Polishing powder spraying device for electronic display screen polishing and implementation method of polishing powder spraying device

A technology of spraying device and display screen, which is used in surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of easily damaged display screen, backward polishing materials, and inability to be clearly and simply observed by the naked eye. , to achieve the effect of reducing power equipment and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0034] In order to better demonstrate the polishing powder spraying process, this embodiment shows the implementation method of the polishing powder spraying device for polishing electronic display screens, including the following steps:

[0035] Step 1: the delivery pipe 44 is connected to the box for storing polishing powder, and the valve on the delivery pipe 44 is in a closed state;

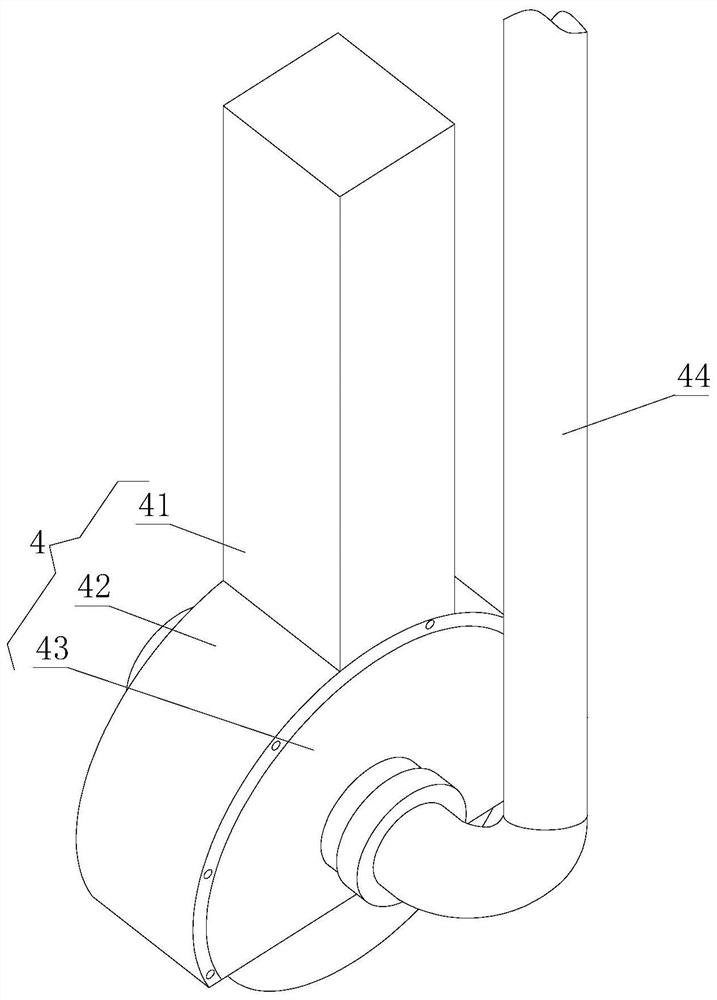

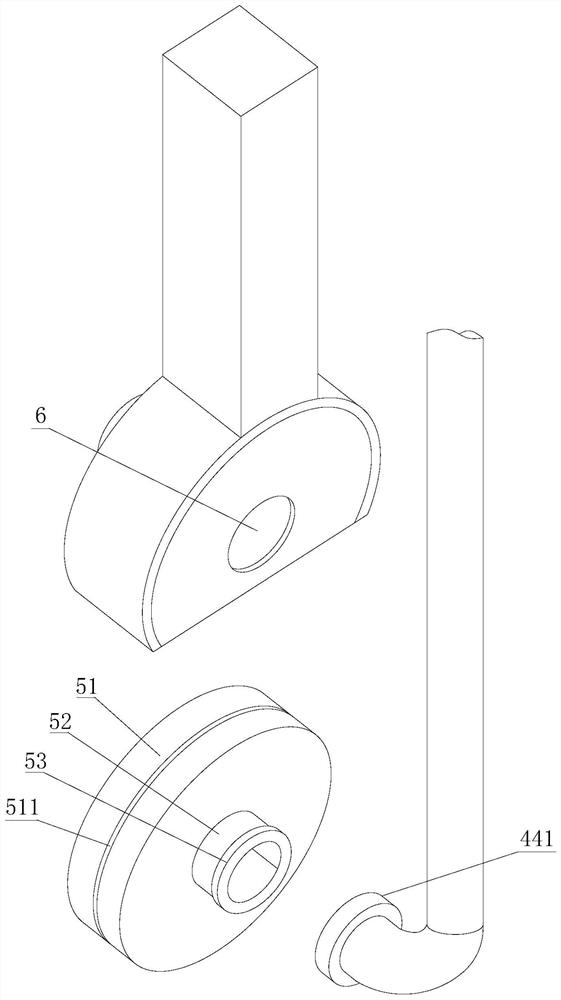

[0036] Step 2: Place the display screen body 3 on the pallet frame 2 for clamping and fixing, press the button 451, the block 455 retracts into the guide sleeve 454, the interface 441 is set on the main shaft 52, and the button 451 releases the block 455 to pass through The interface 441 is against the collar 53;

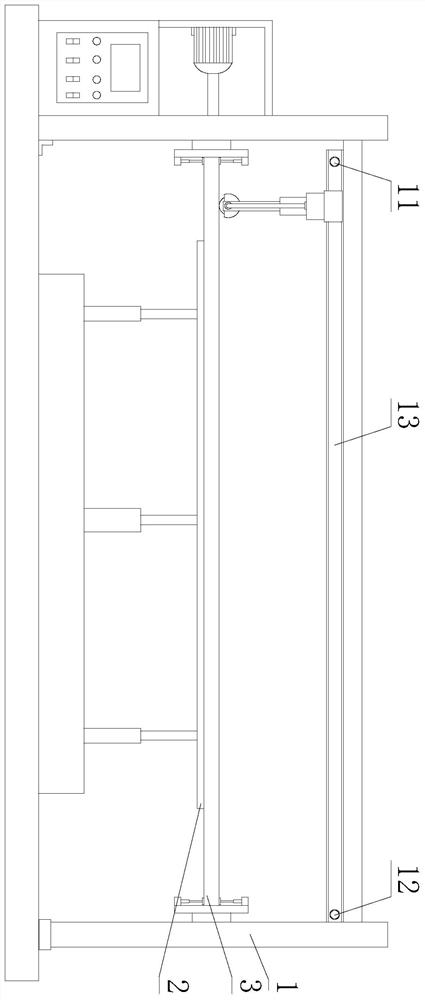

[0037] Step 3: While the slide rail 13 moves along the screw rod 11, the support frame 41 moves along the slide rail 13, and the polishing wheel 51 polishes the surface of the display body 3 in an "S" shape;

[0038] Step 4: The main shaft 52 drives the side plate 56 and the polis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap