A Fast and Accurate Method for Detecting Coal-rock Boundary

A coal-rock boundary and coal-rock layer technology is applied in the field of rapid and accurate detection of coal-rock layer boundaries, which can solve the problems of high labor and material cost, long time required for drilling detection, inaccurate detection, etc., and achieves continuous testing, testing workload and The effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

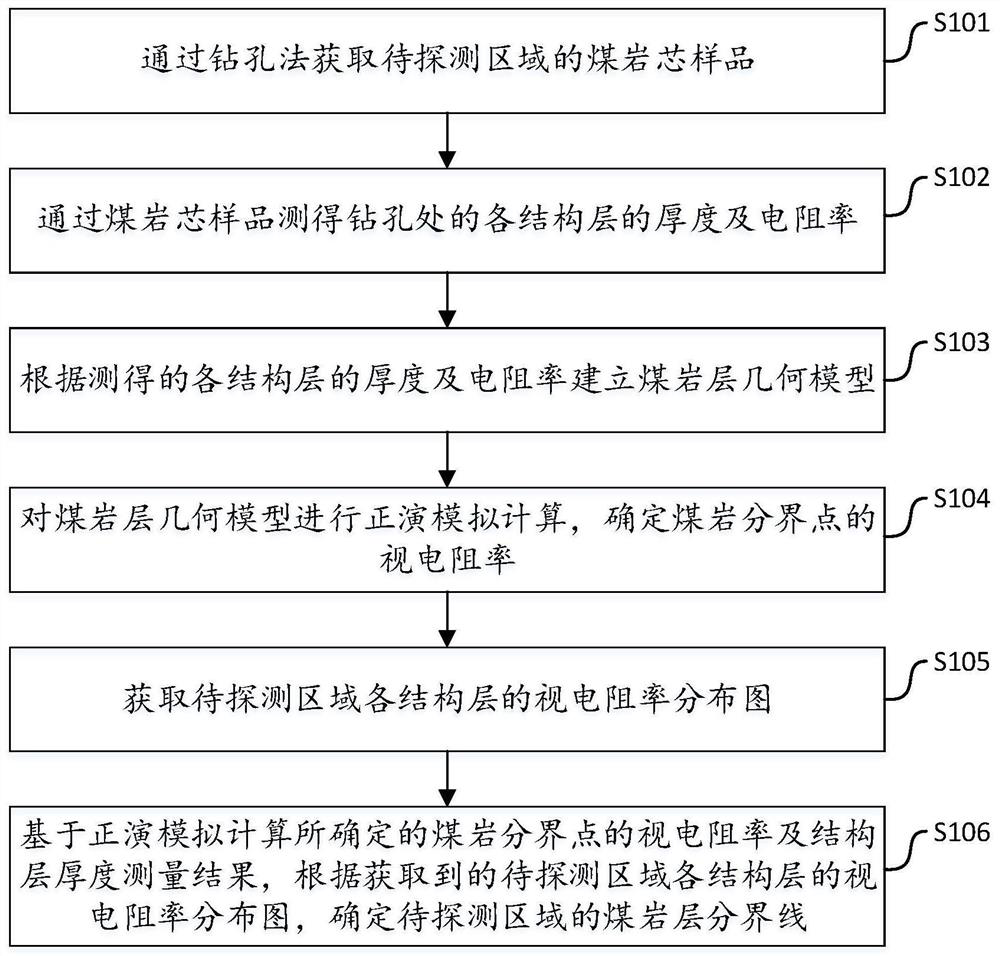

[0050] This embodiment utilizes the advantages of the direct current method for area detection to provide a method for quickly and accurately detecting the boundary of coal and rock layers, which is suitable for accurate determination of the position of the coal seam before mining the coal seam or when gas is extracted through the seam. The execution flow of the method for fast and accurate detection of coal-rock boundary is as follows: figure 1 shown, including the following steps:

[0051] S101, acquiring a coal core sample in an area to be detected by a drilling method.

[0052] Specifically, for the above steps, in this embodiment, according to the layout of the roof and floor roadways in the area to be detected, the bottom extraction roadway under the coal seam is selected as the test site; Drilling: obtaining coal core samples in the area to be detected through the through-bed drilling. Wherein, the length of the through-bed drilling is more than 20cm longer than the u...

no. 2 example

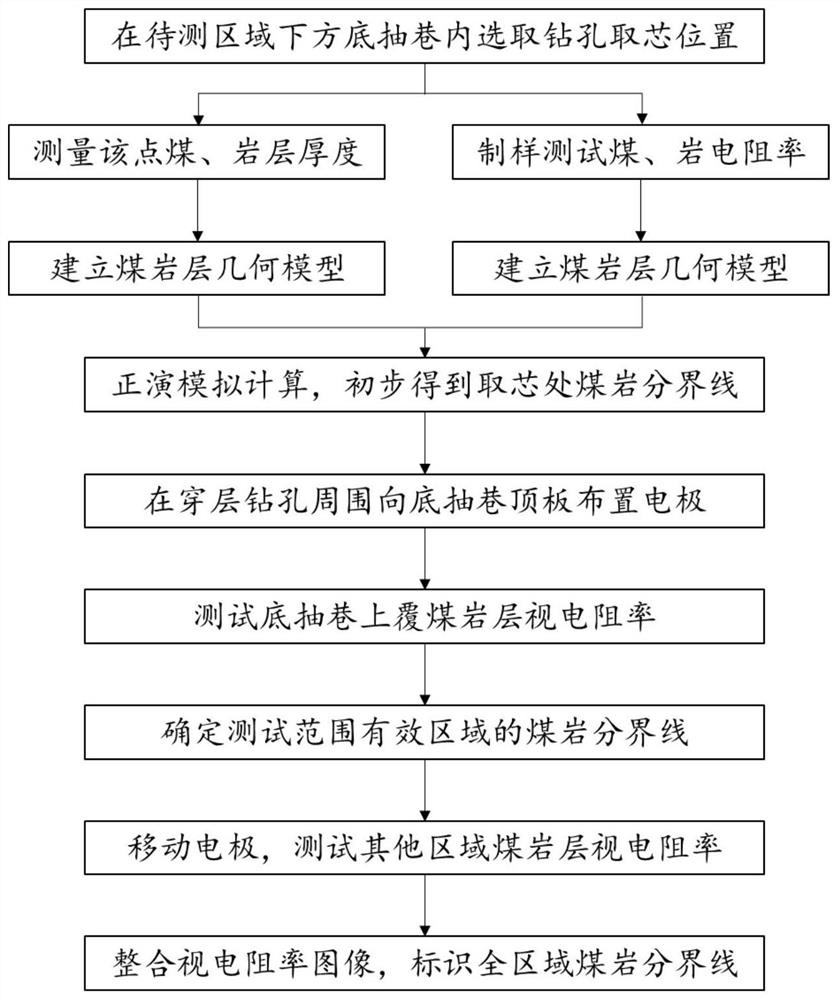

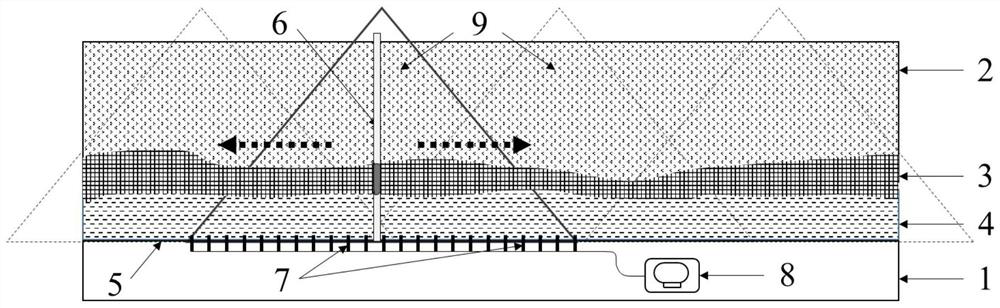

[0066] see figure 2 and image 3 , this embodiment provides a method for quickly and accurately detecting the boundary of coal and rock layers, which is suitable for accurately determining the position of the coal seam before mining the coal seam or during gas extraction through the seam. The method includes: constructing a layer-penetrating drilling hole on the roof of the bottom pumping roadway; taking cores to test the thickness and resistivity of the coal and rock formations, establishing a numerical model of the coal and rock strata, and performing forward simulation calculation of the apparent resistivity; obtaining the apparent resistivity of the bottom pumping roadway roof. Resistivity distribution map, combined with coring measurement, forward modeling and bottom roadway electrical test results, determine the boundary line of coal and rock layers within the test range; and obtain the boundary line of coal and rock layers in all areas to be tested by moving the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com