Sealing structure for soluble bridge plug

A sealing structure and soluble technology, used in sealing/isolation, wellbore/well components, earth-moving drilling, etc. Meet the requirements of on-site use and improve the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

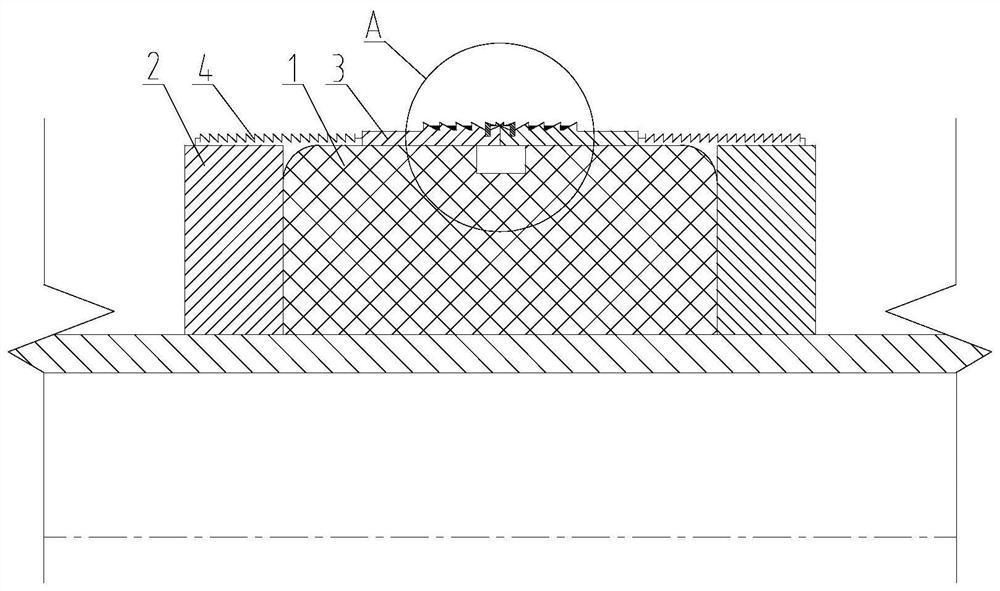

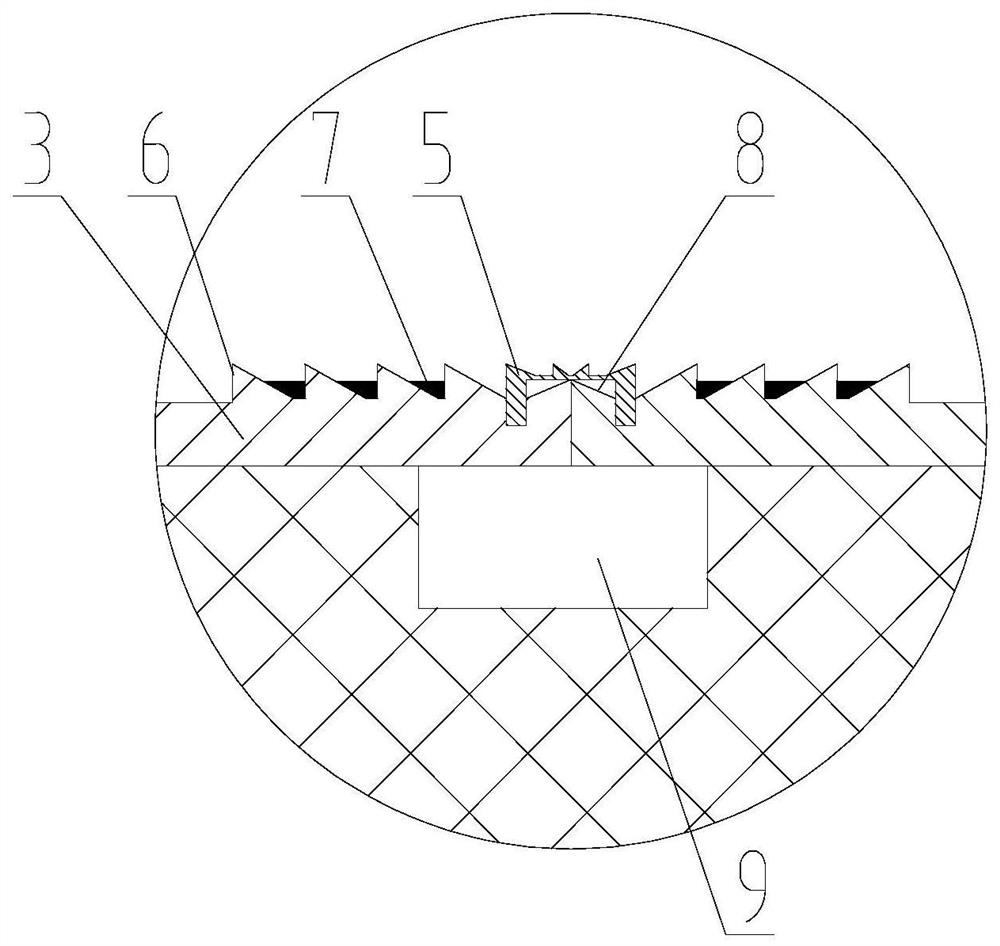

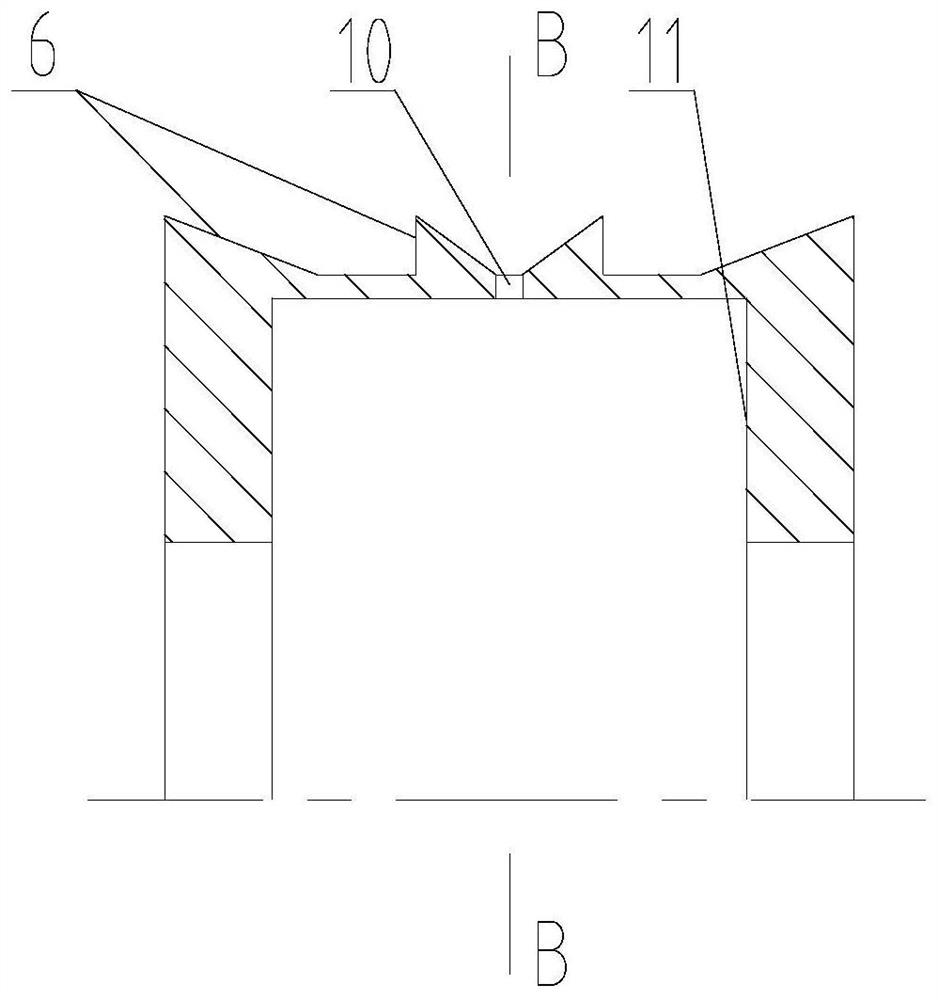

[0021] Depend on figure 1 combine Figure 2-5 As shown, a sealing structure for dissolvable bridge plugs includes a rubber barrel 1 and retaining rings 2 on both sides of the rubber barrel 1. The rubber barrel 1 and retaining rings 2 on both sides are sleeved on the central tube of the bridge plug. There are two symmetrically installed push rings 3 on the outer sleeve of the barrel 1. The docking position of the two push rings 3 is in the middle of the rubber barrel 1. The two push rings 3 are connected through the connecting buckle 5. Each push ring 3 and the retaining ring 2 There is a tension spring 4 connection between them, the cross-section of the connecting buckle 5 is U-shaped, and the facade ring plates 11 on both sides of the U-shaped connecting buckle 5 are stuck in the ring groove of the push ring 3;

[0022] On the inner side of the two facade ring plates 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com