Foundation pit deformation monitoring device

A deformation monitoring and foundation pit technology, which is applied in foundation structure engineering, foundation structure testing, construction, etc., can solve the problem of continuous monitoring of cracks in foundation pit support structures, high work intensity, and difficult comprehensive and accurate real-time monitoring And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

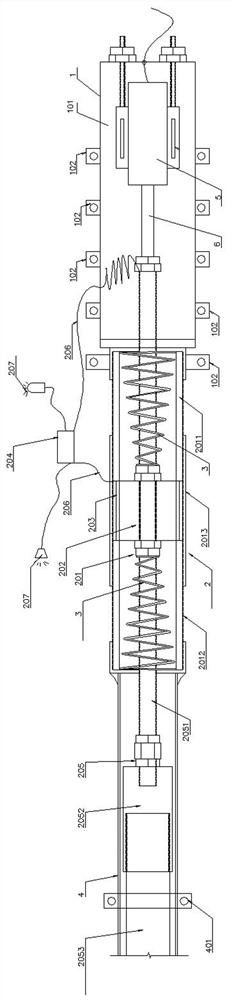

[0015] Embodiment 1: as figure 1 As shown, the present invention includes a fixed end 1, a monitoring member 2 arranged on the fixed end 1, the fixed end 1 includes a fixed end bracket 101, a fixed terminal 102 arranged on the periphery of the fixed end bracket 101, and the monitoring structure 2 includes a screw thread or The cylindrical object 201 fixed on the fixed end bracket 101 of the fixed end 1 by welding, the columnar conductive slider 202 slidably arranged in the cylindrical object 201, the conductive ring 203 arranged in the middle of the inner cavity of the cylindrical object 201, and the detection The control device 204, the end of the conductive slider 202 away from the fixed end 1 is connected with a detection rod 205, the conductive ring 203 and the conductive slider 202 are connected to the detection control device 204 through a wire 206, and the detection control device 204 controls the alarm (acousto-optic alarm) 207 work.

[0016] Preferably, the barrel 20...

Embodiment 2

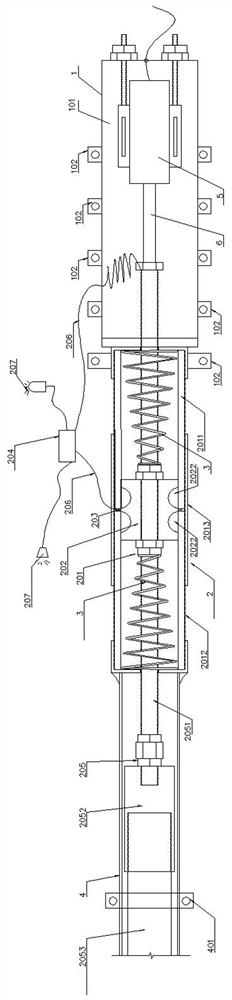

[0021] Embodiment 2: as figure 2 As shown, this embodiment is based on Embodiment 1. The middle part of the conductive slider 202 is a detection section 2021 , and the conductive slider 202 on both sides of the detection section 2021 is provided with grooves 2022 . Using the groove 2022, when the required detection section 2021 is short, the monitoring of the maximum deformation of the object to be monitored in the foundation pit can be realized through the groove 2022, and at the same time, it does not affect the conductive slider 202 outside the groove 2022 Guided by other parts of the cylinder, it slides smoothly in a straight line in the barrel 201.

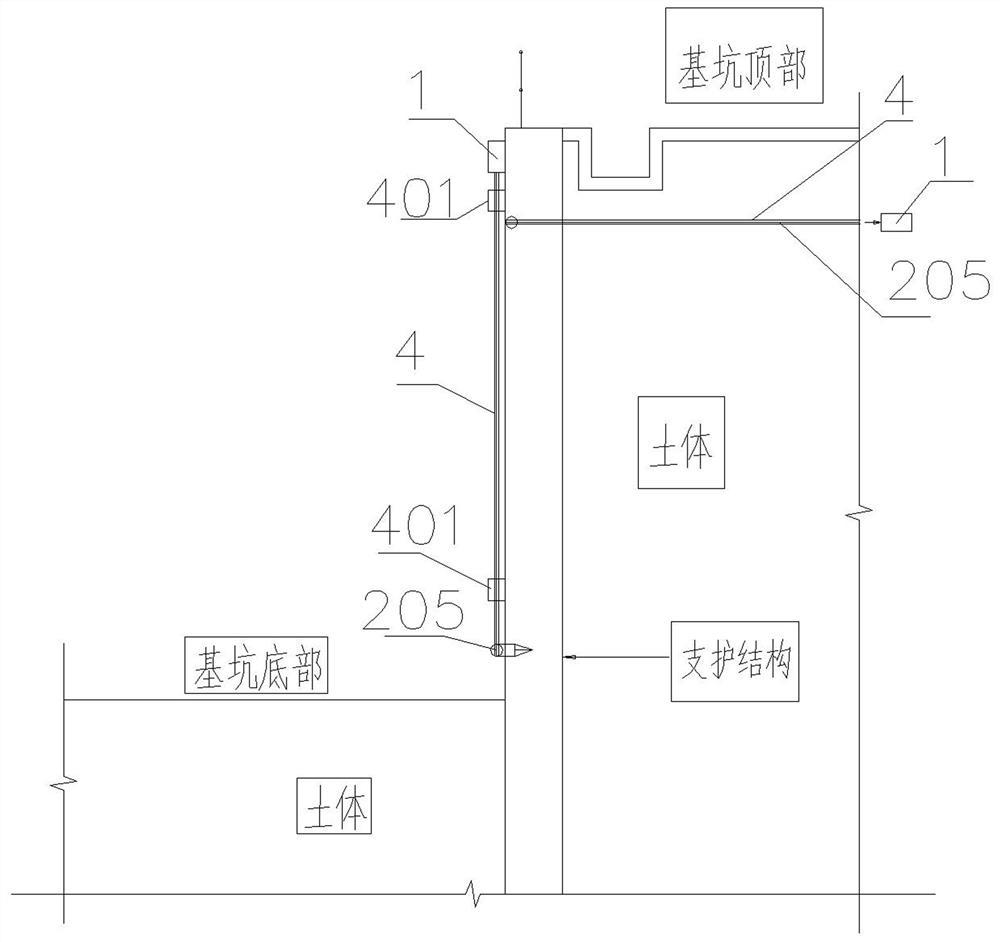

[0022] Such as image 3 , 4 As shown, when in use, the fixed end 1 is fixed at the place where the support of foundation pit A is relatively small in deformation (inner corner, support node, etc.), and the far end of the detection rod 205 is fixed at a certain distance (the outer corner of the foundation pit, across differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com