Method and system for calculating storage energy field of steady-state cutting first deformation area

A calculation method and technology of deformation zone, applied in the field of machining, can solve problems such as many characteristic parameters and complex research process, and achieve the effect of clear explanation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

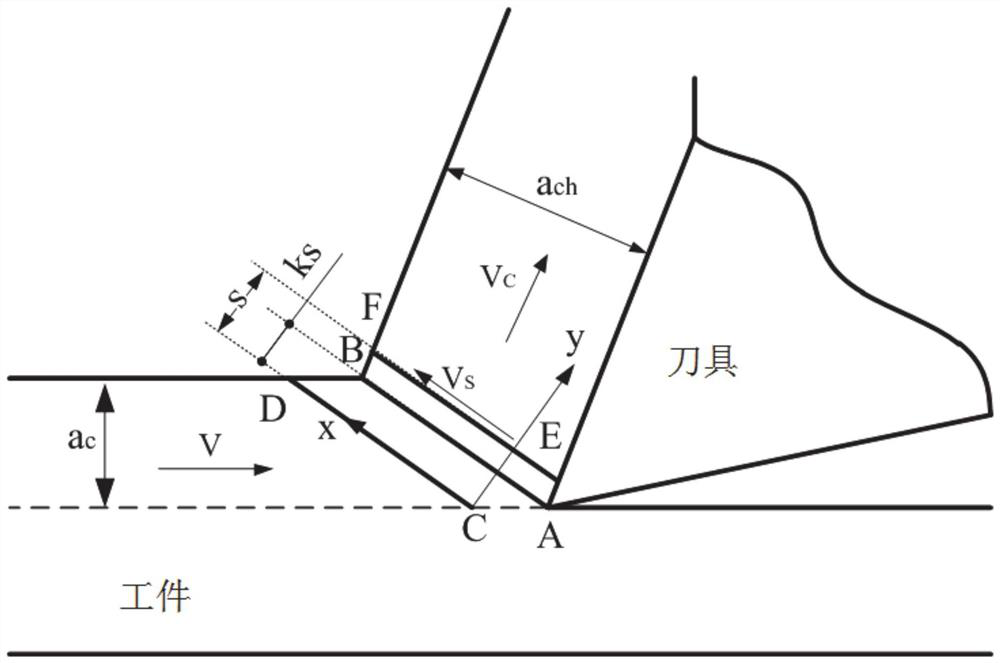

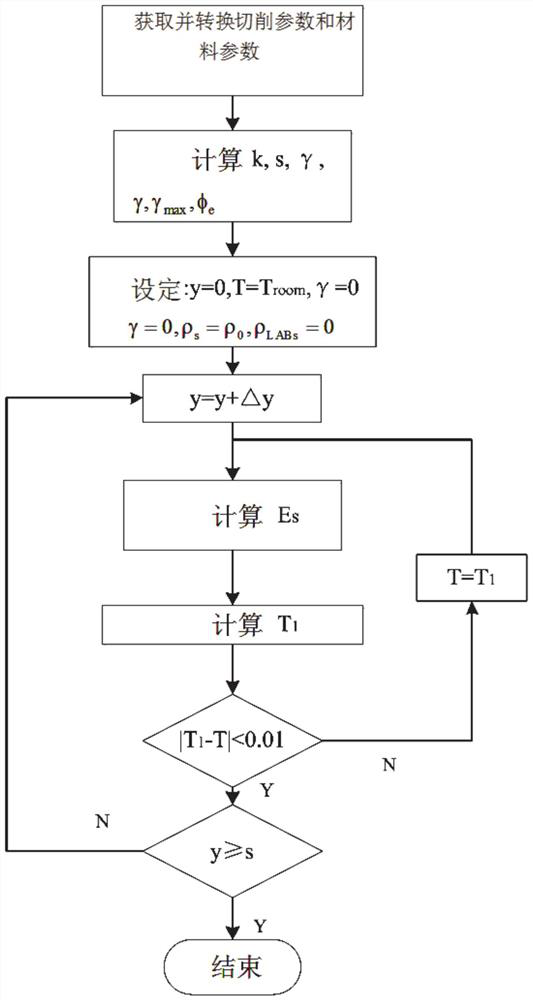

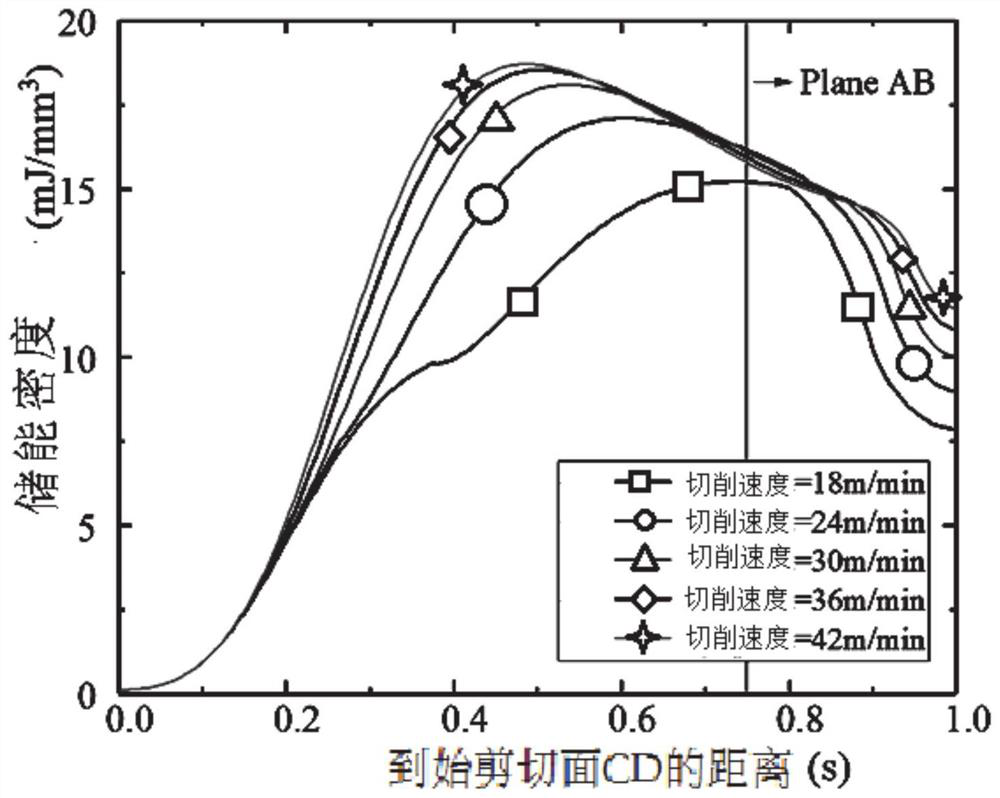

[0033] In a typical implementation of the present invention, this embodiment discloses a calculation method for the stored energy field in the first deformation zone of steady-state cutting, including the following steps:

[0034] (1) Fit the parameters of the storage energy evolution model of the workpiece material based on the stress-strain curves of the workpiece material under different deformation conditions, and the model is related to temperature, strain, and strain rate. Stored energy E s The dislocation density ρ total means, that is:

[0035] E. g =αμb 2 ρ total / χ

[0036] Among them, α is the dislocation interaction parameter, which is 0.5; μ is the shear modulus of the material; b is the value of the Burgers vector; χ is the proportional coefficient considering the alloy elements, which is 0.6. Therefore, the establishment of the storage energy evolution model depends on the dislocation density evolution model, which can be divided into statistical storage d...

Embodiment 2

[0142] In a typical implementation of the present invention, this embodiment discloses a calculation system for storing the energy field in the first deformation zone of steady-state cutting, including:

[0143] Fitting unit, microelement generation unit and conversion unit, the fitting unit is used to fit the storage energy evolution model of the material, the microelement generation unit is used to divide the microelement in the first deformation zone; the conversion unit is used to convert the three-dimensional cutting model into 2D cutting model;

[0144] The solving module is used to receive the data output by the fitting unit, the micro-element generation unit and the conversion unit, calculate the strain and strain rate of each micro-element and analyze the temperature of each micro-element according to the output data of the conversion unit, and analyze the temperature of each micro-element according to the output data of the fitting unit The storage energy evolution m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com