Universal aircraft fuselage jack

A technology of aircraft fuselage and jack, which is applied in aircraft maintenance, mechanical equipment, lifting devices, etc. It can solve the problems of limited weight range, inability to fit the aircraft fuselage to lift support, and inability to adapt to the weight of the aircraft fuselage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

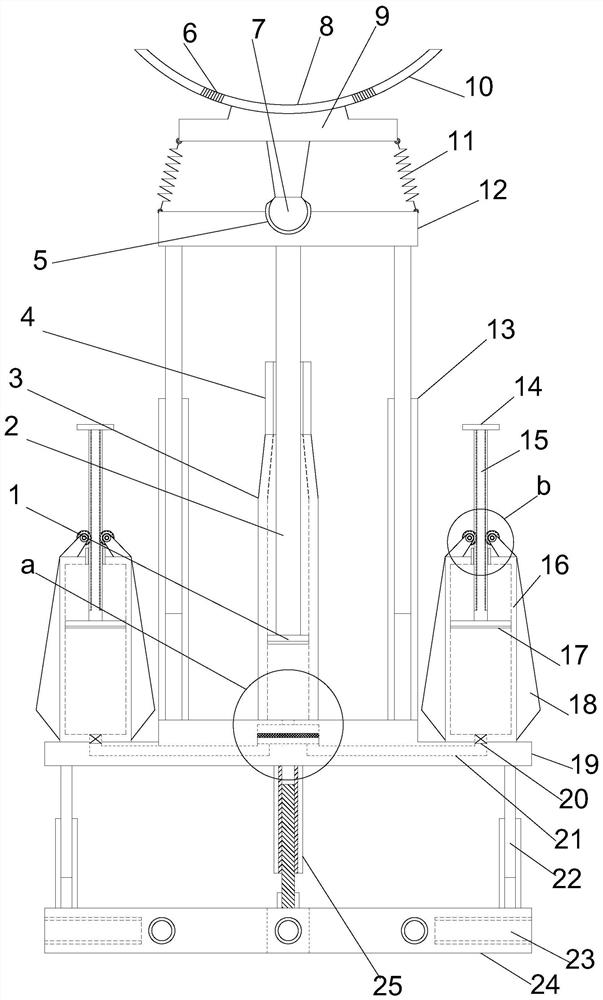

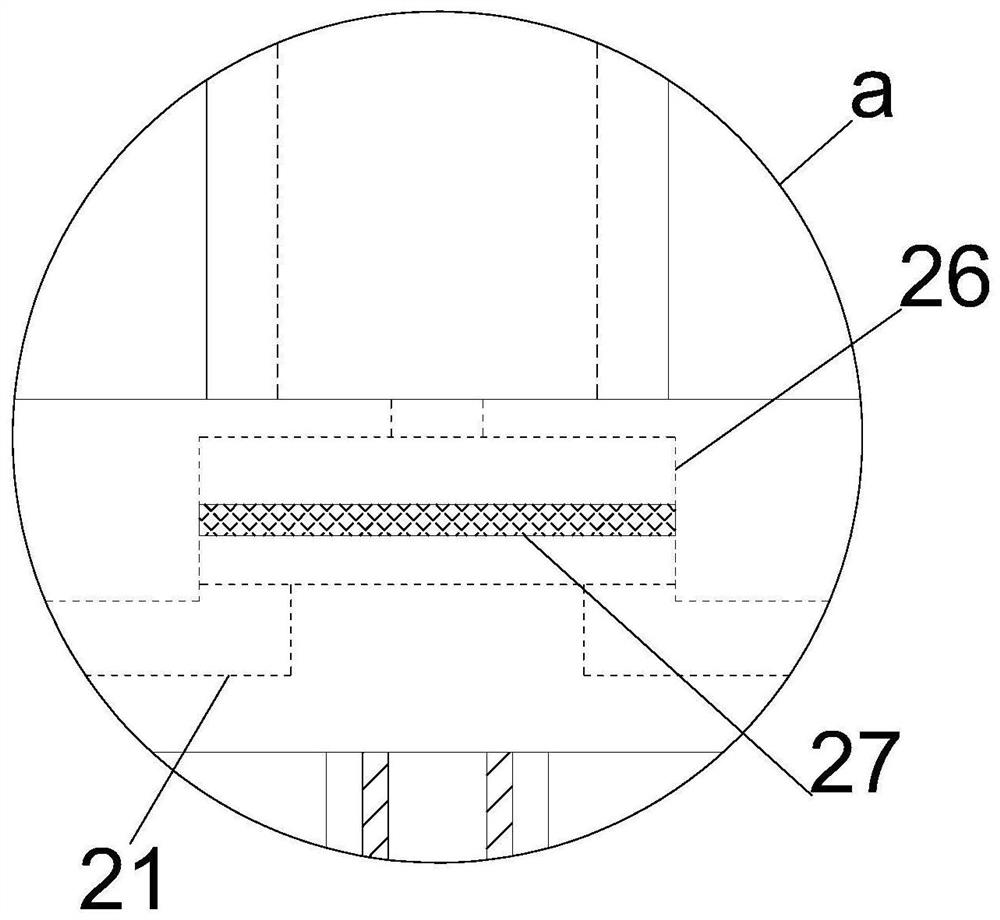

[0024] see Figure 1~4 , in an embodiment of the present invention, a general-purpose aircraft fuselage jack includes a support mounting plate 24, and one side of the support mounting plate 24 is directly provided with a lifting mounting plate 19, and also includes: an adjusting lifting mechanism, which is arranged on the supporting mounting plate 24 and the lifting mounting plate 19; one side of the lifting mounting plate 19 is provided with a combined lifting support module; the combined lifting supporting module includes a combined hydraulic lifting mechanism and an adaptive support mechanism, and the combined hydraulic lifting mechanism is installed on the lifting On the mounting plate 19 , an arc-shaped support plate 8 is provided on the other side of the swing support plate 9 , and the two ends of the arc-shaped support plate 8 are symmetrically provided with a fitting support plate 10 through the elastic reset assembly 6 .

[0025] The lifting installation plate 19 coop...

Embodiment 2

[0027] On the basis of Embodiment 1, the adjustable lifting mechanism includes a power assembly, the power assembly is arranged on the supporting mounting plate 24, one end of the power assembly is provided with a lifting assembly, one end of the lifting assembly is connected with the lifting mounting plate 19, and the lifting mounting plate 19 and the support mounting plate 24 are connected by several stable guide assemblies 22 .

[0028] The edge of the supporting mounting plate 24 is provided with several guiding mounting grooves 23, and the guiding mounting grooves 23 are provided with guiding mounting columns 32, and the outer ends of the guiding mounting columns 32 are provided with extended supporting plates 33.

[0029] Through the coordinated installation of the guide installation groove 23 and the guide installation column 32, the installation of the extended support plate 33 is realized, the support area of the device is expanded, the stability of the upgrade devic...

Embodiment 3

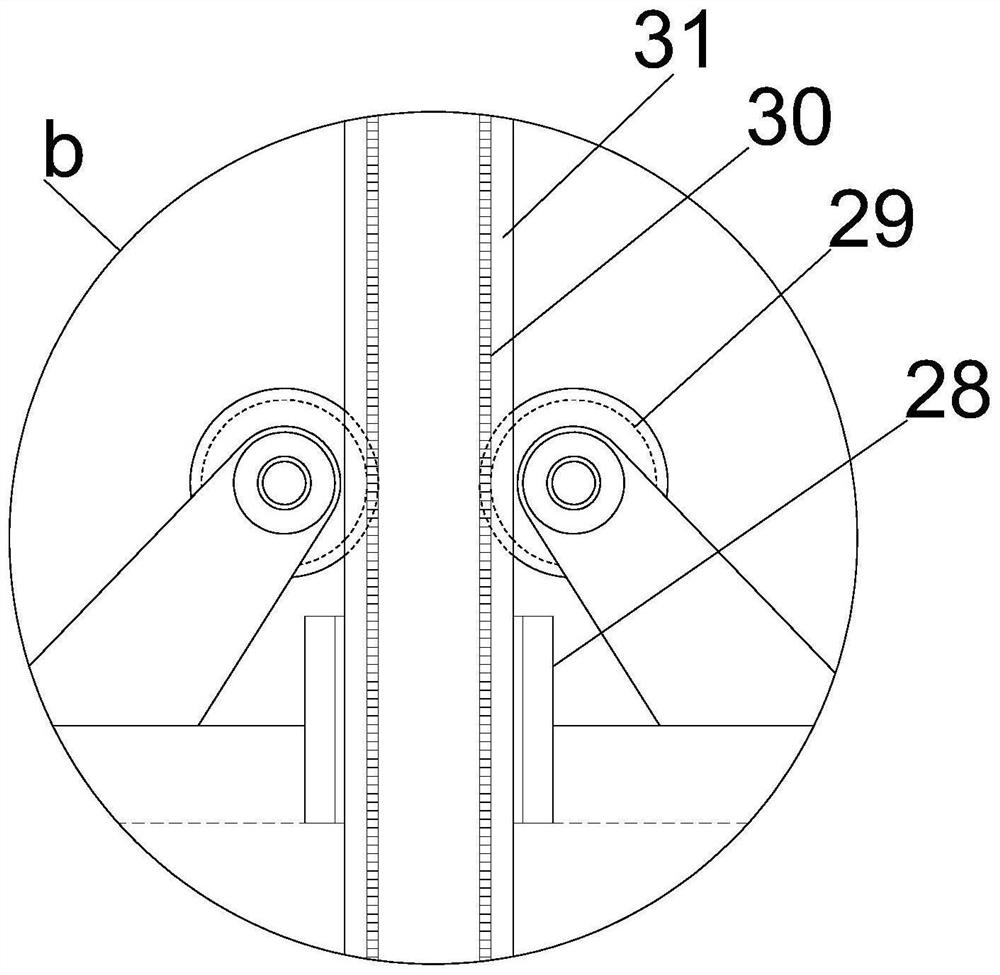

[0032] On the basis of Embodiment 2, the combined hydraulic lifting mechanism includes a lifting hydraulic cylinder 3, one end of the lifting hydraulic cylinder 3 is fixed on the lifting installation plate 19, and the other end of the lifting hydraulic cylinder 3 is provided with a working guide cylinder 4, which cooperates with the operation The guide cylinder 4 is provided with an operation guide column 2, one end of the operation guide column 2 is provided with an operation piston 1 in conjunction with the inner wall of the lifting hydraulic cylinder 3, and the other end of the operation guide column 2 is provided with an operation lifting plate 12, and the operation lifting plate 12 is connected with the lifting installation plate. 19 are connected by several lifting guide assemblies 13.

[0033] One side of the lift mounting plate 19 cooperates with the lift hydraulic cylinder 3 to be provided with several independent hydraulic cylinders 16, one end of the independent hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com