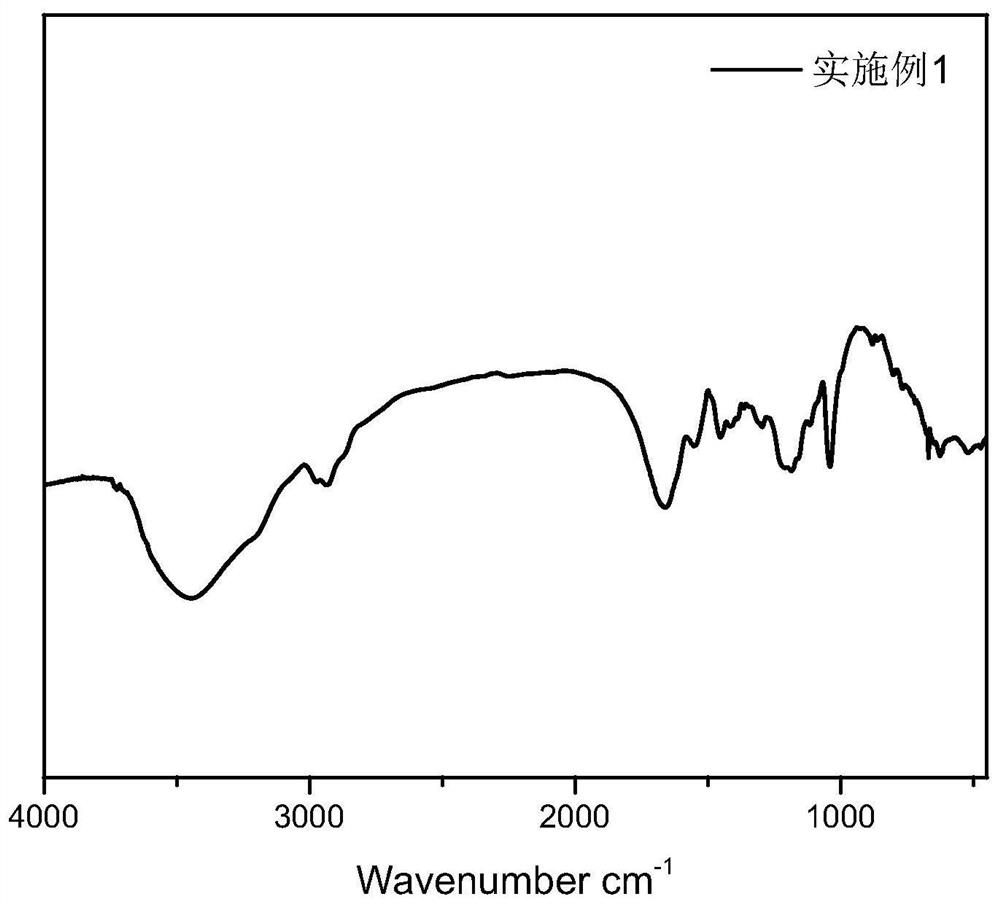

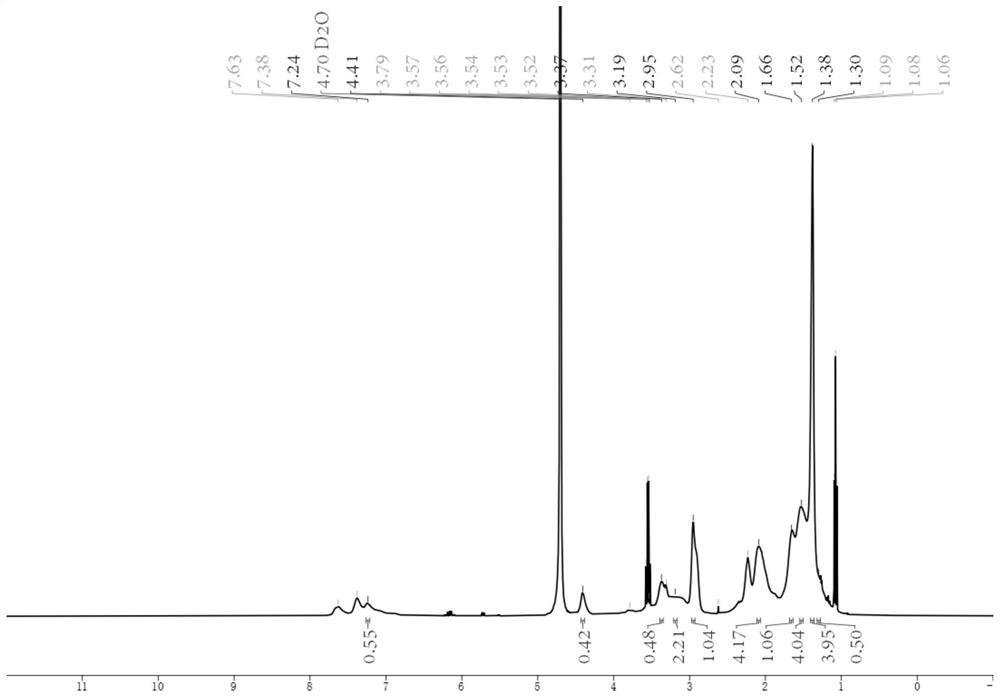

Embodiment 1

[0031] Add 520g of water, 60g of acrylamide, 43.6g of 2-acrylamido-2 methylpropanesulfonic acid, 11.7g of N-vinylpyrrolidone to a four-necked flask equipped with a stirrer, reflux condenser, thermometer and heating device 1. No. 15g zwitterionic monomer (1), start the stirrer until all the monomers are dissolved. Then add NaOH to adjust the pH to 6.0, then pass nitrogen to drive oxygen, and heat after passing nitrogen. When the temperature rises to 45°C, add 0.26g ammonium persulfate, add 0.095g sodium bisulfite, and continue to pass nitrogen for half an hour. Then stop feeding nitrogen.

[0032] The reaction lasted for 4 hours, and the stirring speed was fixed at 300 rpm. After 4 hours, the semi-solid polymer was poured into an ethanol solution for purification, cut into pieces and granulated, and then dried in an oven at 50°C.

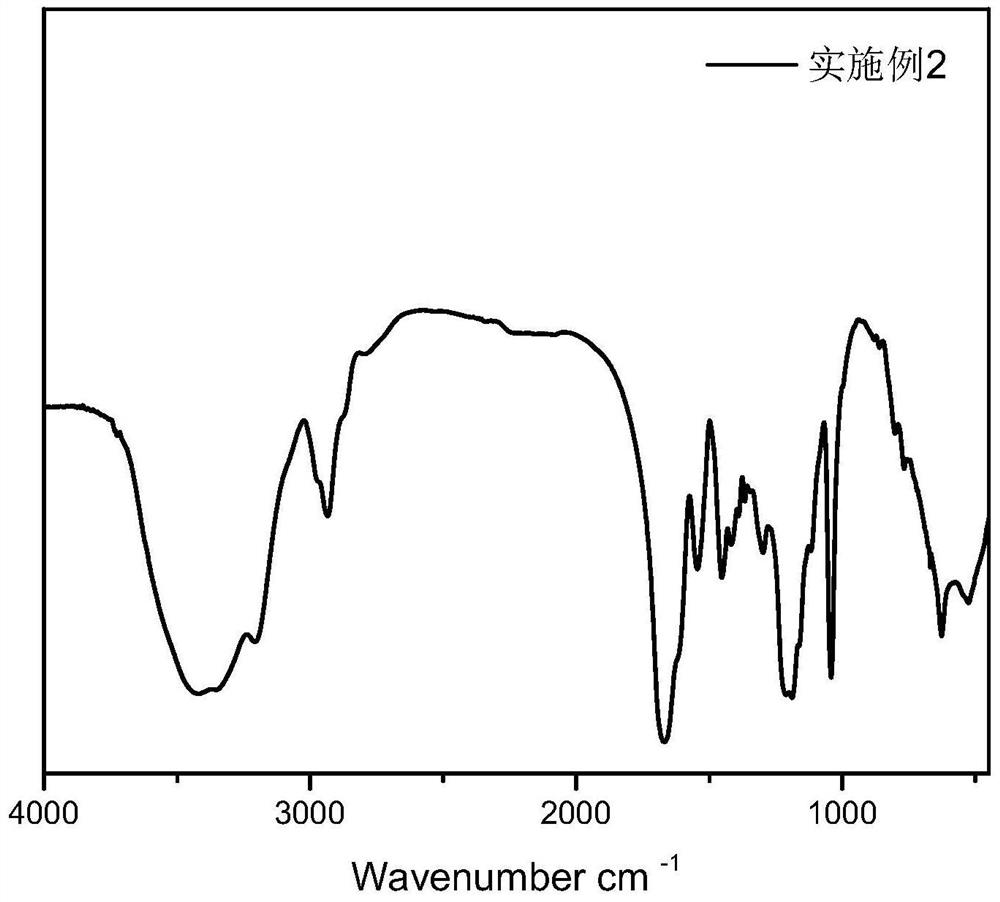

Embodiment 2

[0034] In this example, to a four-necked flask equipped with a stirrer, a reflux condenser thermometer and a heating device, 489g of water, 60g of acrylamide, 58g of 2-acrylamido-2 methylpropanesulfonic acid, 15g of N-ethylene Base pyrrolidone, No. 30g zwitterionic monomer (2), start the stirrer, until all monomers are dissolved. Then add NaOH to adjust the pH to 7.0, then pass nitrogen to drive oxygen, and heat after passing nitrogen. When the temperature rises to 50°C, add 0.815g ammonium persulfate, add 0.340g sodium bisulfite, and continue to pass nitrogen for half an hour. stop after.

[0035] The reaction lasted for 8 hours, and the stirring speed was fixed at 400rpm. After 8 hours, the semi-solid polymer was poured into the ethanol solution for purification, cut into pieces and granulated, and then dried in an oven at 65°C. After drying, the white particles were obtained. Filtrate reducer.

Embodiment 3

[0037] In this example, 306g of water, 40g of acrylamide, 58.3g of 2-acrylamido-2 methylpropanesulfonic acid, 15.6g of N - Vinylpyrrolidone, No. 37.47g zwitterionic monomer (3), start the stirrer until all the monomers are dissolved. Then add NaOH to adjust the pH to 11, then pass nitrogen to drive oxygen, heat after passing nitrogen, wait for the temperature to rise to 65°C, add 1.36g ammonium persulfate, add 0.663g sodium bisulfite, continue to pass nitrogen, half an hour stop after.

[0038] The reaction lasted for 10 hours, and the stirring speed was fixed at 600rpm. After 10 hours, the semi-solid polymer was poured into the ethanol solution for purification, cut into pieces and granulated, and then dried in an oven at 80°C. After drying, the white particles were obtained. Filtrate reducer.

[0039] (2) Performance test experiment

[0040] In this example, the fluid loss control agents prepared in Examples 1-3 were used for experiments.

[0041] Configuration of fresh ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap