Anti-punching steel truss

A punching-resistance, steel truss technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of inability to improve the seismic performance of the structure, and the force of the punching-resistant key cannot be fully exerted, so as to improve the impact of punching. Performance and elastic-plastic deformation ability, improved safety and shock resistance, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

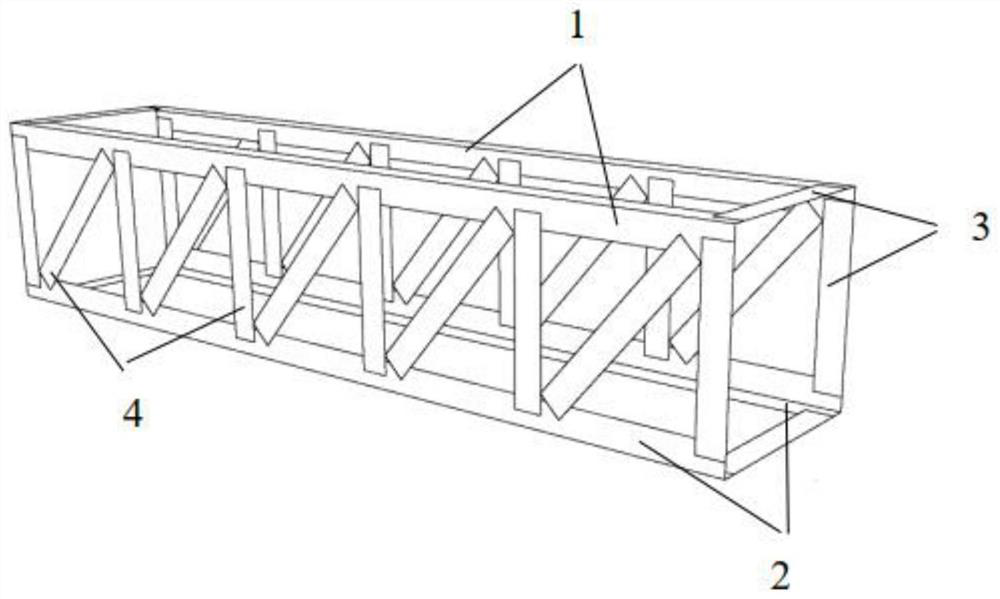

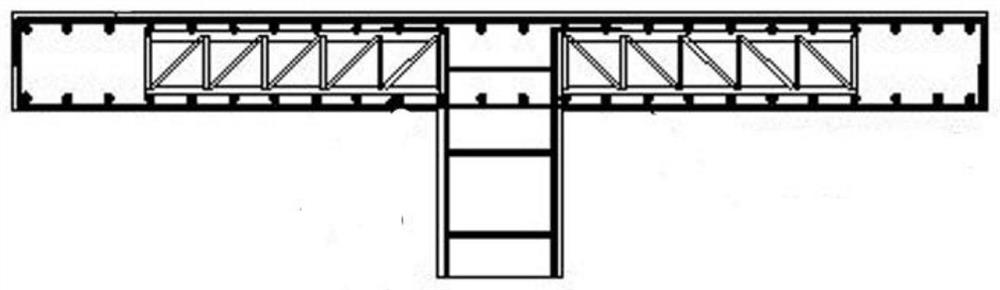

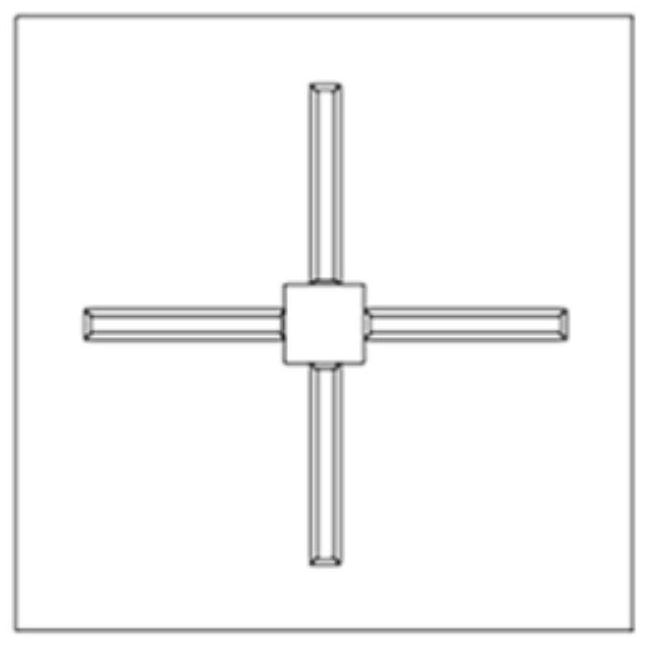

[0024] Such as figure 1 As shown, the punching shear resistant steel truss is welded by the upper longitudinal chord 1, the lower longitudinal chord 2, the connecting web 3 and the punching resisting web 4, among which the punching resisting web There are two types: vertical and oblique. The upper longitudinal chord 1 and the lower longitudinal chord 2 are used to form a spatial structure system by using the connecting web 3, and a plurality of punching-resistant webs 4 are respectively placed on both sides of the vertical direction to the plate plane, wherein The oblique web and the lower longitudinal chord 2 form an angle of 45°.

[0025] The anti-punching steel truss of the present invention is designed as an integrated structure, that is, the upper longitudinal chord 1, the lower longitudinal chord 2, the connecting web 3 and the punching-resistant web ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com