Process for regenerating a liquid absorbent

A liquid absorbent and process technology, applied in gas treatment, distillation separation, organic chemistry, etc., can solve problems such as performance loss and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

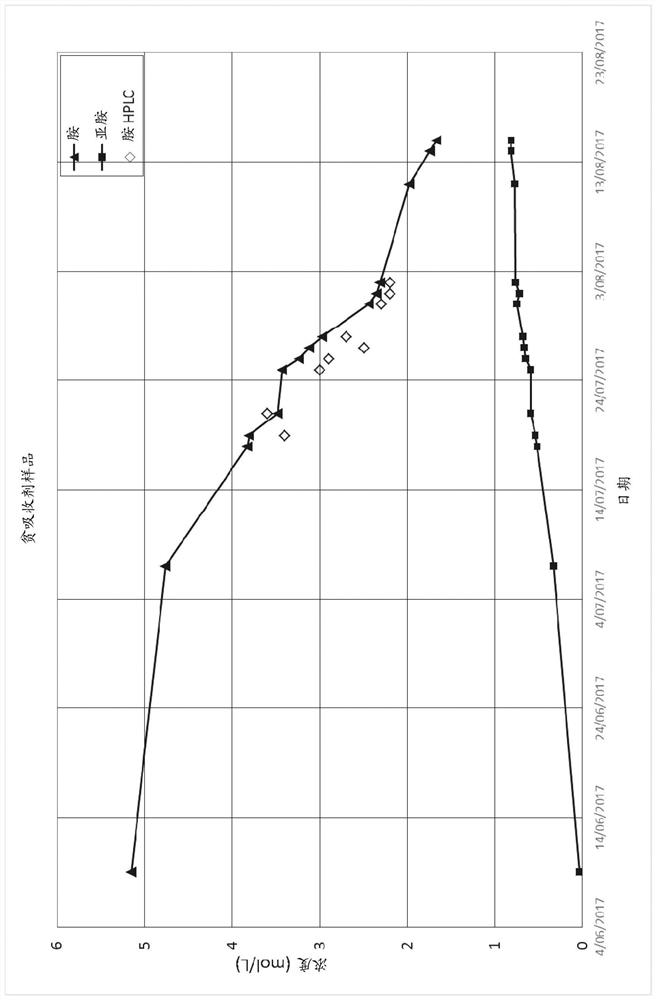

[0153] Example 1: Pilot Plant Trial Using an Aqueous Absorbent Containing 6 mol / L 3-AMPy

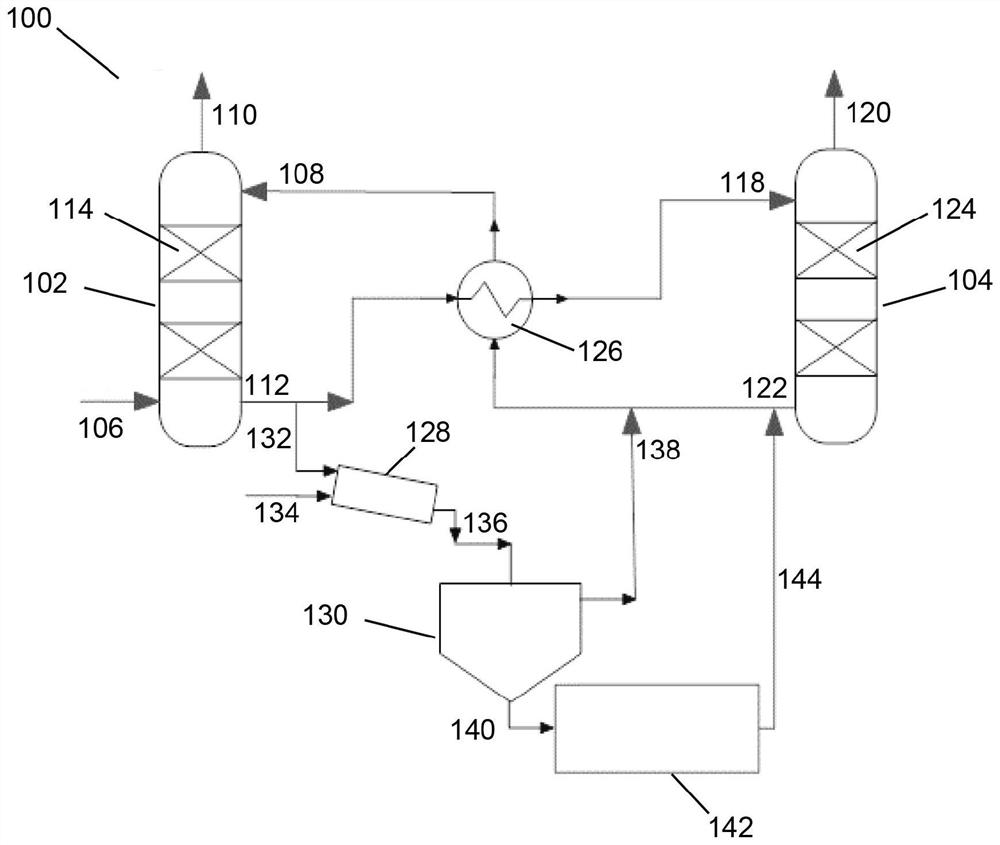

[0154] Already using 0.4 metric tons / day of CO located in lignite power stations 2 capture equipment for extended pilot plant testing, the CO 2 The capture device is configured with an absorption tower (102), a desorption tower (104) and a heat exchanger (126), generally as figure 1 depicted in . Capture equipment to take 80m directly from the power station 3 / h flow of flue gas slipstream operation.

[0155]Exercise using 6 mol / L of aqueous 3-AMPy (61 wt% 3-AMPy and 39 wt% water) was operated for a duration of approximately 1500 hours (63 days). During operation, the performance of the plant was evaluated in terms of reboiler energy requirements and amine degradation was monitored. A single major degradation product formed was also identified and characterized. Achieved 2.9GJ / metric ton of CO without and with cold-rich split process configurations, respectively 2 and 2.6GJ / metric...

Embodiment 2

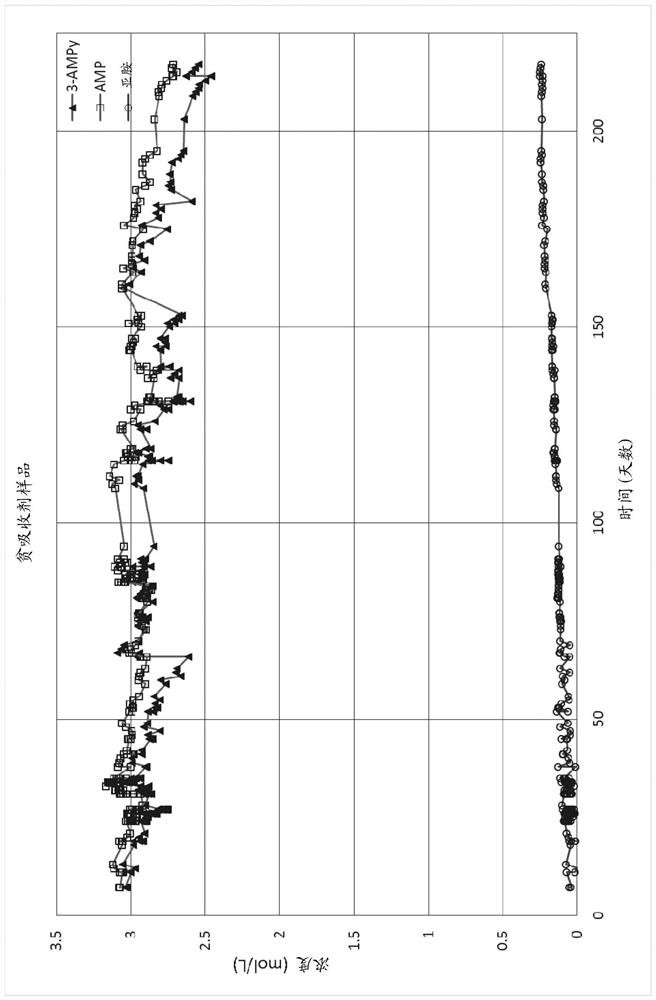

[0160] Example 2. Pilot plant test using an aqueous absorbent comprising 3 mol / L of 3-AMPy and 3 mol / L of AMP

[0161] Based on the degradation mechanism of the above scheme, it is considered that if 3-AMPy is formulated with a stronger base to reduce the 2 formation of protonated 3-AMPy during absorption, its degradation can be inhibited. 2-Amino-2-methyl-1-propanol (AMP) was chosen as the amine for formulation due to its required basicity and known 2 Capture applications are robust. AMP does not interact with CO 2 reacts directly, but acts as a base to preferentially accept the protons released when 3-AMPy reacts. Simulations indicated that the concentrations used in aqueous absorbents of 3 mol / L 3-AMPy and 3 mol / L AMP were optimal for reducing degradation and maintaining capture performance.

Embodiment 3

[0164] Example 3. Comparison of the absorbents of Examples 1 and 2 with MEA

[0165] The pilot plant was also operated with 5 mol / L (30 wt%) aqueous monoethanolamine (MEA) for approximately 500 hours. This allows determining the optimal reboiler duty for each absorbent via parametric studies. These optimum reboiler duty and amine degradation rates are shown in the table below and are for the standard plant configuration (no rich split). It should be noted that the MEA degradation information was obtained from the literature, since the MEA was only run for short durations in the pilot plant.

[0166]

[0167] *Degradation rate obtained from the book P. Feron, Absorption-Based Post-Combustion Capture of Carbon Dioxide, Elsevier (2016).

[0168] Oxidative degradation of monoethanolamine is known to produce organic acids (such as formic and oxalic acids) and a wide variety of other products, many of which are highly soluble in aqueous absorbent solutions. The degradation pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com