Roller repair method and roll

A roll-one-roller technology, applied in the field of roll repair, can solve problems such as damage to the base of the roll

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

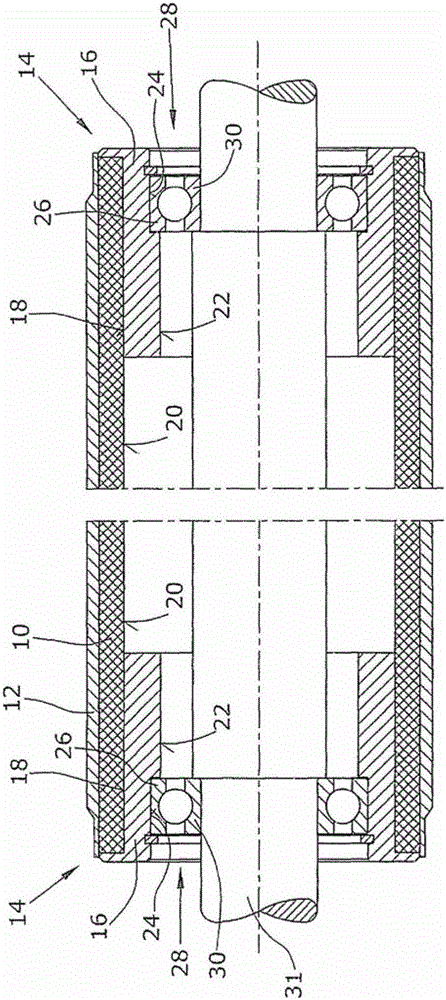

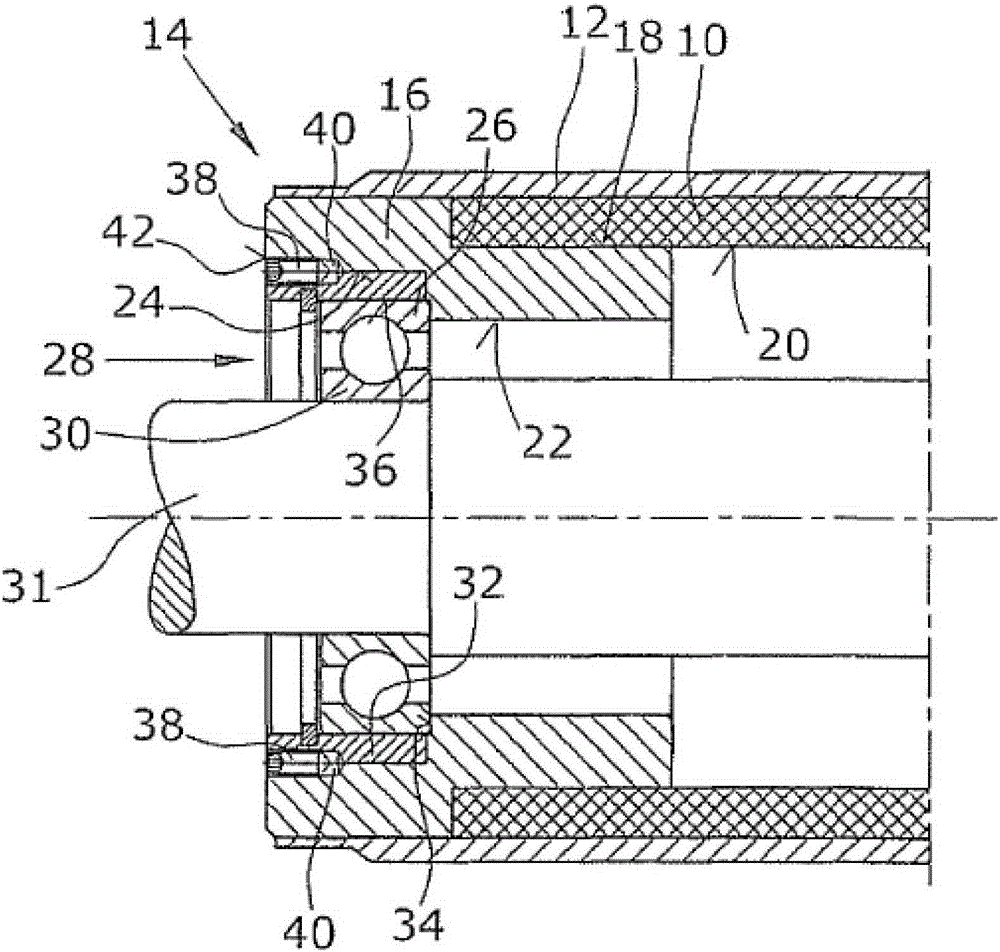

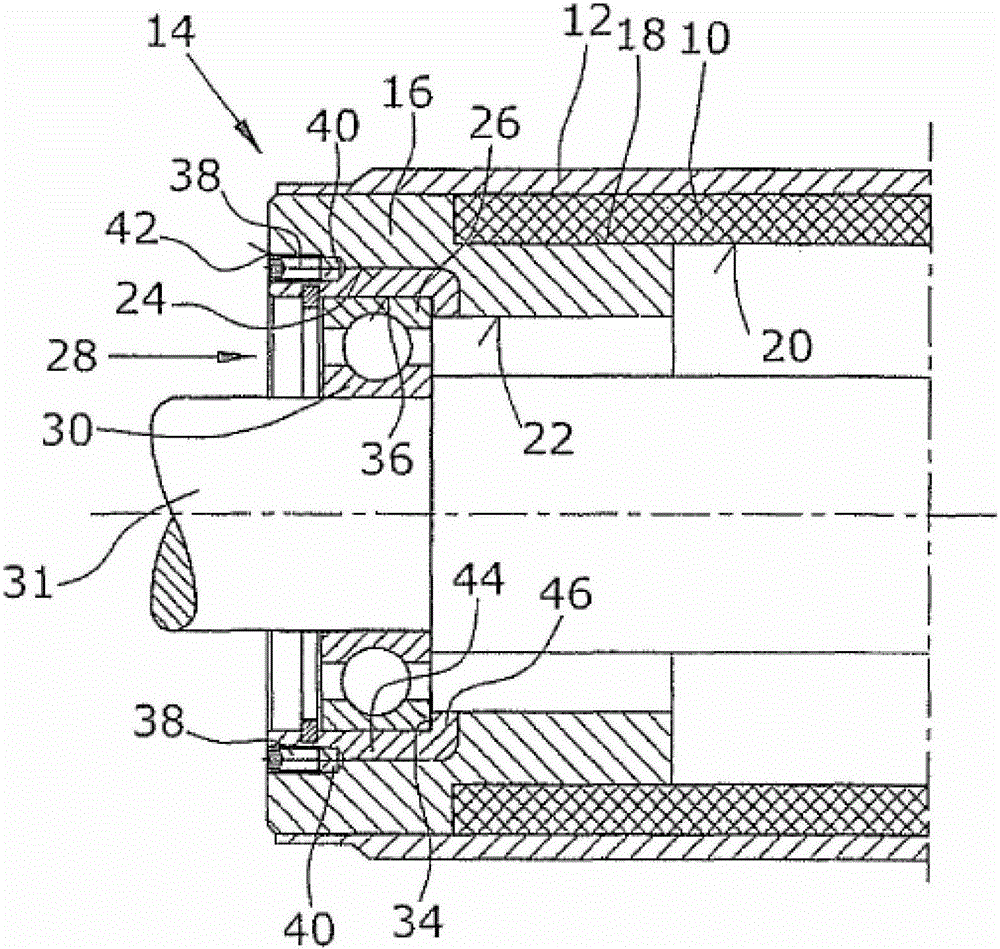

[0025] The roll comprises a cylindrical roller base which can be made of plastic or plastic composite material, for example carbon fiber reinforced plastic or glass fiber reinforced plastic. A cover 12 is provided on the outer surface of the roller base 10 . Depending on the application, this covering can be made of rubber. A bearing carrier assembly 16 is inserted in each of the two end regions 14 of the basic roller body 10 . Typically the bearing bracket assembly 16 is made of steel. The outer side 18 of the bearing bracket assembly 16 is bonded to the inner side 20 of the roller base 10 by bonding. The inner side 22 of the bearing bracket assembly 16 has been ground to form an inner surface 24 which abuts the outer race 26 of the roller bearing 28, the inner race 30 of which is disposed on a shaft 31 which is used for For carrying printing rollers.

[0026] Due to the wear of the cover 12, the cover needs to be replaced at regular intervals. In this way, the cover 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com