Electrically heated catalytic combustor

A catalytic burner, electric heater technology, applied in the direction of combustion chamber, combustion equipment, combustion method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

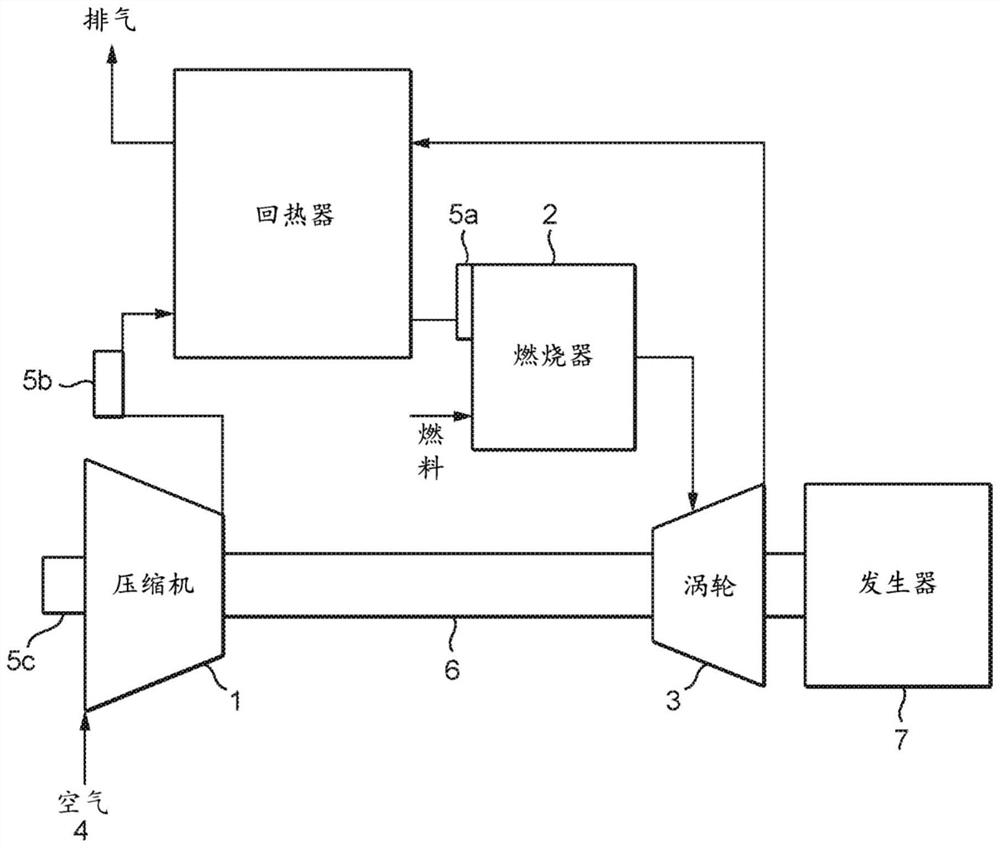

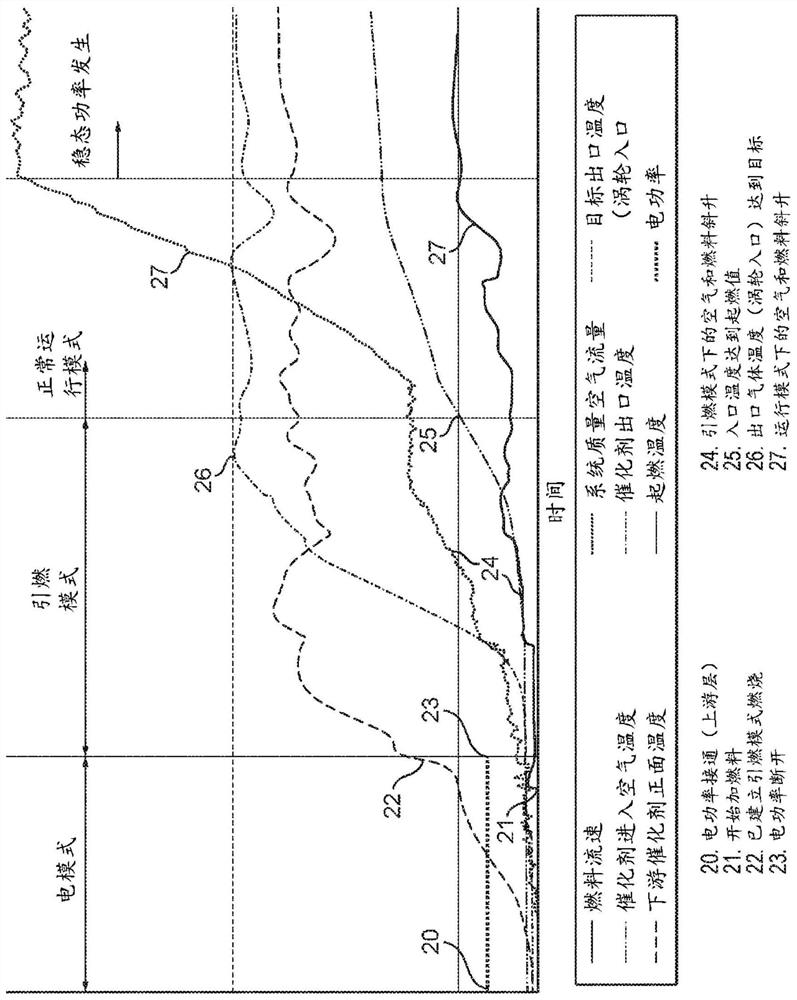

[0115] Implementation 1 A system comprising a regenerative gas turbine engine having a catalytic combustor comprising:

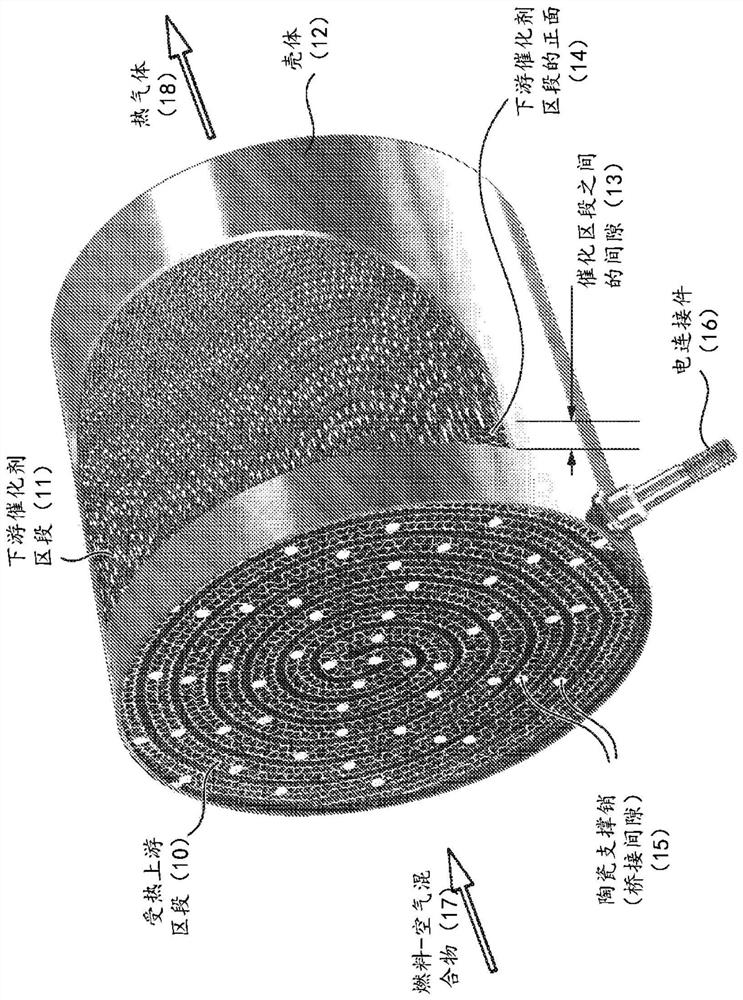

[0116] (a) an upstream section comprising an electric heater, and

[0117] (b) A downstream catalyst section, wherein the upstream section and the downstream catalyst section are disposed adjacent to each other and in fluid communication.

[0118] In certain aspects of this embodiment, a spacer is included between the upstream section and the downstream catalyst section; in other aspects, the two sections are in physical contact with each other; air gap. This air gap can be important to avoid short circuits in the metal substrate. For combined metal-ceramic substrates, it is possible to avoid discrete "interlayer gaps" across the diameter of the catalyst. In other aspects, there may also be a ceramic insulating connection between two segments constituting a physical support with electrical insulation.

Embodiment approach 2

[0119] Embodiment 2 The system of embodiment 1, wherein the upstream section including the electric heater is the only source of ignition in the catalytic combustor. In independent aspects of this embodiment, some embodiments have and do not have a separate ignition source, but preferably there are no ignition sources other than electric heaters. In other respects, the system does not contain additional igniters anywhere in the system.

Embodiment approach 3

[0120] Embodiment 3 The system according to embodiment 1 or 2, wherein the upstream section and the downstream catalyst section are integrated in a single unit. In certain independent aspects of this embodiment, the two sections are compositionally identical or different from each other due to the substrate material or catalyst material contained within each section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com