Assembling equipment for brake caliper piston and dust cover and using method thereof

A technology for assembling equipment and brake calipers, which is applied in metal processing equipment, manufacturing tools, metal processing, etc., can solve the problem of difficulty in ensuring the coaxiality of the piston of the brake caliper, eccentric wear and scratching of the piston and the dust cover, and affect the use of the product Performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

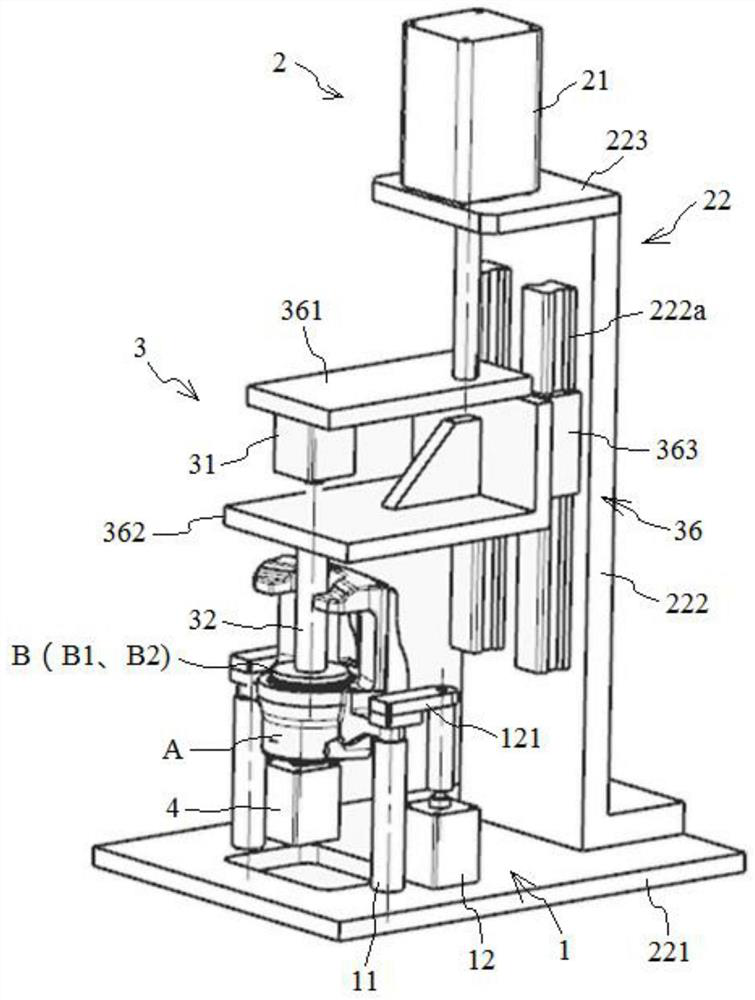

[0031] Please refer to figure 1 , figure 2 , figure 1 It is a structural schematic diagram of a specific embodiment of the assembly equipment of the brake caliper piston and the dust cover provided by the present invention, figure 2 It is the relative position diagram of the positioning device and the pre-assembled parts.

[0032] Such as figure 1 , figure 2 As shown, the present invention provides an assembly device for a brake caliper piston and a dust cover, which is used to assemble the brake caliper piston and the dust cover into a brake caliper body, including a positioning device 1, a lifting device 2 and an adjusting device The positioning device 3 and the positioning device 1 are used for positioning and installing the brake caliper body A, and the brake caliper body A is provided with a cylinder hole (not shown in the figure).

[0033] Further, the positioning device 3 is connected with the lifting device 2, and can be lifted and lowered under the action of t...

Embodiment 2

[0059] For the assembly equipment of the brake caliper piston and the dust cover involved in the various implementations in the first embodiment, the following embodiments of the present invention also provide a method for using the assembly equipment, which specifically includes the following steps:

[0060] Step S1, positioning and installing the brake caliper body A on the positioning device 1;

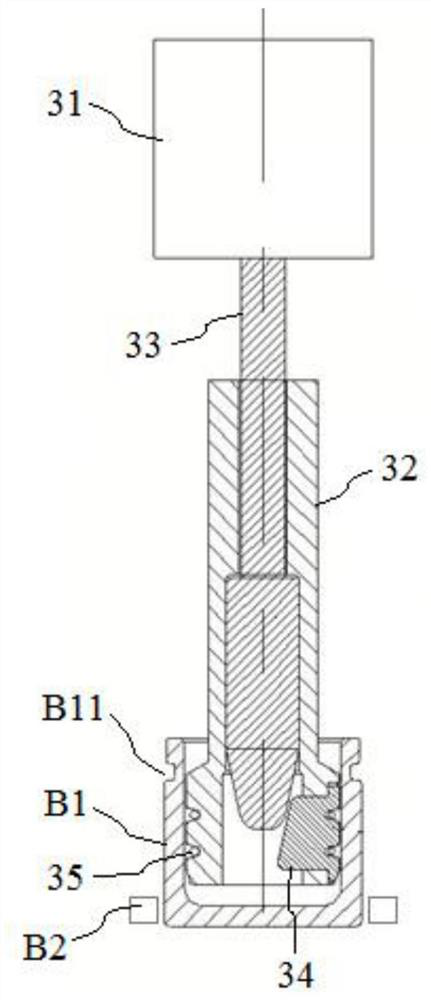

[0061] Step S2, covering the to-be-assembled dust cover B2 on the to-be-assembled brake caliper piston B1 to form a pre-assembled part B, and placing the pre-assembled part B at the cylinder hole of the brake caliper body A;

[0062] Both the above step S1 and step S2 can be completed manually, and there is no order of the two in the implementation process.

[0063] Step S3, start the lifting device 2, so that the positioning cylinder 32 of the positioning device 3 can be inserted into the piston hole of the brake caliper piston B1 to be assembled;

[0064] Step S4, start the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com