Lightweight energy-saving hub unit with ABS sensor

A hub unit, energy-saving technology, applied in the field of vehicle engineering, can solve problems such as cumbersome processes, unfavorable vehicle hub maintenance efficiency, and hub unit damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

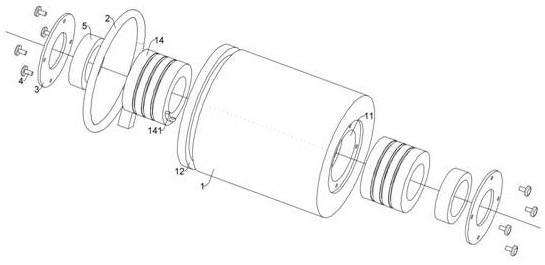

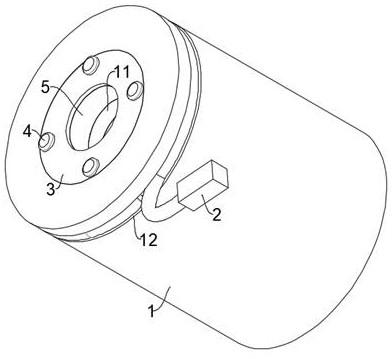

[0035] This embodiment provides a light-weight and energy-saving hub unit with an ABS sensor, which is mainly used to solve the cumbersome process of replacing and maintaining the existing hub unit, which is not conducive to improving the maintenance efficiency of the vehicle hub, and is easy to damage during the disassembly process. The problem of damage caused by the hub unit.

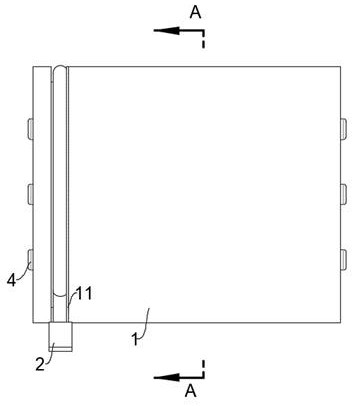

[0036] refer to figure 1 and Figure 4 and Figure 5 As shown, the hub unit plays the role of bearing axial load and radial load during the rotating operation of the drive shaft. The strength of the hub unit is very high during the working process, and it is necessary to ensure the service life of the hub unit. In order to solve this kind of problem, In this embodiment, a hub unit includes a hub body, the hub body includes a hub body 1 and an outer sleeve 7, an annular groove 13 is formed between the hub body 1 and the outer sleeve 7, and the outer The inner sleeve of the shaft sleeve 7 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com