Anti-overlap valves for rail vehicle foundation brakes

A technology for a basic braking device and a rail vehicle, which is applied in the field of anti-overlapping valves, can solve the problems of accelerating the wear of parts of the basic braking device, affecting the service life of the basic braking device, and the phenomenon of train sliding, and achieves a simple structure and avoids overlapping. , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

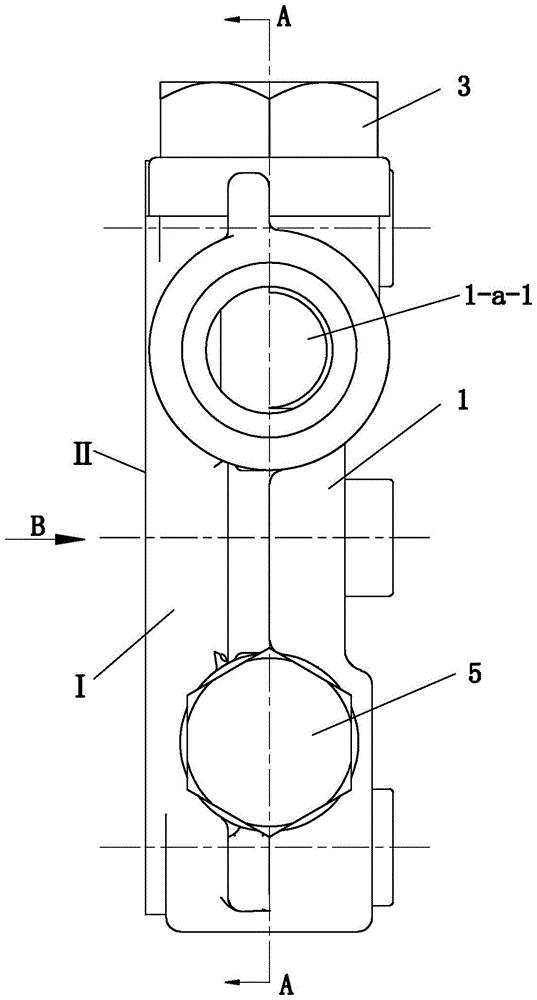

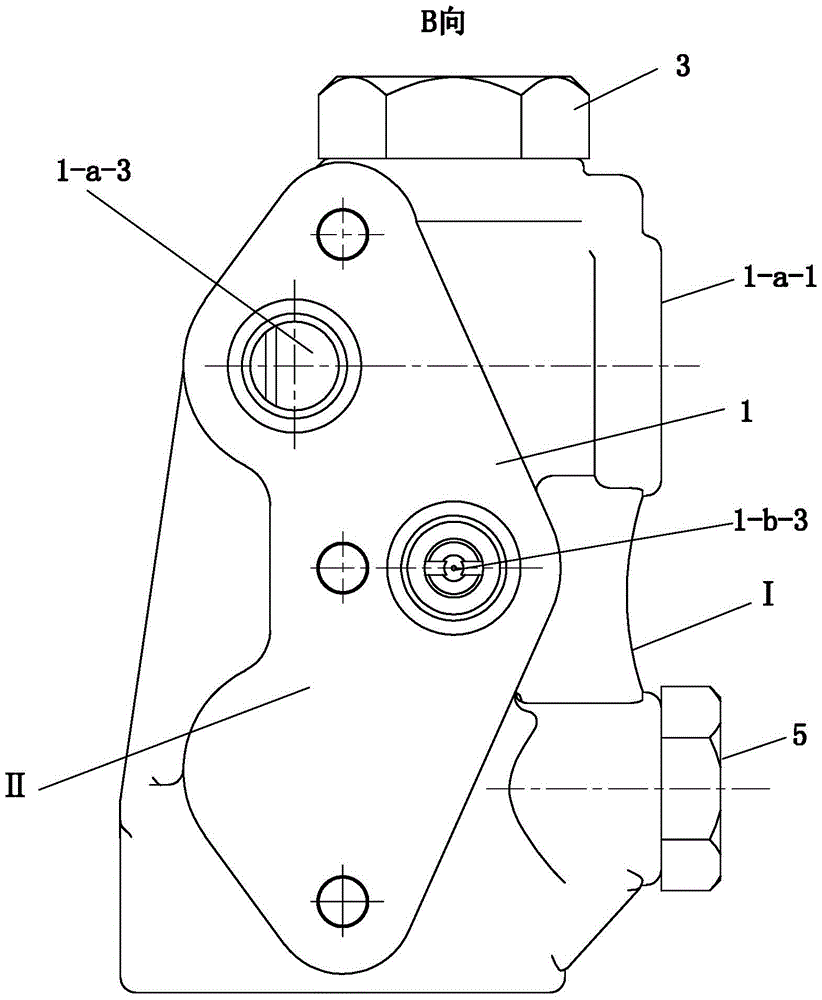

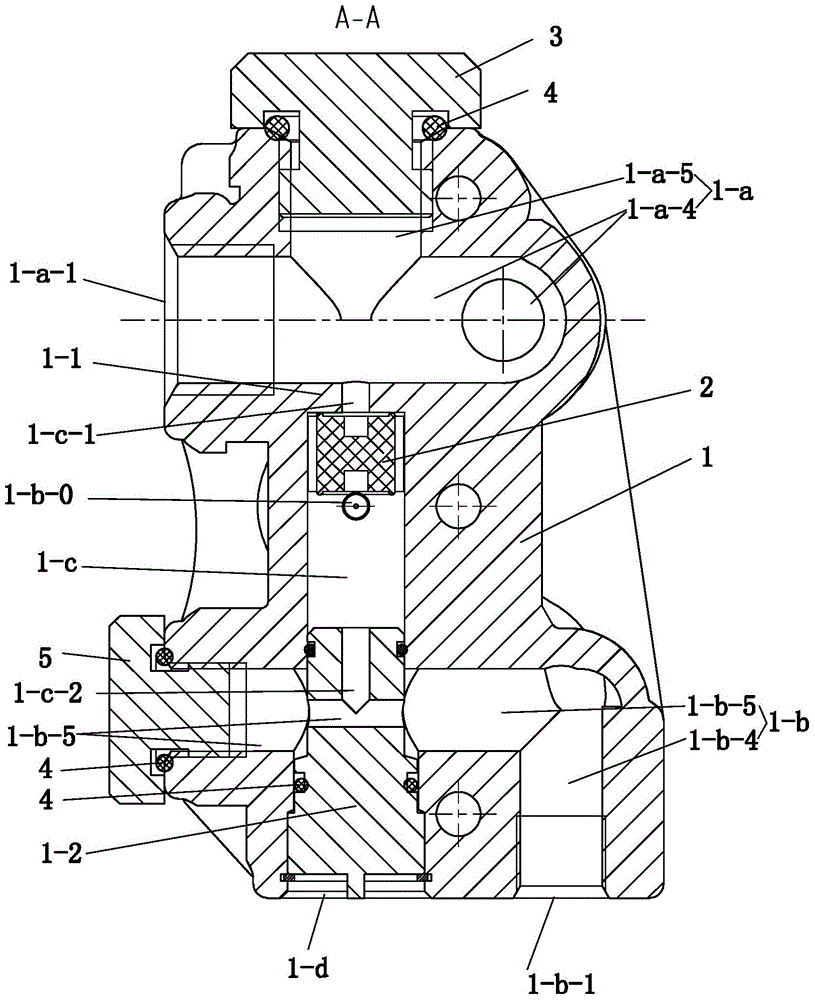

[0022] Front, back, left, right, up, down in this article figure 1 prevail.

[0023] See Figure 1 to Figure 4 and Image 6 , The present embodiment has a valve body 1, and the valve body 1 is provided with a slider cavity 1-c, a common brake air supply channel 1-a and a parking brake air supply channel 1-b. Both the common brake air supply channel 1-a and the parking brake air supply channel 1-b are connected with the slider cavity 1-c, and the valve body is provided with a parking brake supply channel in the middle of the slider cavity 1-c. Gas extension to 1-b-0. A slider 2 is provided in the slider chamber 1-c.

[0024] There is a first bottom hole 1-d on the bottom surface of the valve body 1, and the first bottom hole 1-d is blocked by a post plug 1-2 to form a slider cavity 1-c on its upper part, and the first bottom hole 1- A sealing ring 4 is provided between the orifice of d and the plug 1-2. The column plug 1-2 is regarded as a part of the valve body.

[0025...

Embodiment 2

[0041] See Figure 5 , in this embodiment, the second air inlet 1-a-2 of the common brake air supply passage 1-a takes in air, and the first air inlet 1-a-1 is blocked by the upper screw plug 3, which is blocked A sealing ring 4 is provided between the opening of the upper screw plug 3 and the upper screw plug 3. The second air inlet 1-b-2 of the parking brake air supply channel 1-b takes in air, and the first air inlet 1-b-1 is blocked by the lower screw plug 5, and the blocked hole and the lower screw A sealing ring 4 is arranged between the plugs 5 . All the other are identical with embodiment 1.

Embodiment 3

[0043] This embodiment omits the view. In this embodiment, the second air inlet 1-a-2 of the common brake air supply channel 1-a is used for air intake, and the first air inlet 1-a-1 is blocked by the upper screw plug 3. Note that the parking brake air supply channel 1-b uses the first air inlet 1-b-1 to inhale air, and the second air inlet 1-b-2 is blocked by the lower screw plug 5.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap