Multifunctional tunnel supporting pointed machine

A multifunctional and tunnel technology, applied in maintenance and safety accessories, metal processing machinery parts, metal processing, etc., can solve problems such as poor circulation, reduced service life of devices, and poor heat dissipation effect of processing tanks, so as to speed up heat dissipation and improve The effect of improving the service life and improving the overall operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

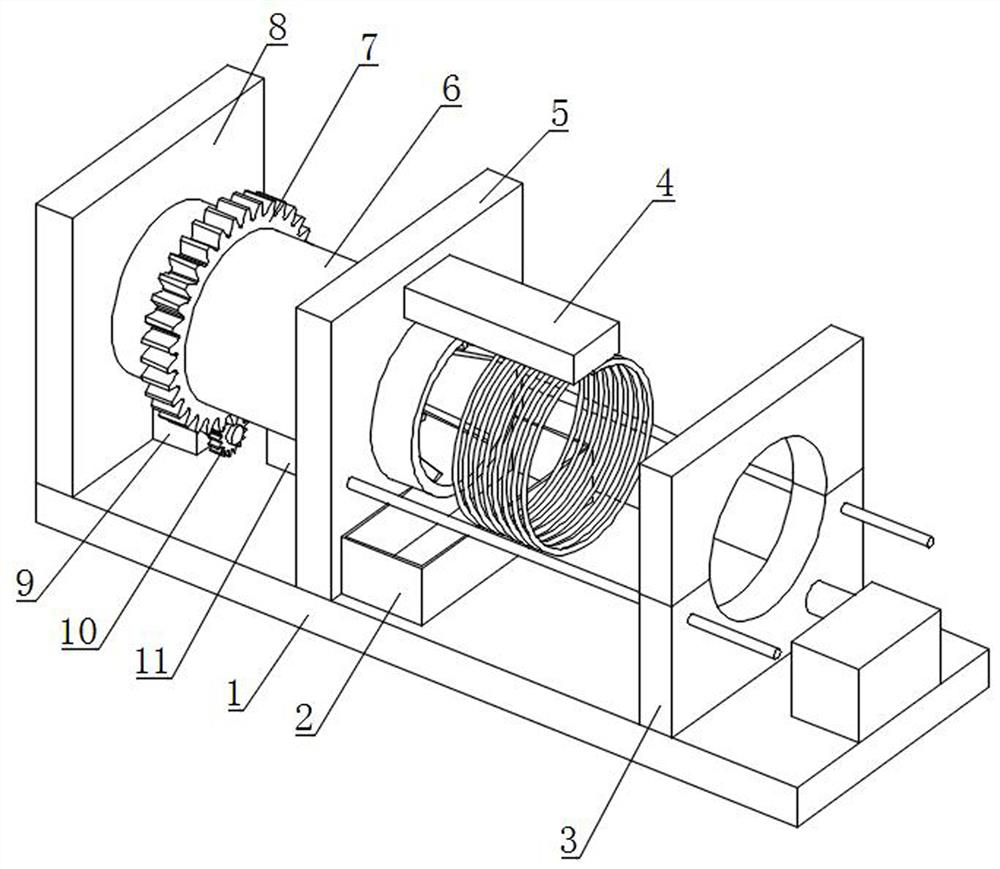

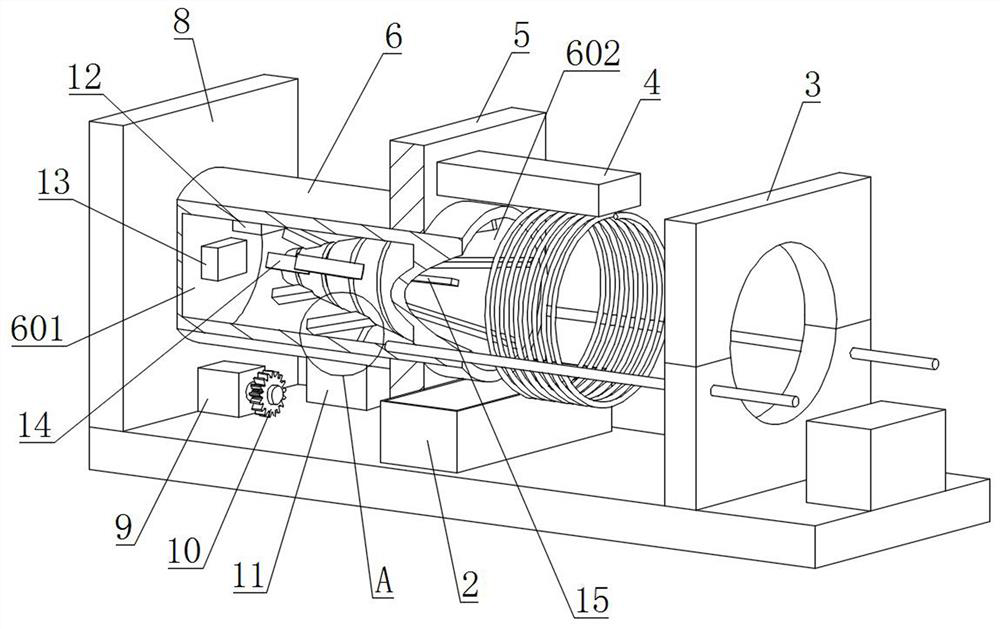

[0028] The main structure of this embodiment, such as Figure 1~3 As shown, it includes a bottom plate 1, a collection box 2, a first support plate 5, a cylinder 6, a second support plate 8, a motor 9, a temperature detector 12, a refrigerator 13, a plurality of cooling fins 14 and a plurality of blades 15; The first support plate 5 and the second support plate 8 are installed side by side on the base plate 1, the first support plate 5 is provided with a heating assembly 4 for heating the workpiece; The mobile component of 3;

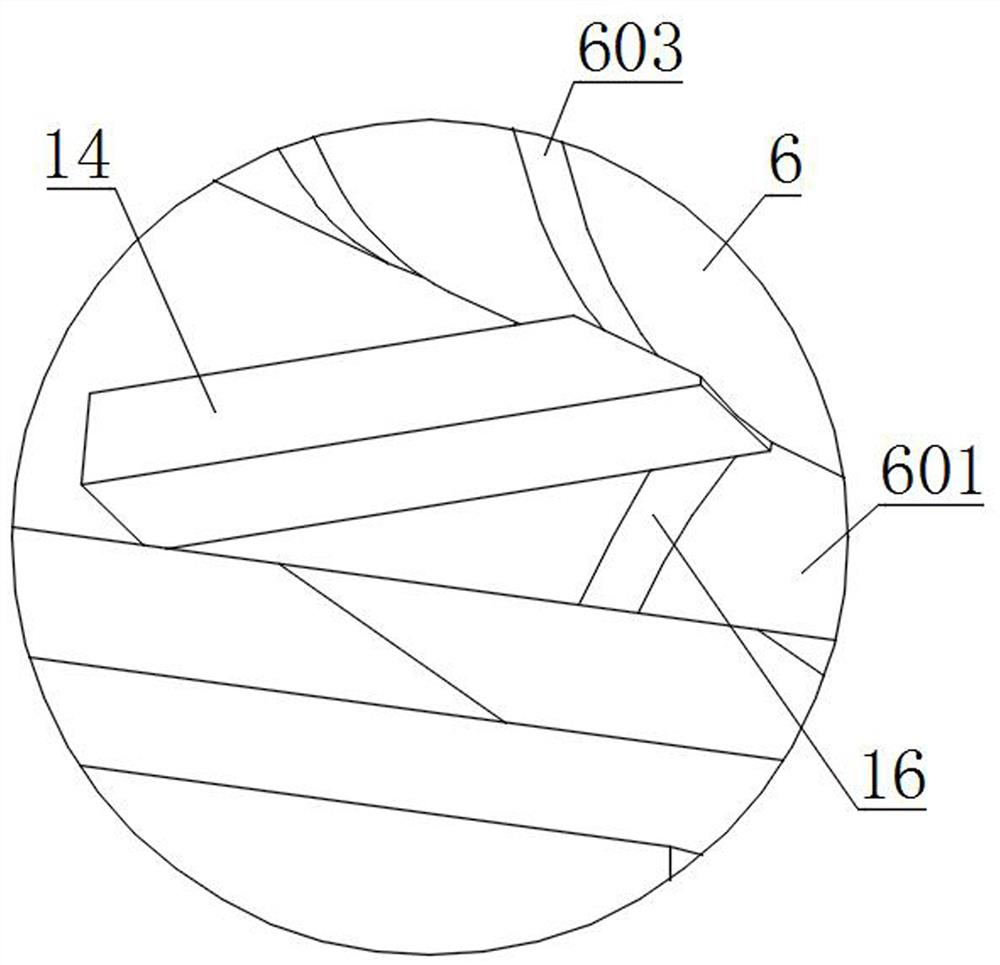

[0029] One end of the cylinder 6 is rotatably connected to the second support plate 8, the other end of the cylinder 6 passes through the first support plate 5, and the end of the cylinder 6 passing through the first support plate 5 is provided with a processing groove 602; The projection shape is conical; the cylinder 6 is provided with an installation warehouse 601; the inner wall of the installation warehouse 601 is provided with a cooling groove 60...

Embodiment 2

[0033] In this embodiment, on the basis of the foregoing embodiments, a vacuum cleaner 11 and a connecting pipe 16 are further added, such as Figure 1~3 As shown; the vacuum cleaner 11 is installed on the cylinder 6; one end of the connecting pipe 16 is connected to the air inlet port of the vacuum cleaner 11, and the other end of the connecting pipe 16 extends into the processing tank 602. Start the vacuum cleaner 11 during use, and the remaining processing debris in the processing tank 602 is sucked in the vacuum cleaner 11 through the connecting pipe 16, and the inside of the processing tank 602 is cleaned to prevent the debris from adhering to a plurality of blades 15. Multiple blades 15 are protected. Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

Embodiment 3

[0035] On the basis of the foregoing embodiments, this embodiment further includes a driving gear 10 and a driven gear 7; the driving gear 10 is mounted on the output shaft of the motor 9; the driven gear 7 is mounted on the cylinder 6, The driven gear 7 is engaged with the driving gear 10 . The driven gear 7 is meshed with the driving gear 10 so that the transmission of the motor 9 is more stable. Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com