A Deformation Quality Detector for Railway Tracks

A railway track and detector technology, which is applied to railway vehicle shape measuring instruments, railway inspection cars, railway car body parts, etc., can solve problems such as track deformation detection errors, and achieve the effect of reducing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

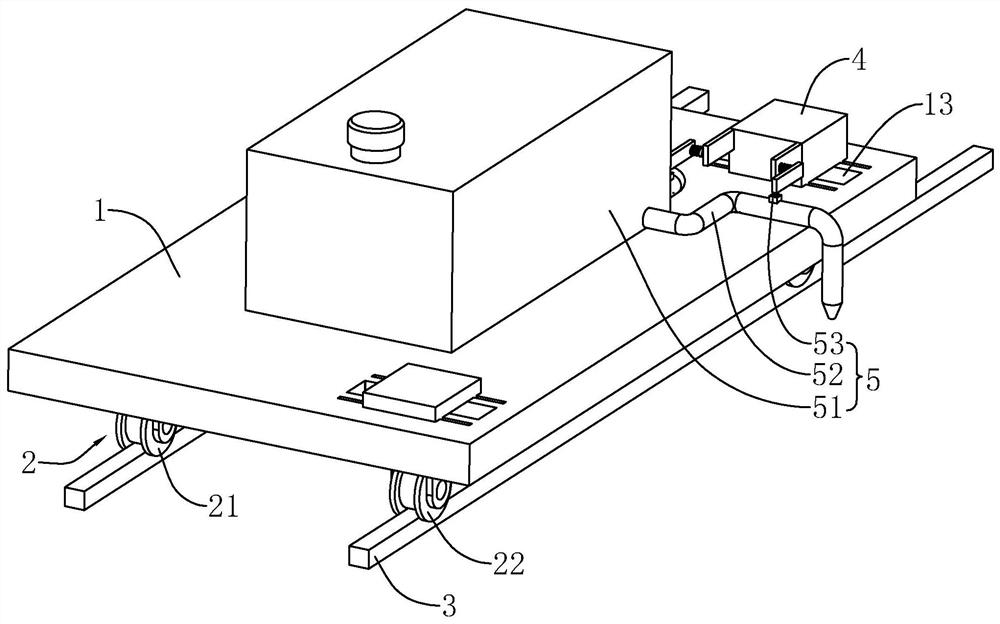

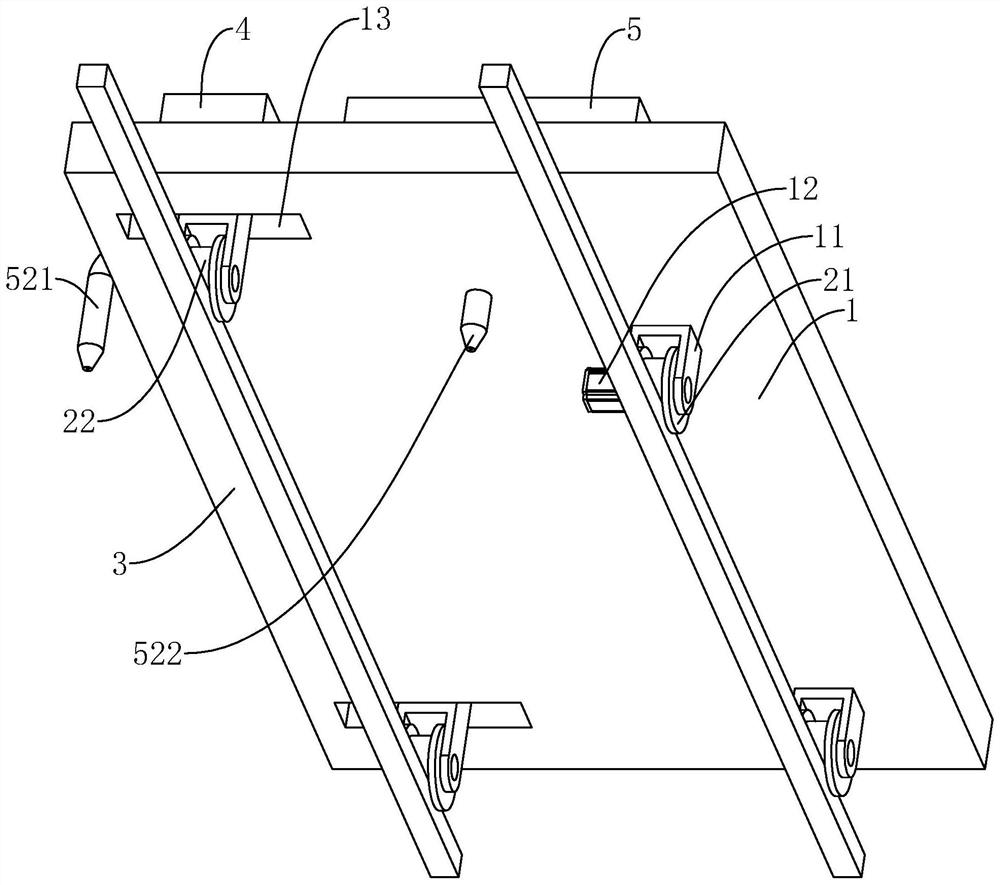

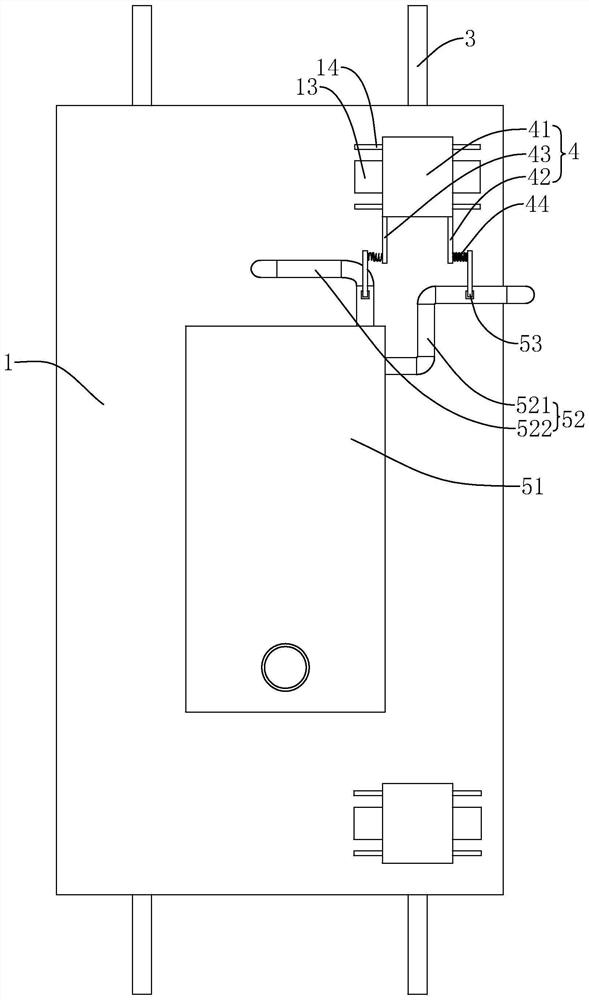

[0040] Attached to the following Figure 1-5 This application will be described in further detail.

[0041] The embodiment of the present application discloses a railway track deformation quality detector, which is used to detect the deformation quality of a linear guide rail.

[0042] refer to figure 1 , a kind of measuring instrument for railway track deformation quality includes a trolley 1, a plurality of rollers 2 rotatably connected to the bottom of the trolley 1, and two tracks 3 are arranged below the rollers 2. The roller 2 includes a fixed pulley 21 that rotates on one of the tracks 3, and a movable pulley 22 that rotates on the other track 3. The movable pulley 22 is provided with a detection component 4 for detecting the bending of the track 3, and a detection component 4 is installed on the trolley 1 after detection. Marking component 5 for timely marking,

[0043] refer to figure 2 , the bottom of the trolley 1 is fixedly connected with the outrigger 11 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com