Building machine and construction method for house building ground foundation engineering construction

A foundation engineering and foundation technology, applied in the direction of foundation structure engineering, construction, sheet pile wall, etc., can solve the problems of reducing piling effect, piling, pile shaft can not be straight, etc., and achieve the effect of improving piling effect and improving adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

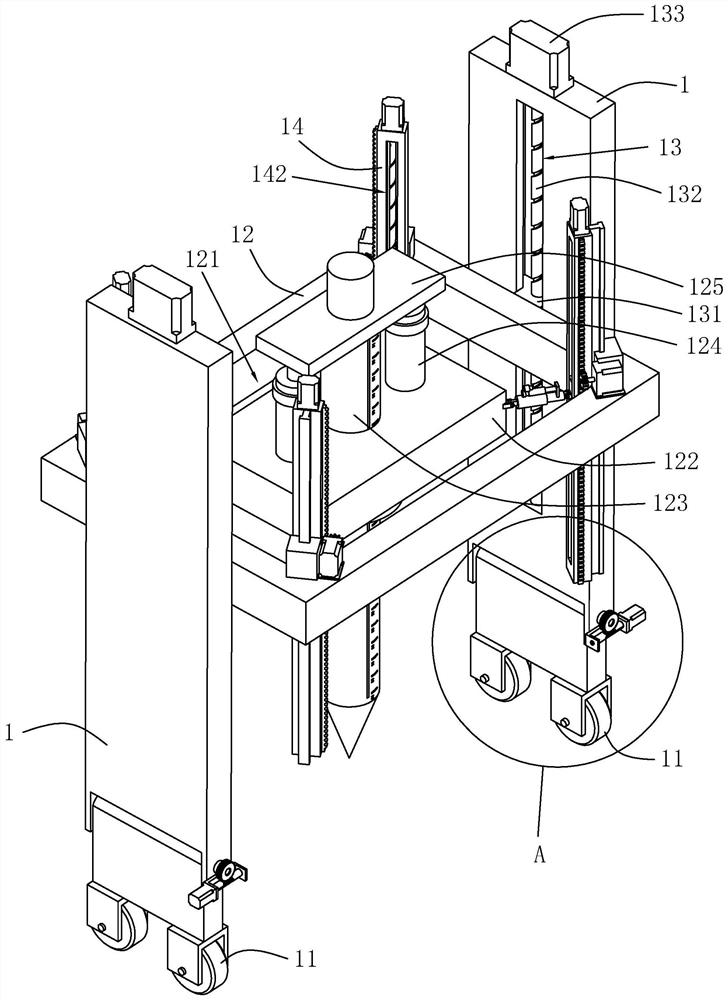

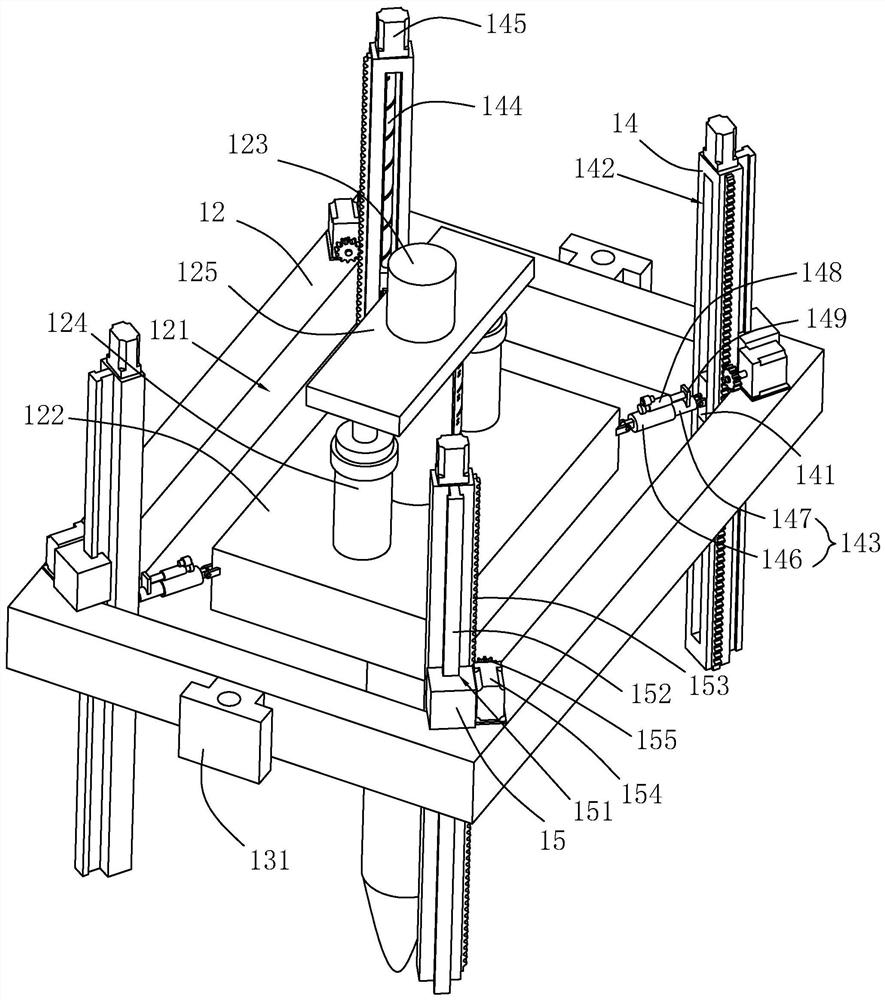

[0037] The following is attached Figure 1-3 The application is described in further detail.

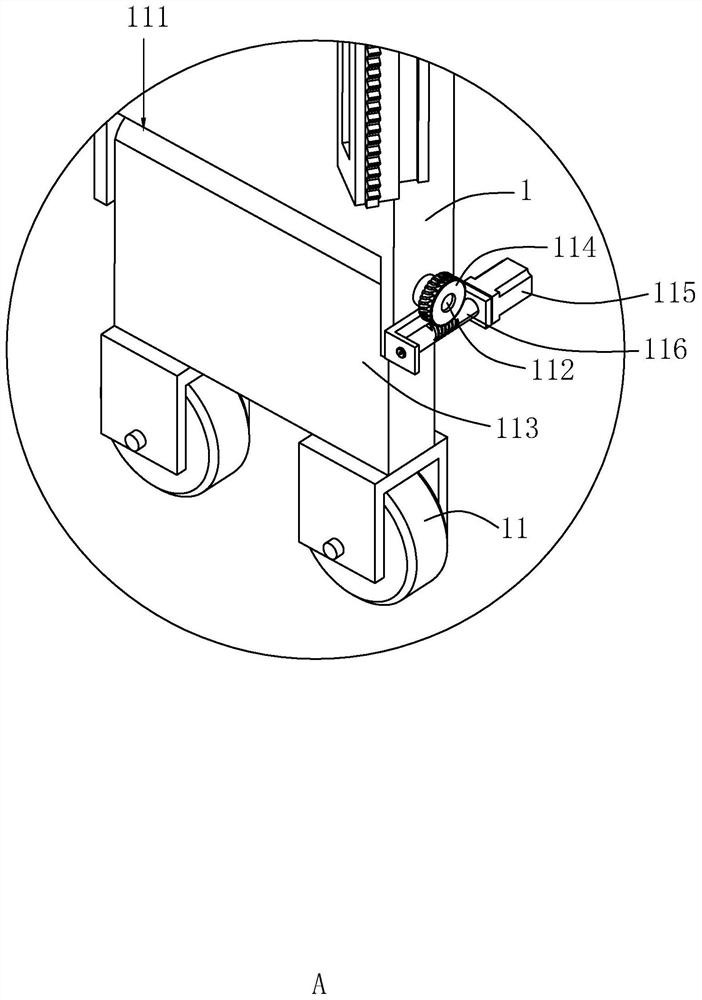

[0038] The embodiment of the present application discloses a construction machine for house foundation foundation engineering. refer to figure 1 , a construction machine for house foundation foundation engineering, comprising columns 1 arranged parallel to each other and at intervals, rollers 11 are installed at the same end of the columns 1 on both sides, and plates are arranged across the columns 1 on both sides 12. An adjustment opening 121 is opened in the middle of the plate body 12, and an adjustment plate 122 is arranged across the inside of the adjustment opening 121. The adjustment plate 122 is pierced and slidably connected with a pile rod 123. The adjustment plate 122 is provided with a pile rod 123 for driving The drive mechanism that moves back and forth on the adjustment plate 122; in this embodiment, the drive mechanism is set as a reciprocating cylinder 124 that is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com