Chain tensioner

A technology of tensioner and locking part, applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., can solve problems such as chain tensioner failure, engine failure, etc., and achieve the effect of preventing non-action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

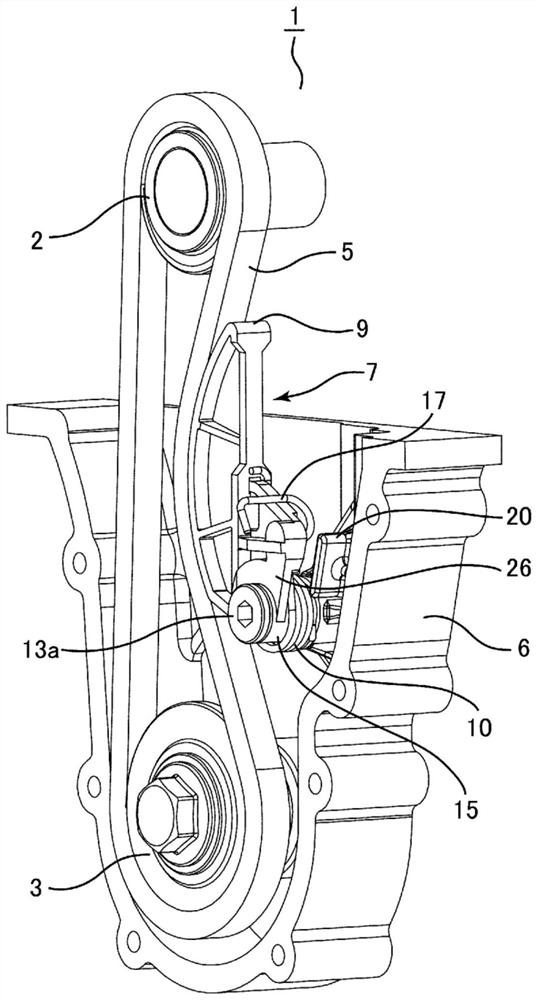

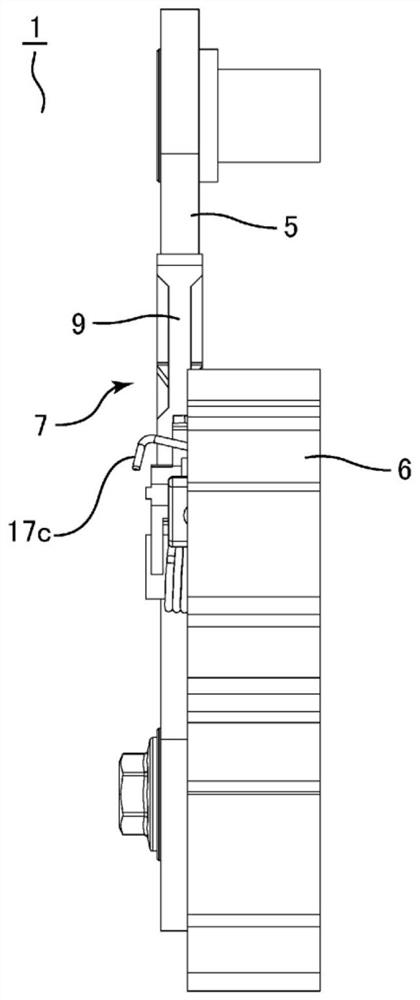

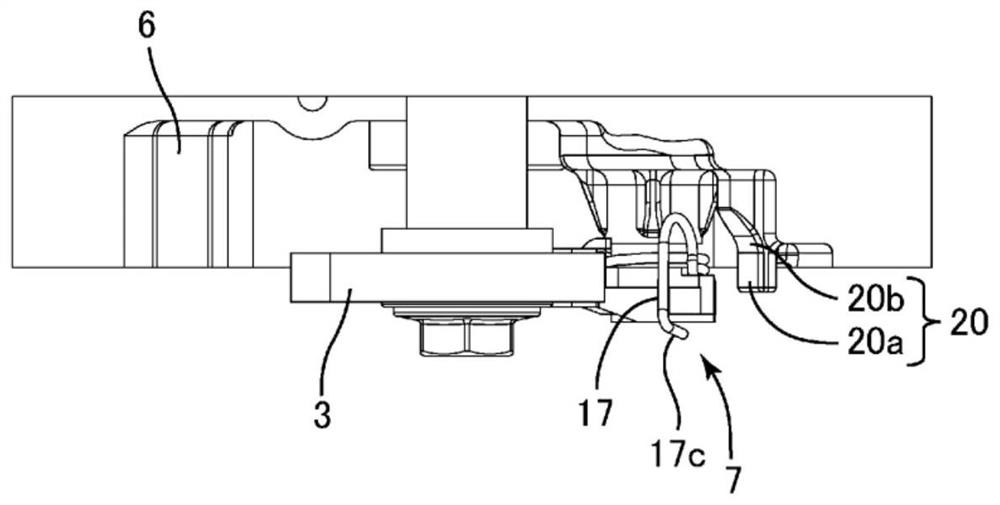

[0062] Embodiments of the present invention will be described below with reference to the drawings. Such as Figure 1 ~ Figure 2B As shown, the chain transmission device 1 of this embodiment has a driving side sprocket 2 linked with the engine crankshaft, a driven side sprocket 3 linked with auxiliary machines such as an oil pump and a balancer, and a sprocket 3 wound around these two chains. Chain 5 for wheels 2,3. The chain 5 is usually a roller chain, but may be other chains such as a silent chain. The chain transmission 1 is accommodated in a chain case 6 constituted by an engine block, and a chain tensioner 7 is arranged in the chain case 6 .

[0063] Such as Figure 3A ~ Figure 3D As shown, the chain tensioner 7 has a rod (arm) 9 that is in sliding contact with the slack side of the chain 5, and a twisted screw that is compressed between the rod and the chain case 6 and acts a predetermined force on the rod 9. spring 10. also, Figure 1 ~ Figure 3D The state shown ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap