Atomizing core capable of improving atomizing effect

A technology of atomizing core and heating sheet, which is applied in the direction of tobacco, etc., can solve the problems of reducing the heat capacity of the substrate, poor atomization effect, and large heating area of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

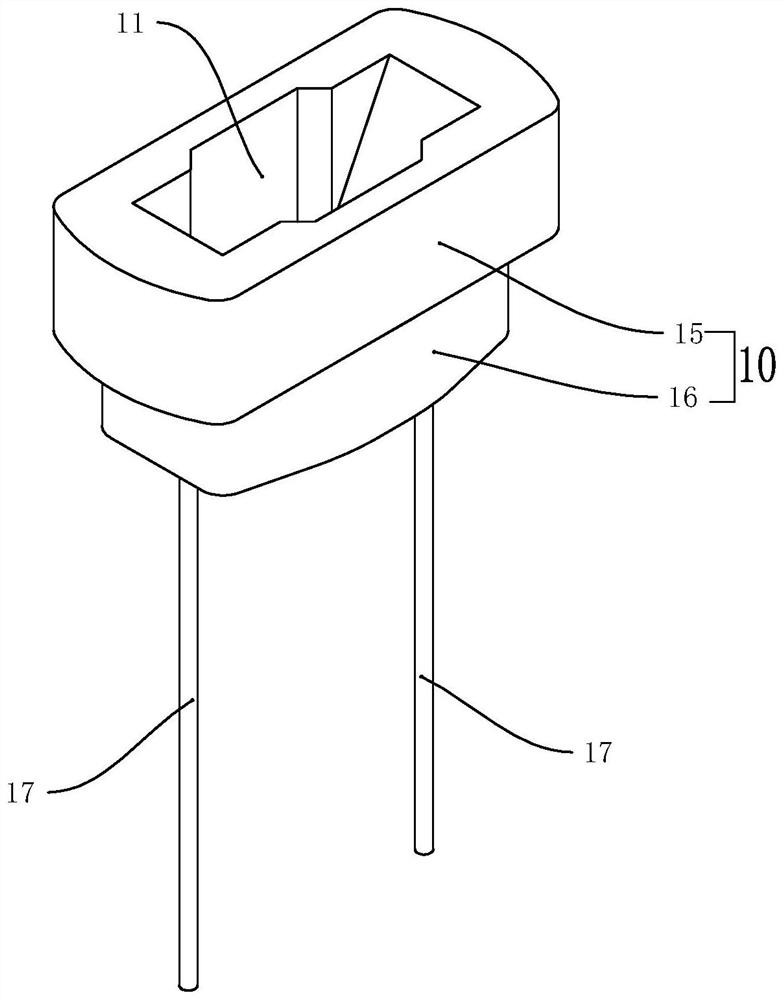

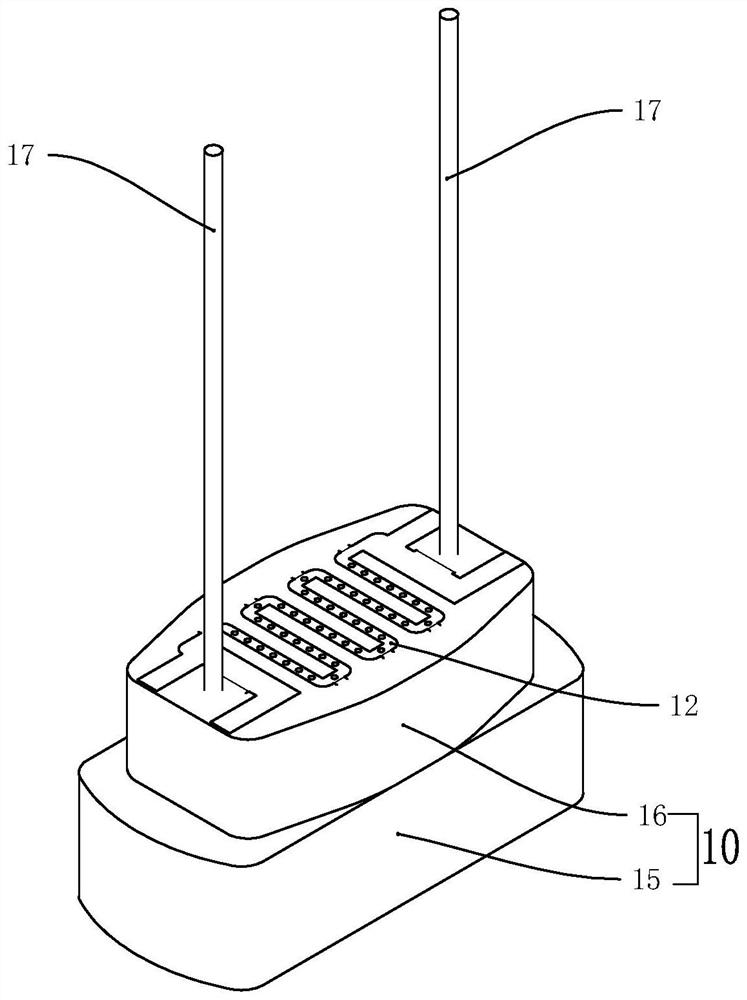

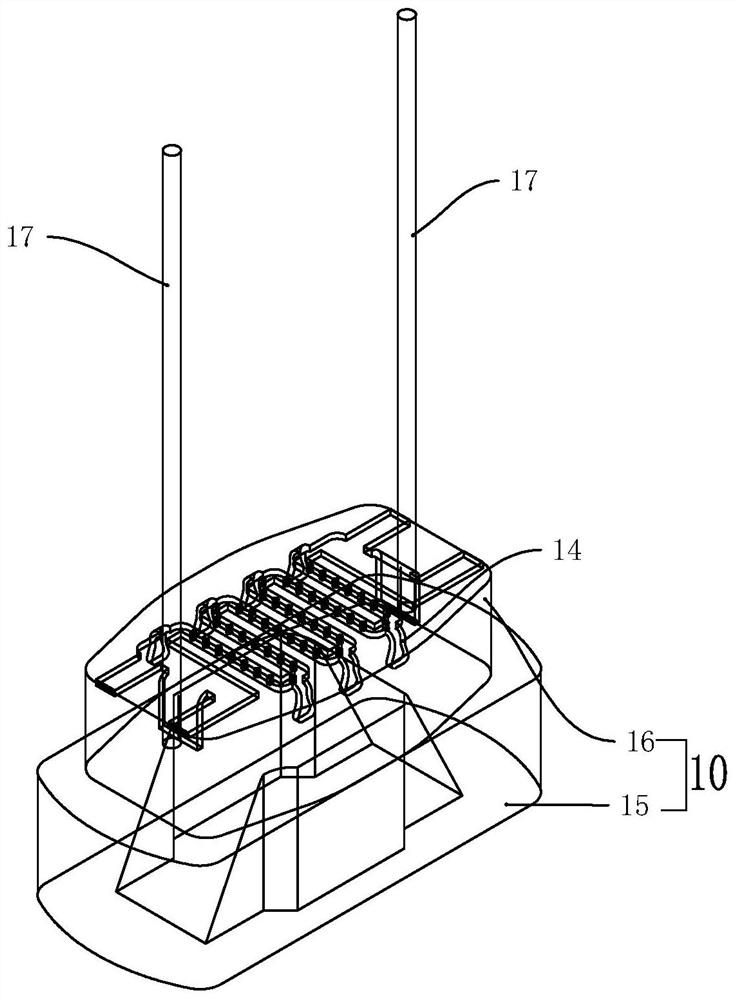

[0022] Such as Figure 1 to Figure 5 As shown, an atomizing core for increasing the atomization effect includes a ceramic base 10, the upper surface of the ceramic base 10 is provided with an oil inlet groove 11, and the lower surface of the ceramic base 10 is provided with a heating sheet 12. The heating sheet 12 is provided with a number of oil guide holes 13 . The e-liquid in the oil inlet tank 11 penetrates into the bottom of the ceramic base 10, and the heat emitted by the heating sheet 12 atomizes the e-liquid. The quantity of 13 is a lot, can set according to need, the oil guide hole 13 has increased the contact area of e-liquid and heating plate 12, and oil guide hole 13 has increased oil guide simultaneously, has increased atomization effect.

[0023] Such as F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com