Panel structure for simulating gravel dam bursting test and manufacturing method of panel structure

A sand-gravel dam and a manufacturing method technology, applied in hydraulic models and other directions, can solve problems such as the great influence of the discharged water flow, irregular fractures, and difficulty in controlling cracks, so as to improve safety, improve structural design, and reduce casualties. and the effect of property damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

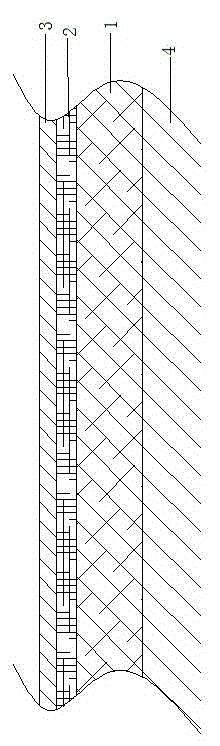

[0033] figure 1 It is a schematic diagram of the structure of the present invention. It can be seen from the figure that the present invention includes a veneer layer 1, a waterproof layer 2 and a protective layer 3, and the waterproof layer 2 is arranged between the veneer layer 1 and the protective layer 3. The slab 1 is pasted on the upstream surface of the simulated gravel dam 4 under test.

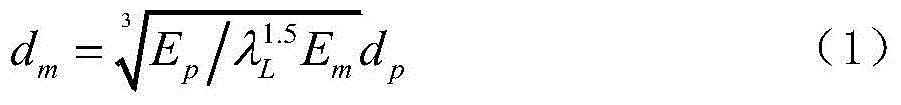

[0034] The material of the veneer layer 1 is a wood material, and the wood material used for making the veneer layer 1 is uniform in material, medium and thick wood fiber, straight in texture, with a rotational dry shrinkage rate of 3.8% to 4.1%, and a tree age of 30 to 35 years. year, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com