An LNG full-capacity storage tank stress analysis method under the wind load effect

A force analysis and wind load technology, applied in the field of force analysis of LNG full-capacity storage tanks, can solve problems such as storage tank damage, storage tank buckling deformation, and overturning, and achieve the effect of optimizing structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

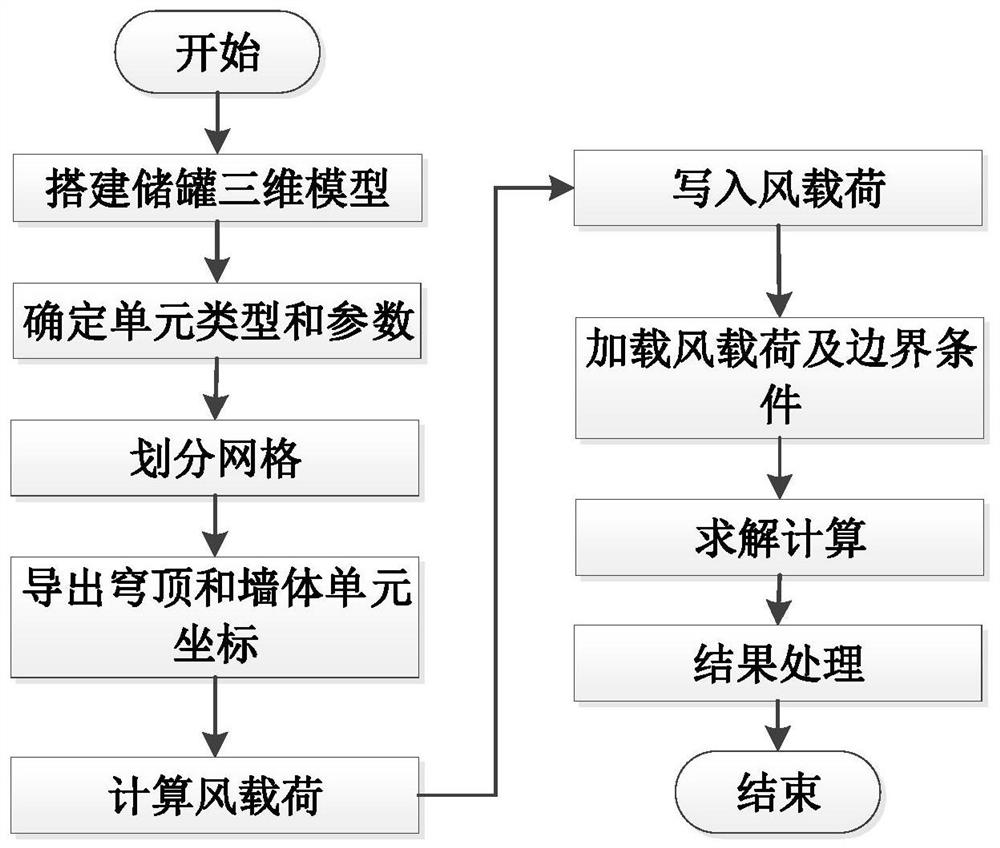

[0022] Examples such as Figure 1 to Figure 2 As shown, the present invention discloses a force analysis method for LNG full-capacity storage tank under the action of wind load, which is specifically carried out through the following steps:

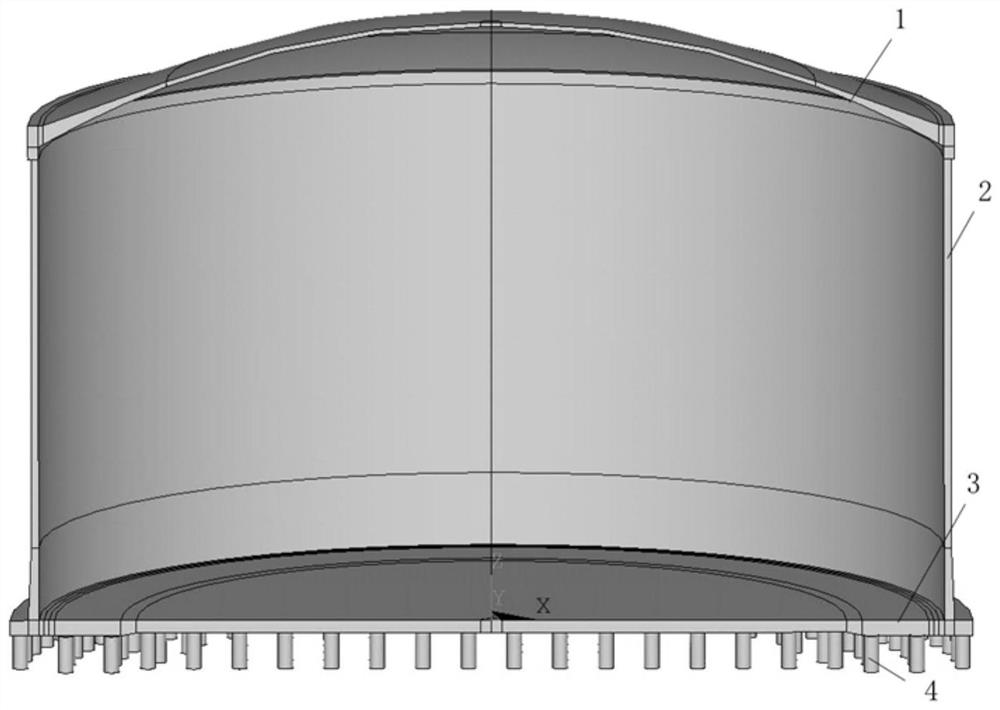

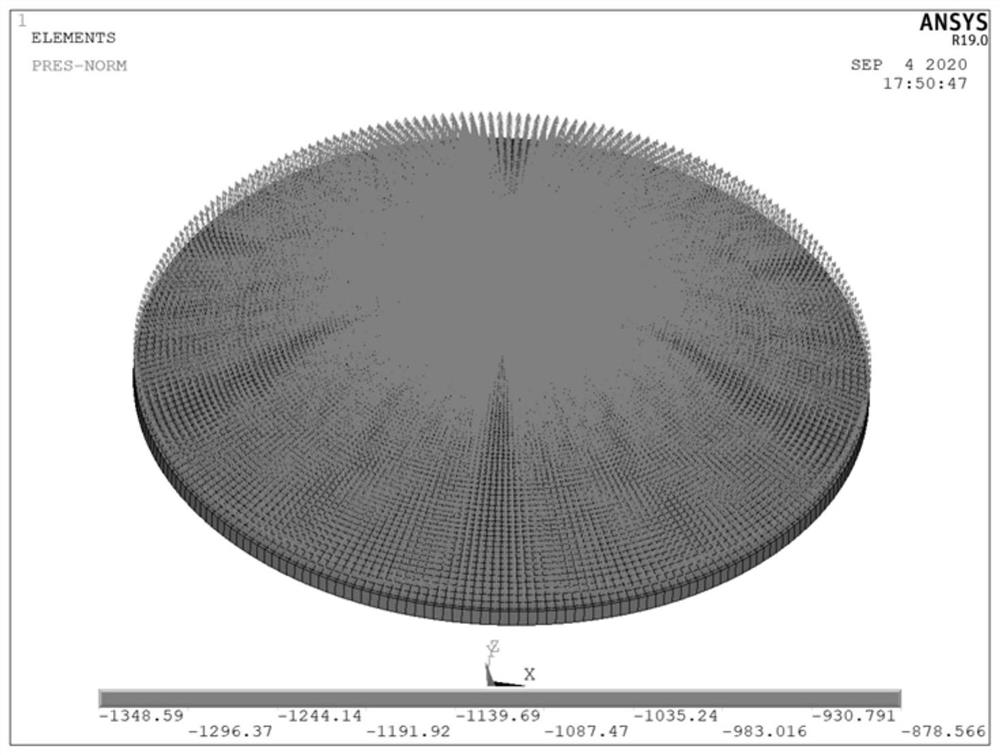

[0023] The specific operation of S1 is: based on the ANSYS APDL language, establish a three-dimensional refined geometric model of the LNG full-capacity storage tank, please refer to figure 2 . Use APDL language to only carry out 3D geometric modeling of the concrete structure of the concrete outer tank, including dome 1, wall 2, cap 3 and pile foundation 4; for storage tank dome 1, wall 2 and cap 3, use K in APDL language Commands define ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com