Underground diaphragm wall leakage detection method based on tracer agent

A technology of underground diaphragm wall and detection method, which is applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc. Complicated and other problems, to achieve the effects of stable test results, increased cost, and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

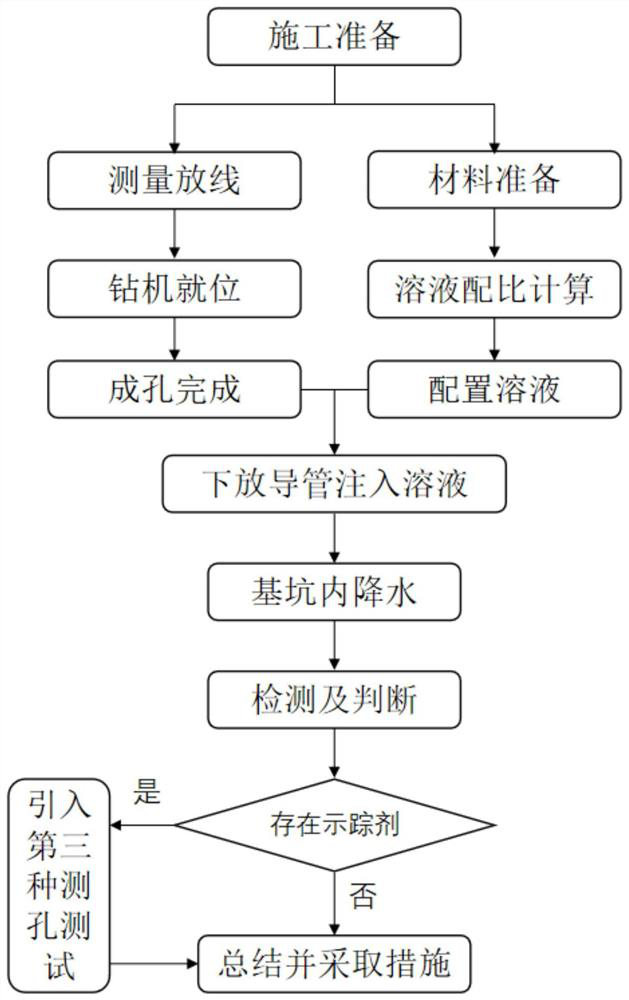

[0038] A kind of underground diaphragm wall seepage detection method based on tracer of the present embodiment, such as image 3 shown, including the following steps:

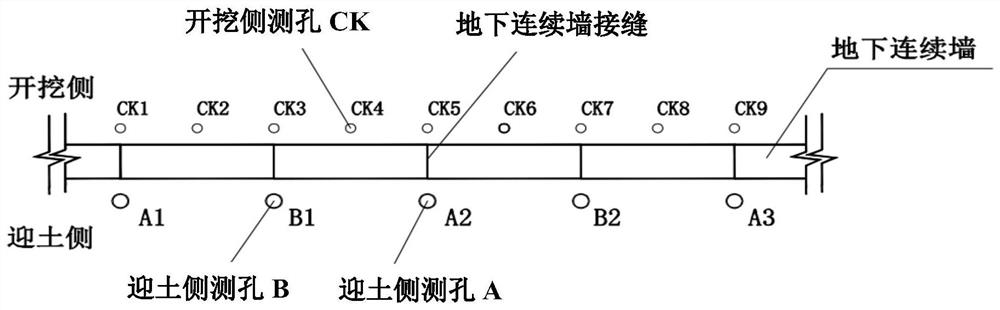

[0039] (1) Layout measuring holes

[0040] Such as figure 1 As shown, the measuring holes A1-A3 and B1-B2 are arranged on the side facing the soil of the underground diaphragm wall, and the measuring holes A and B are arranged as jump holes. At the same time, the measuring holes CK1-CK9 are arranged on the excavation side of the underground diaphragm wall; among them, The depth of each measuring hole is the distance from the ground to the bottom of the foundation pit, and the measuring holes are arranged in parallel at a range of 1-2m from the joint of the underground diaphragm wall. The vicinity of the slit is beneficial to improve the detection sensitivity.

[0041] Specifically, the measuring holes CK1-CK9 are arranged at the joints and the middle of the underground diaphragm wall, and the measuring holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com