A kind of carboxymethyl chitosan/formylated carboxymethyl cellulose composite film and preparation method thereof

A technology of carboxymethyl chitosan and carboxymethyl cellulose is applied in the field of carboxymethyl chitosan/formaldehyde carboxymethyl cellulose composite film and its preparation, which can solve problems such as toxicity and achieve enhanced antibacterial properties. , The effect of preventing microbial contamination and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

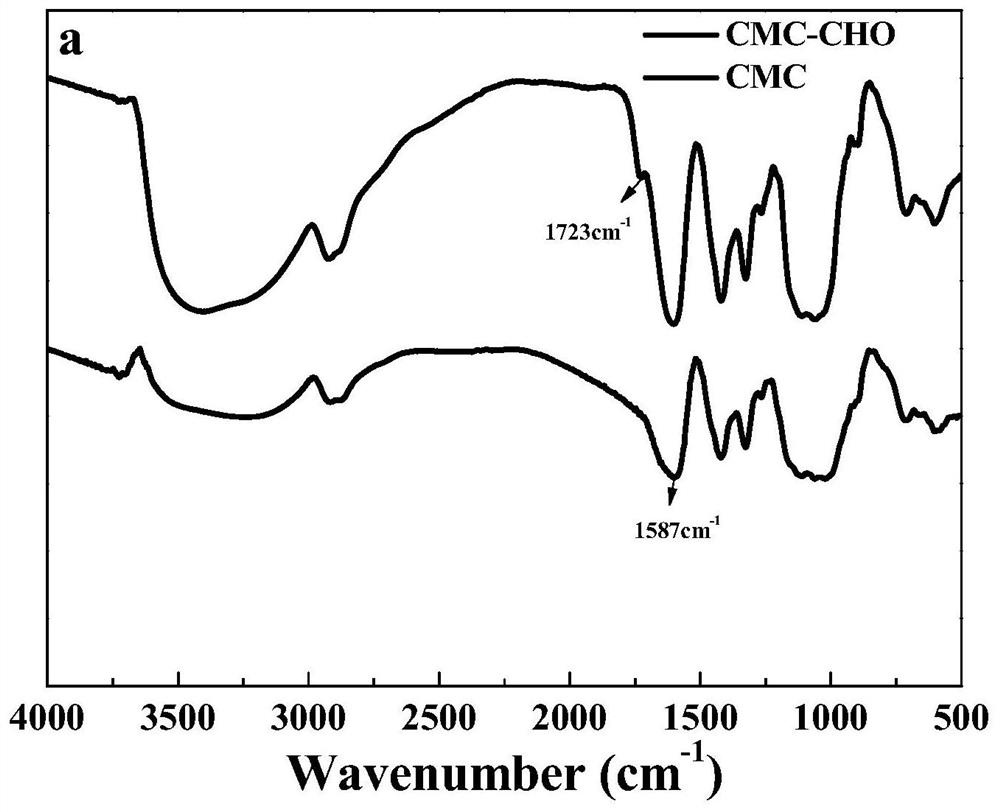

[0035] (1) Dissolve carboxymethylcellulose in water, stir at 30°C to form a carboxymethylcellulose solution with a mass fraction of 0.5%, and place it in a round-bottomed flask. Dissolve 1.5 times mol of sodium periodate in deionized water, shake to dissolve and add to a round bottom flask. The flask was wrapped in tin foil and protected from light. After 2.5 h of reaction, 8 mL of ethylene glycol was added to terminate the reaction for 1 h. The reaction solution was put into a 3500Da dialysis bag and purified by dialysis in deionized water for 72 hours. The water was changed every 12 hours. After three days, it was concentrated by rotary evaporation. Hydroformylated carboxymethyl cellulose with a degree of hydroformylation of 13%.

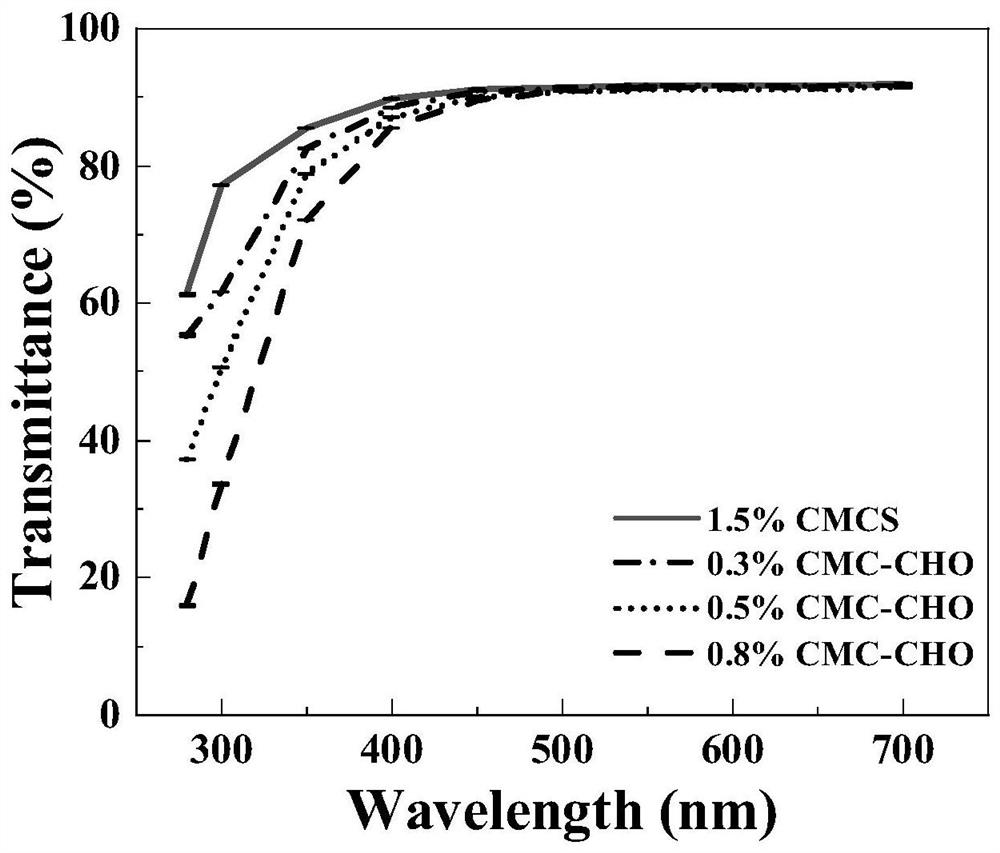

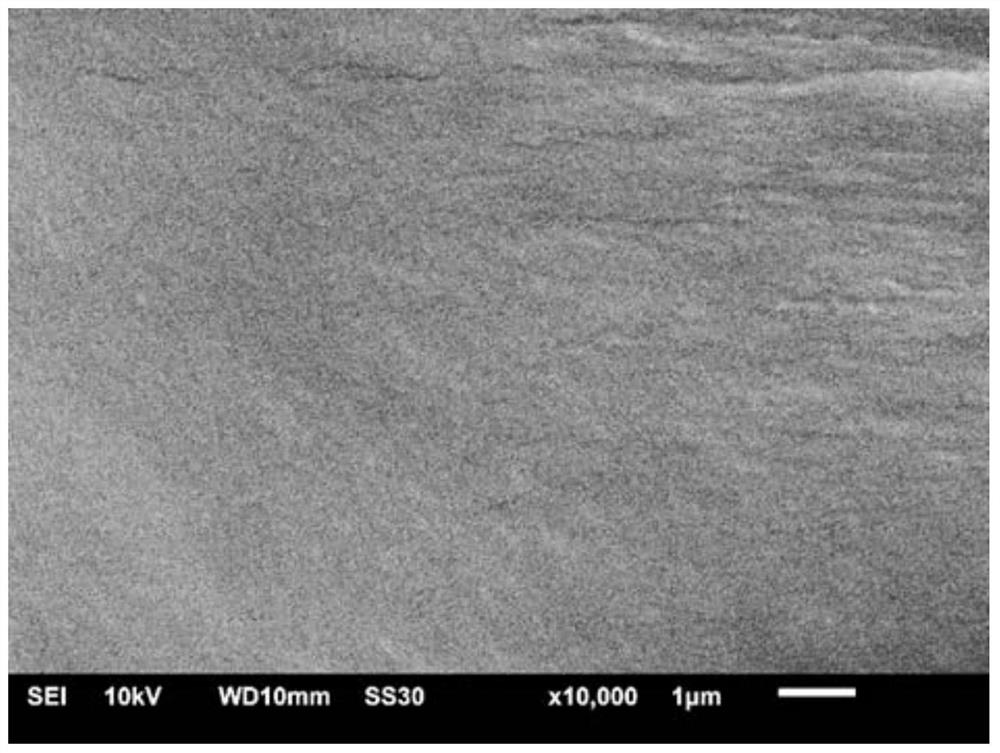

[0036] (2) get carboxymethyl chitosan (CMCS) to be dissolved in water respectively and form the carboxymethyl chitosan solution that mass fraction is 1.5%, 2.0%, 2.5%, then add appropriate amount of formaldehyde carboxymethyl cellulose, make Th...

Embodiment 2

[0045] (1) Dissolve carboxymethylcellulose in water, stir at 30°C to form a carboxymethylcellulose solution with a mass fraction of 0.8%, and place it in a round-bottomed flask. Dissolve 2 times mol of sodium periodate in deionized water, shake to dissolve and add to a round bottom flask. The flask was wrapped in tin foil and protected from light. After 2.5 h of reaction, 10 mL of ethylene glycol was added to terminate the reaction for 1 h. The reaction solution was put into a 3500Da dialysis bag and purified by dialysis in deionized water for 72 hours. The water was changed every 12 hours. After three days, it was concentrated by rotary evaporation. Hydroformylated carboxymethyl cellulose with a degree of hydroformylation of 15%.

[0046] (2) Dissolve carboxymethyl chitosan in water to form a carboxymethyl chitosan solution with a mass fraction of 2.0%, and then add an appropriate amount of carboxymethyl cellulose (CMC-CHO) to make the coating solution The mass fractions o...

Embodiment 3

[0054] (1) Dissolve carboxymethyl cellulose in water, stir at 30° C. to form a carboxymethyl cellulose solution with a mass fraction of 1%, and put it in a round bottom flask. Dissolve 2.5 times mol of sodium periodate in deionized water, shake to dissolve and add to a round bottom flask. The flask was wrapped in tin foil and protected from light. After 2.5 h of reaction, 12 mL of ethylene glycol was added to terminate the reaction for 1 h. The reaction solution was put into a 3500Da dialysis bag and purified by dialysis in deionized water for 72 hours. The water was changed every 12 hours. After three days, it was concentrated by rotary evaporation. Hydroformylated carboxymethyl cellulose with a degree of hydroformylation of 15%.

[0055] (2) Dissolve carboxymethyl chitosan in water to form a carboxymethyl chitosan solution with a mass fraction of 2.0%, then add an appropriate amount of carboxymethyl cellulose to form carboxymethyl cellulose in the coating solution The pri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com